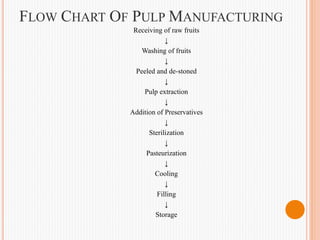

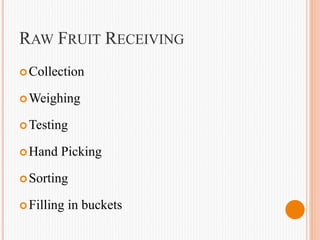

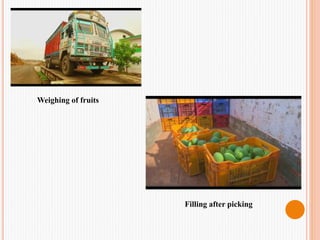

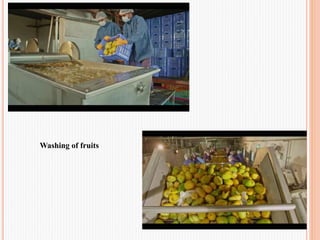

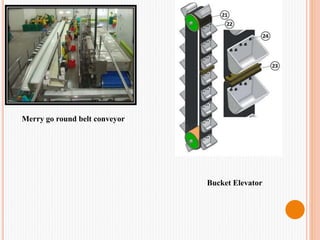

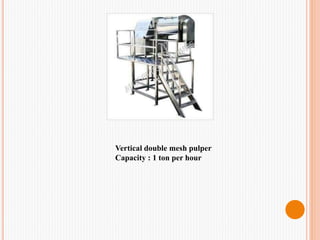

This document provides information on the process of fruit pulp manufacturing, including the steps of receiving, washing, peeling, pulping, adding preservatives, sterilizing, pasteurizing, filling, and storing the pulp. It discusses the machinery used such as fruit washers, conveyors, pulpers, pasteurizers, and packing machines. Finally, it outlines the outcomes of fruit pulping like value addition, increased consumption time, employment, and providing raw materials for other food products.