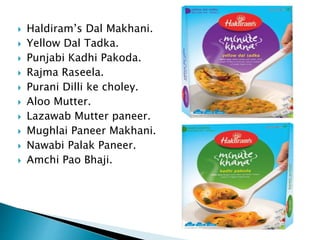

The Haldiram story began in 1937 in Bikaner, India and introduced the brand name "Haldiram Bhujiawala" in 1941. It was led by three brothers and expanded operations by establishing manufacturing units for sweets and snacks in Kolkata in 1950 and Nagpur in 1970. Haldiram offers various Indian snacks and sweets and has become a staple brand in Indian households through uncompromising quality. It produces a wide range of products across multiple sections including ready-to-eat meals, snacks, and bakery items.