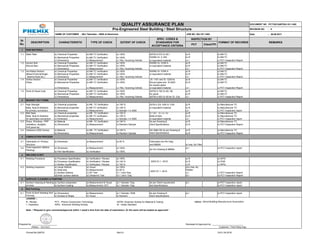

This document outlines a quality assurance plan for pre-engineered steel buildings and steel structures. It specifies inspection requirements for raw materials, fabrication processes, welding, surface cleaning and painting. Raw materials like steel plates, bolts, doors and windows will be verified against specifications. Fabrication like member dimensions and identification will be inspected. Welding procedures, welder qualifications and welding inspections will follow codes like AWS D1.1. Surface preparation and coating thickness will be checked daily. Final inspection will verify dimensions and surfaces before painting according to drawings and standards. Inspection results will be documented in reports.