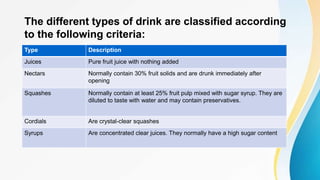

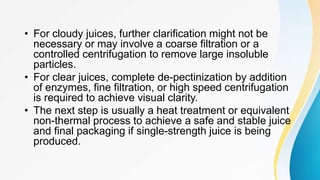

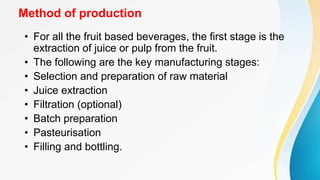

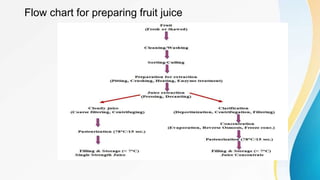

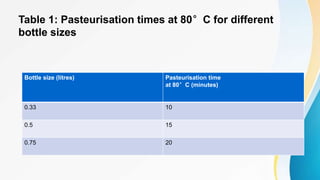

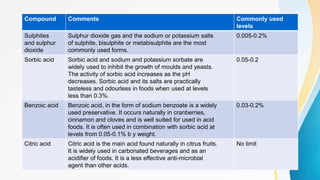

The document discusses the processing of fruit juices and beverages, detailing methods from extraction to bottling. It emphasizes the importance of raw material quality, the use of preservatives for shelf stability, and various production techniques including filtration, pasteurization, and blending. Additionally, it highlights common challenges in juice production, such as oxidation and browning, as well as the role of enzymes in enhancing juice quality.