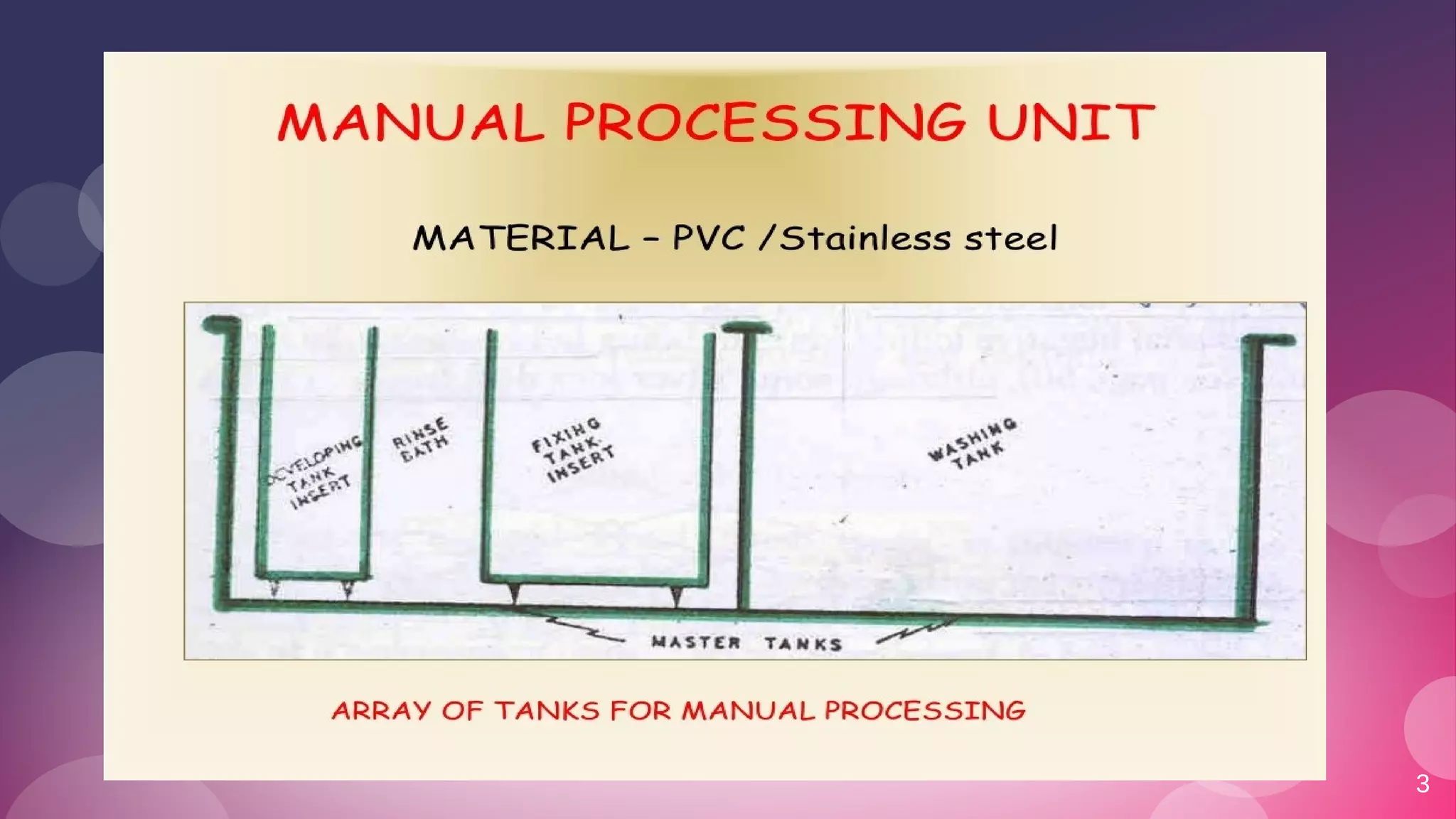

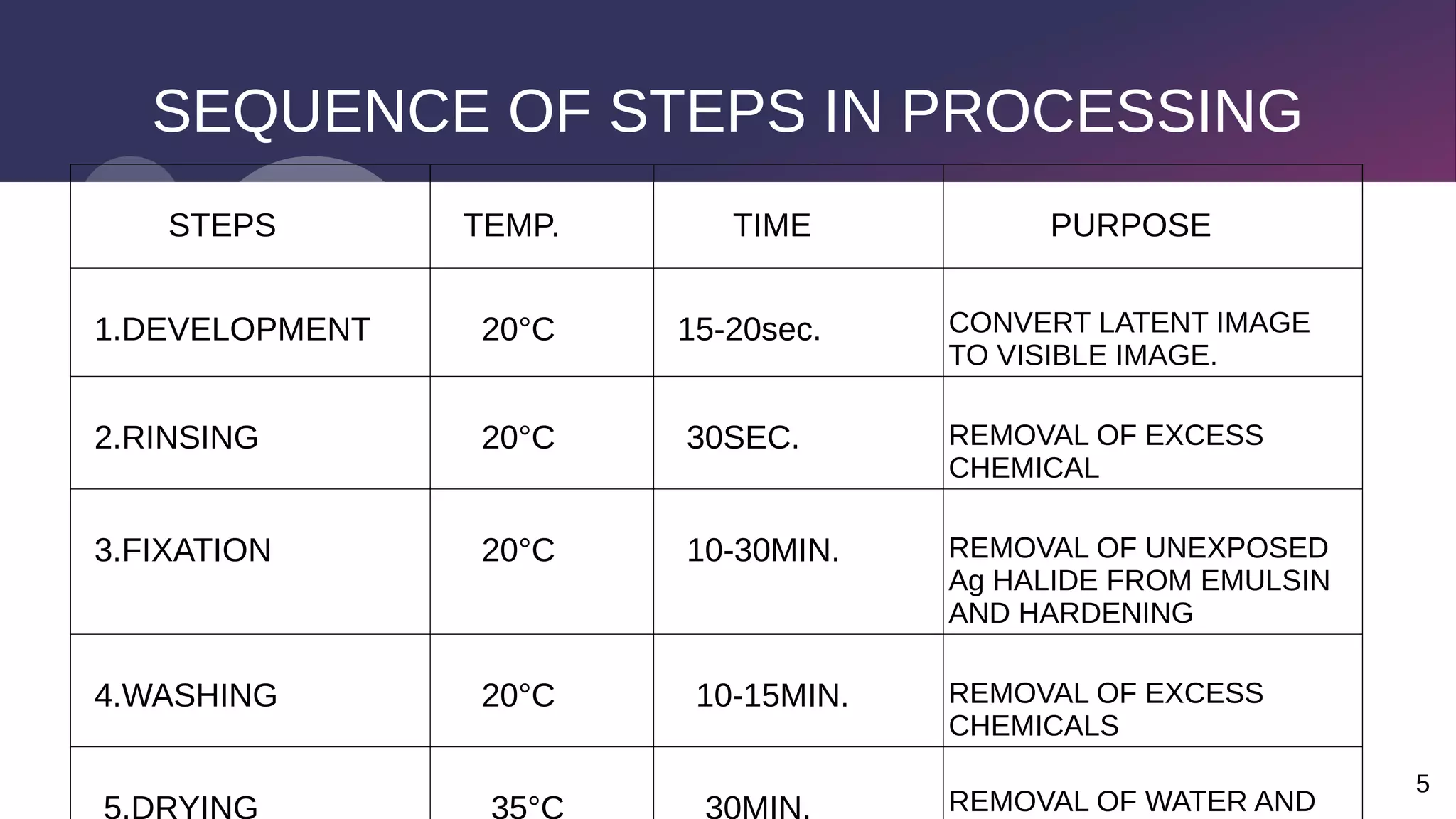

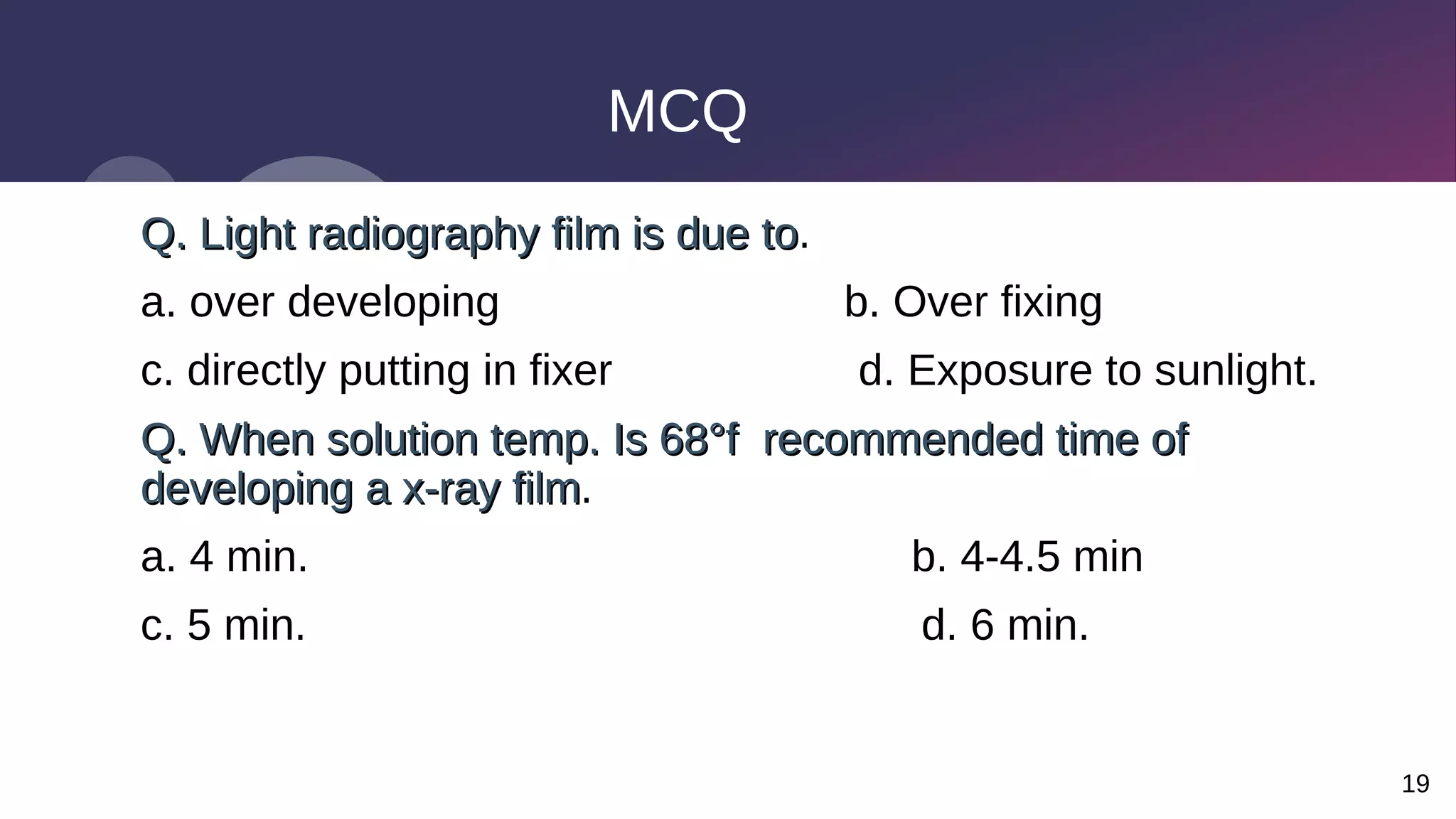

The document discusses the process of developing x-ray films, including the steps of development, fixing, rinsing, washing and drying. Development converts the latent image to a visible image using a developer solution containing components like phenidone and hydroquinone. Fixing dissolves and removes unexposed silver halide using a hypo fixer solution. Other steps such as rinsing, washing and drying are also required to produce the final radiograph.