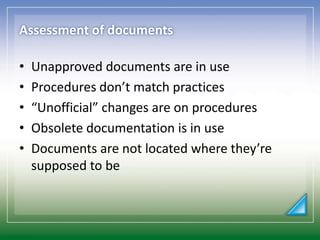

The document discusses quality management systems and ISO 9001. It covers key aspects of a quality management system including continual improvement, management involvement, monitoring customer satisfaction, controlling outsourced processes, identifying non-conformities, corrective and preventive actions, and implementing a quality management system. Diagrams show flows and relationships between various quality management activities and requirements.