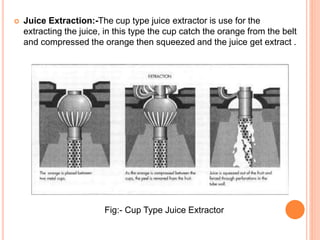

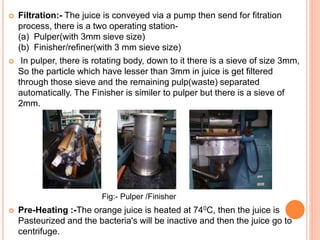

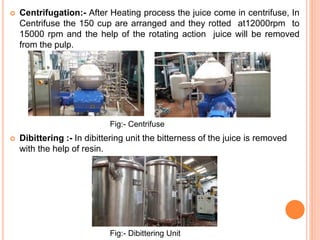

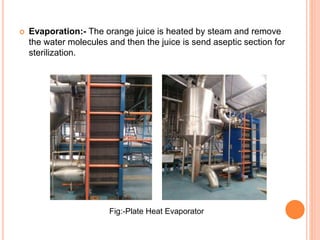

The document discusses the process of orange juice processing. It begins with an introduction to oranges and their origins. It then provides a flow chart of the process which includes receiving, washing, inspection, juice extraction, filtration, pre-heating, centrifugation, dibittering, evaporation, sterilization, filling and storage. Each step is further described with details on equipment used. The document concludes by discussing the health benefits of orange juice such as regulating blood pressure, preventing cancer, and helping with blood circulation, cholesterol balance, skin glow and weight loss.