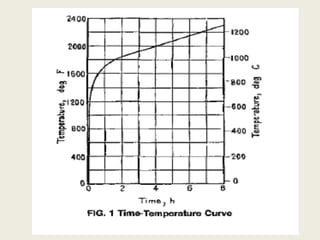

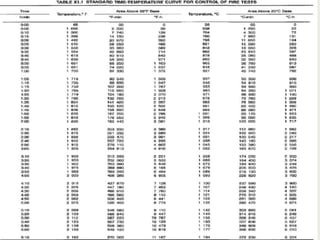

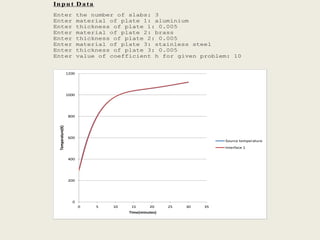

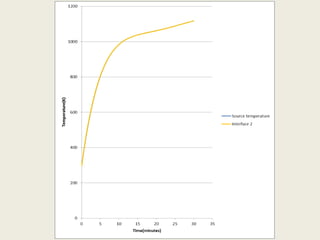

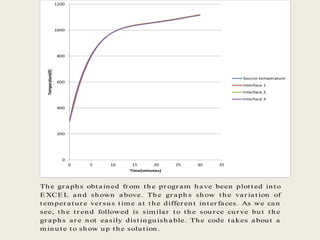

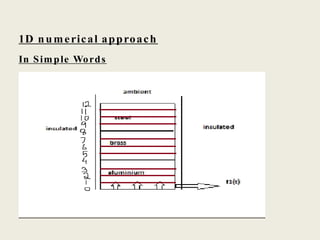

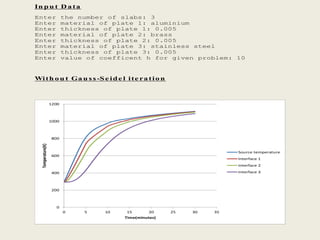

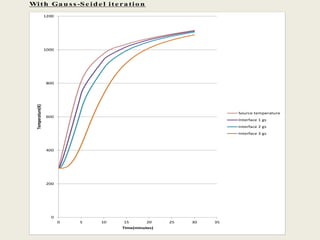

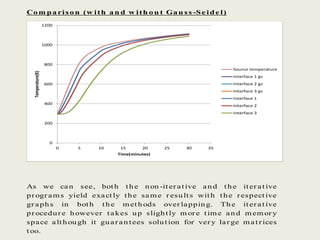

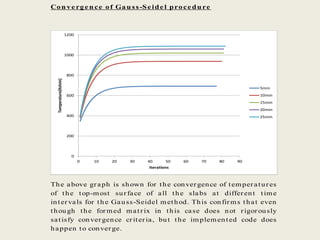

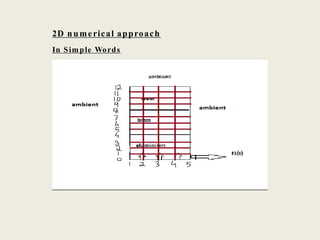

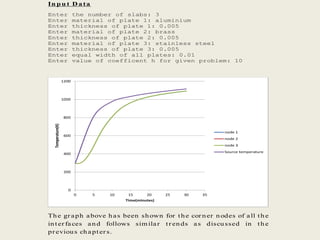

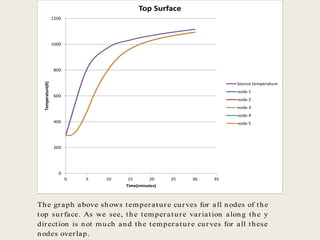

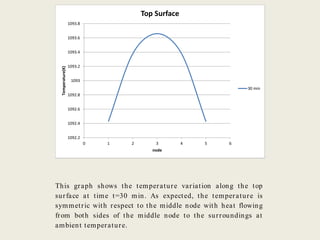

This document describes a simulation tool to model heat transfer through multiple materials. The tool calculates the temperature over time at the interface of each material when the bottom surface is subjected to a temperature curve. The model uses a finite difference approach and implicit time-stepping to solve the heat transfer equations. The equations are solved using both direct matrix inversion and an iterative Gauss-Seidel method, and both solutions are found to match.