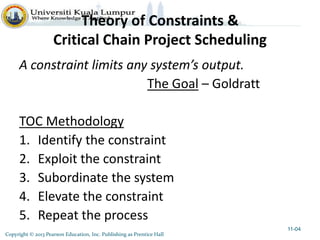

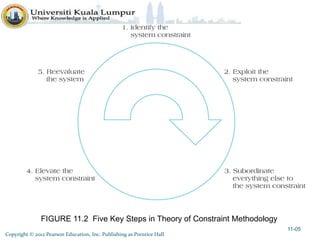

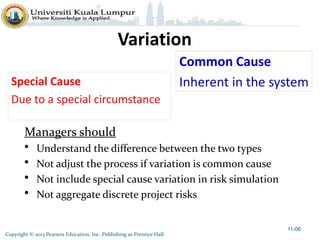

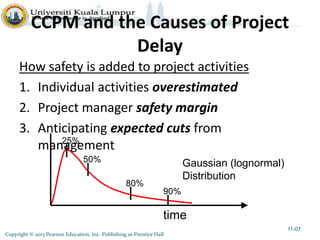

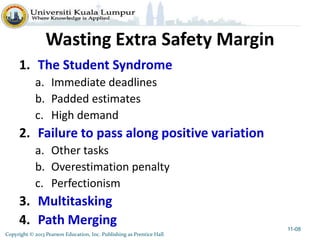

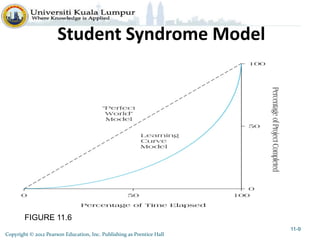

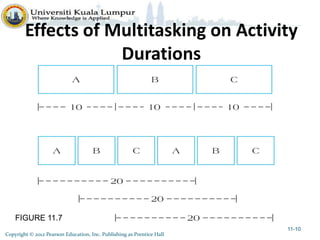

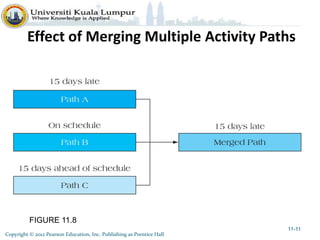

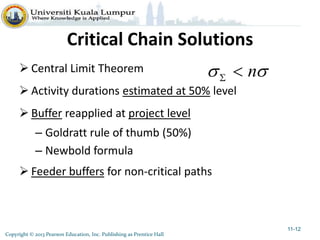

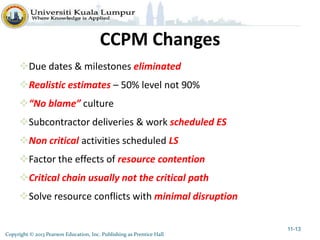

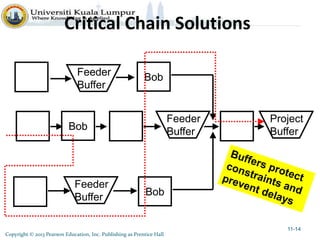

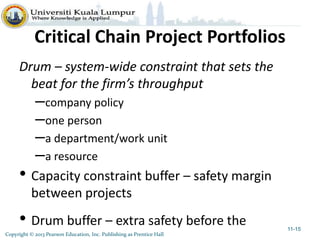

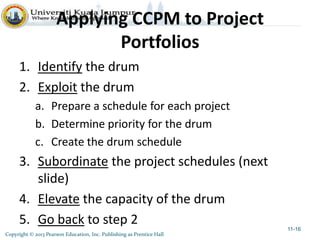

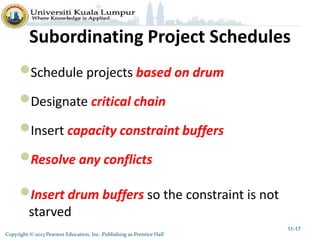

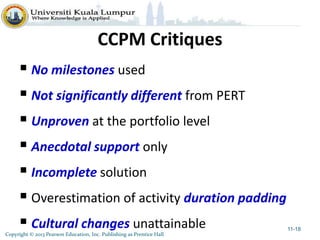

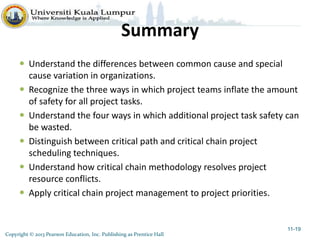

This chapter discusses critical chain project scheduling and the theory of constraints. It explains how critical chain methodology addresses issues like variation, resource conflicts, and wasted safety margins that can cause delays. Key aspects covered include identifying the constraint or bottleneck, exploiting it by prioritizing projects, inserting buffers, and resolving conflicts to maximize throughput within the constraints. The chapter also reviews critiques of critical chain project management.