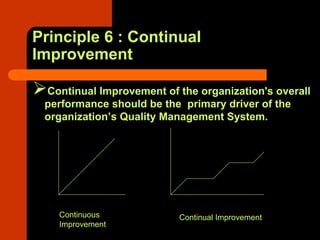

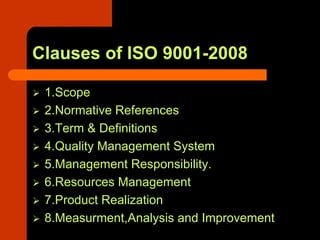

This document provides an overview of ISO 9001:2008. It discusses that ISO 9001 is an international standard for quality management systems. It was created by the International Organization for Standardization to standardize quality systems globally. The standard is based on several quality management principles like customer focus, leadership, involvement of people, and continual improvement. It outlines the requirements for a quality management system, which organizations can implement on a voluntary basis and get certified by external registrars. The standard uses a process approach and is based on Plan-Do-Check-Act cycle of continual improvement.