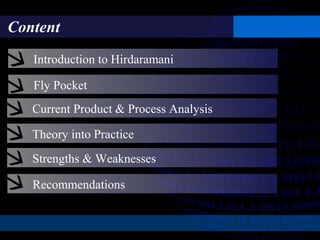

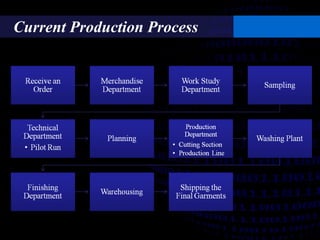

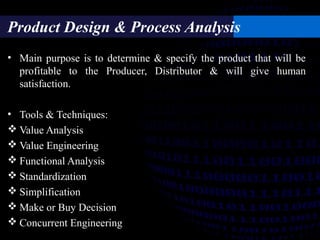

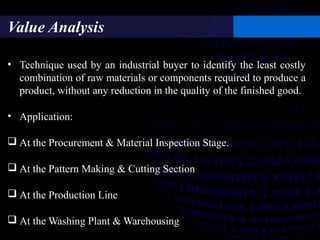

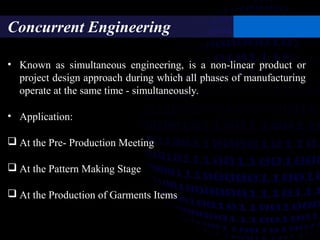

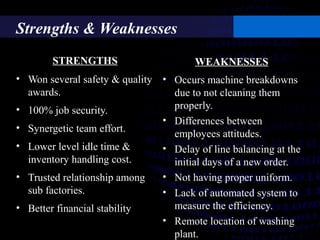

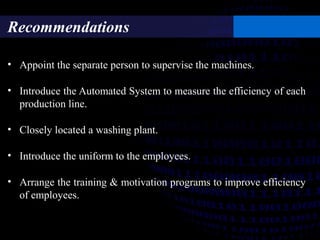

Hirdaramani Industries Ltd. is one of the largest apparel factories in Sri Lanka, exporting woven garments since 2000. It produces garments for brands such as Levi's, Penguin, Adidas, and Columbia. The document analyzes Hirdaramani's current product design and production process for a fly pocket garment produced for Columbia. It identifies strengths like quality awards and job security, and weaknesses like machine breakdowns and differences in employee attitudes. It recommends appointing staff to supervise machines, introducing automated efficiency systems, relocating the washing plant, providing uniforms for employees, and implementing training programs.