This document is a processing guide from GBH Enterprises, Ltd. that details methods and considerations for refining and petrochemical industries, particularly focusing on the synthesis and evaluation of various catalyst processes. It includes information on solid-liquid separation techniques, troubleshooting procedures, and catalytic performance assessments, emphasizing the importance of optimized process selection based on physical and economic factors. Additionally, it provides case studies on the harvesting of single-cell proteins and the dewatering of specialty latex, discussing the decision-making processes involved in technology selection.

![(b)

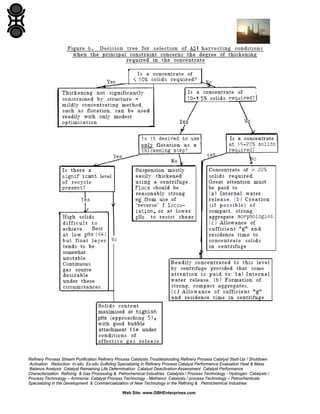

With regard to the latter, it is important not to try to arrive at the final

technological solution too quickly (i.e. in too few iterations) otherwise one

may In fact end up performing an unnecessary amount of physical testing.

Rather it is essential to perform some analysis, whittle down the options,

and then proceed to the next, more detailed stage on a limited front. An

example would be the thickening of slurry to prescribed solids content.

Conceivably flotation, sedimentation, filtration or centrifugation could be

used. Usually it is wise to first measure the network modulus/solids

content relationship for samples at various degrees of thickening.

Inspection of the curve will immediately tell one whether the first TWC

options are "runners" or whether a significant pressure head is needed to

give the desired solids content. Whatever the outcome of the experiment

the number of possibilities will be approximately halved right away.

(c)

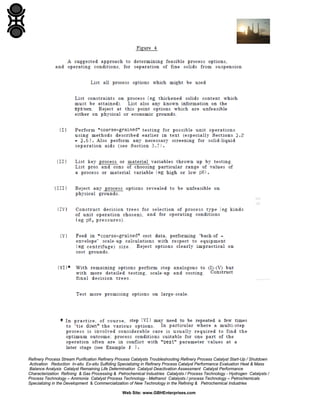

The scheme given In Figure 4 should, if properly employed, yield both the

appropriate choices of unit operation (e.g. flotation, centrifugation) and of

operating conditions (pH, pressures and so on). It should be noted that for

any particular problem there will probably not be one “correct” answer;

rather there will often be a series of possibilities (unit operations and

(linked) operating conditions) which will have particular advantages in

specific circumstances. For example, for thickening problems the route

eventually chosen will depend very much on local factors such as

equipment availability and cost of energy. Accordingly, the object of the

scheme is to derive a series of decision trees from which a selection of

processes can be made on a logical basis.

(d)

Although Chapter 3 has dealt mainly with the physico-chemical factors

governing solid-liquid separation it Is, of course, essential to perform a

parallel study of the process options based upon cost considerations.

Implicitly in Figure 4 it is assumed that this aspect of solving the problem

will be “built-in” right from the beginning to eliminate work on completely

impractical routes. Process synthesis methods for solids separation and

handling are, as yet, rather rudimentary compared with the techniques

available for gas-liquid systems. However, some preliminary studies of

possible methodology have recently been presented by Rossiter [1].

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com](https://image.slidesharecdn.com/processsynthesis-140128170000-phpapp02/85/Process-Synthesis-5-320.jpg)

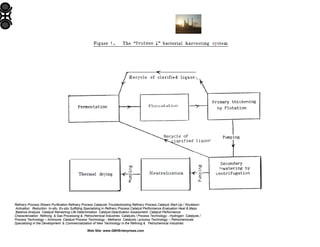

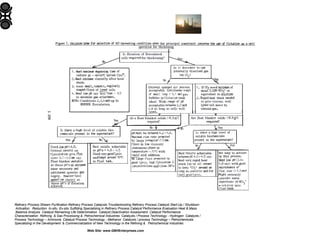

![Attempts at membrane separation had previously proved extremely unpromising

and, due to the strong fouling propensity of the biological suspension, were not

considered further. Instead some kind of conventional mechanical dewatering

seemed inevitable with sedimentation, flotation, centrifugation and filtration all

being runners, either singly or in combination. The small size (~ 1 micron) and

low density (only marginally greater than water) of the bacteria meant, however,

that enlargement of species size, by some kind of flocculation operation, was

required for any of the unit operations to be practical. However, even after

flocculation, due to the near neutral buoyancy of the bacterial aggregates,

sedimentation tended to be very slow probably (but not certainly) ruling it out as

the thickening method. Filtration was also eliminated at an early stage: scouting

filtration studies had been somewhat disappointing owing to floe breakup and

material loss [2]. In addition, filtration was not an operation particularly lending

itself to rapid continuous thickening of a perishable material. Thus at the end of

the first assessment the options were clear: flocculation followed by flotation or

centrifugation, singly or in combination. Sedimentation and filtration were

relegated to a "reserve list", put aside but not entirely forgotten in case the

preferred options proved flawed. Flocculation could either involve components of

the broth (perhaps after pH adjustment to stimulate aggregation) or added floe

agents. However, in the latter case, toxicology imposed severe constraints on the

kinds of chemical additives which might be used. Costs also limited dose rates.

Another factor to be considered In any solution was that the rheological

characteristics of the thickened suspension had to allow for convenient handling

and control of the drying process.

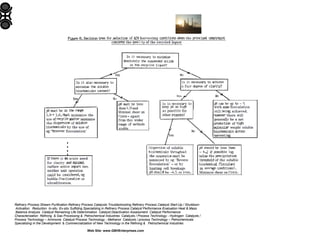

When more detailed work was embarked upon, quite limited studies were

sufficient to indicate that it was unlikely that an “all purpose” floc agent could be

found which would satisfy the various restrictions. The best that could probably

be hoped for was that a natural flocculant (e.g. a gum) could be found which

would be added to retrieve the situation when the ‘normal” flocculation

mechanism broke down.

Costs, however, seemed likely to be prohibitive if continuous dosing were

applied. Accordingly, study was concentrated on optimization of flocculation by

the method of cell lysis (generally by heat shock) followed by pH adjustment to

cause aggregation of the cells, cell fragments and released biopolymers. In the

first stage of “coarse grained” testing studies were made of the flocculation

mechanism, and of the floc and thickened suspension properties using simple,

and now familiar, tools such as optical microscopy and shear modulus

measurements.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com](https://image.slidesharecdn.com/processsynthesis-140128170000-phpapp02/85/Process-Synthesis-7-320.jpg)