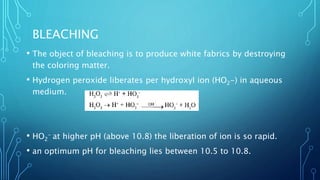

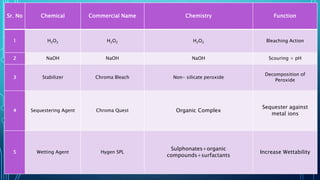

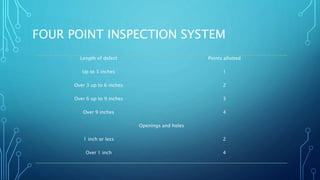

This training presentation covers the key steps in textile processing, including pre-treatment, singeing, desizing, scouring, bleaching, mercerization, dyeing, printing, and finishing. It provides details on the chemicals, parameters, and recipes used for each step. It also discusses quality control procedures like fabric testing, dye lab processes, production planning and control, and grey inspection systems. The goal is to improve fabric properties and ensure quality throughout processing.