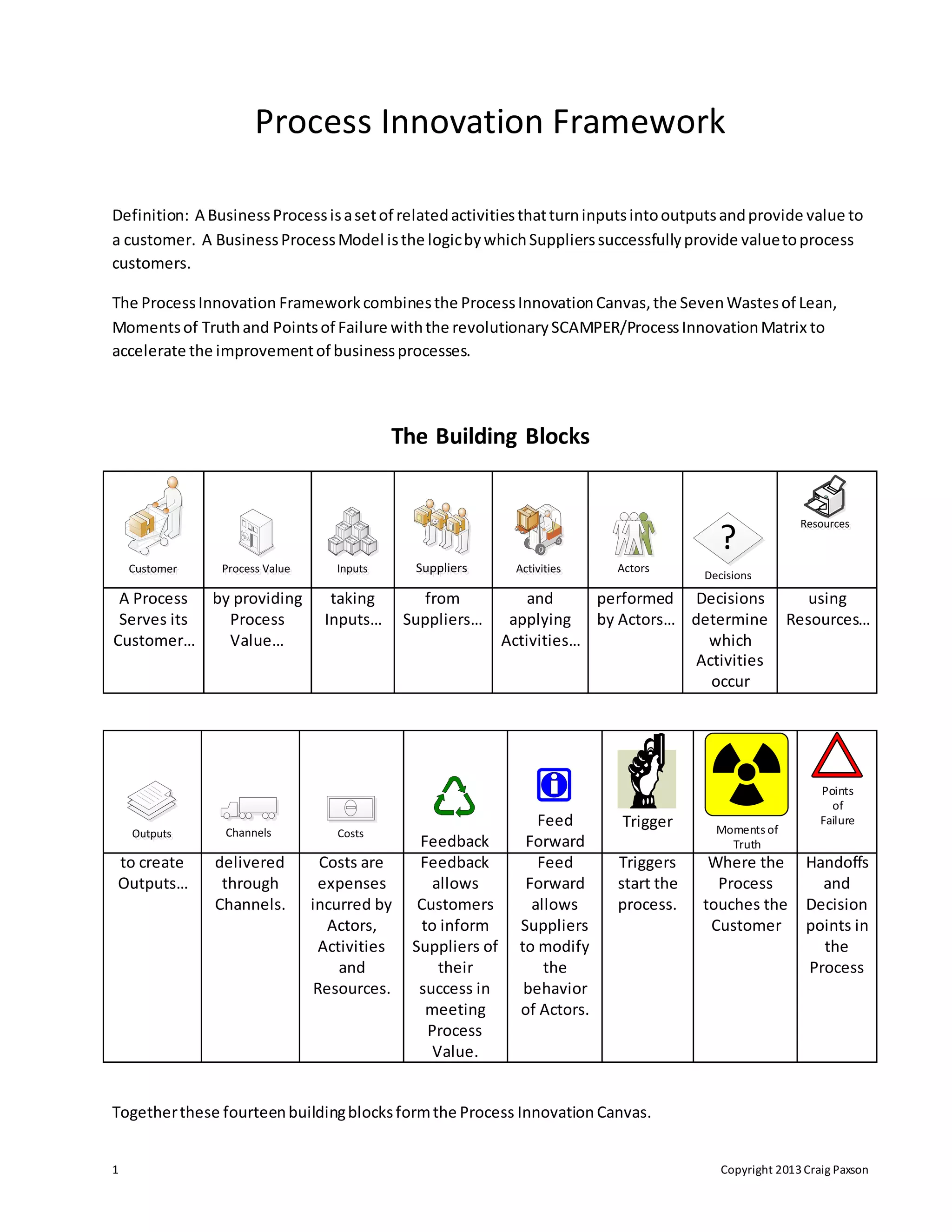

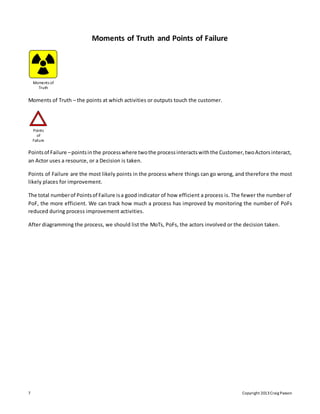

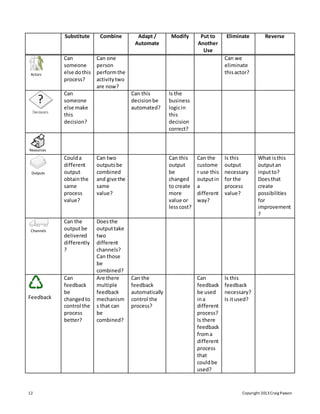

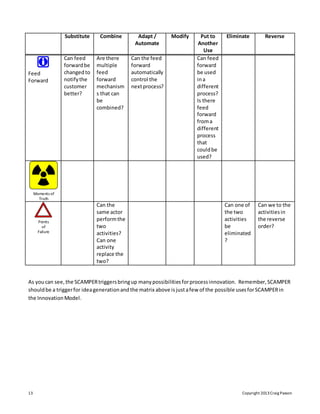

The document outlines a process innovation framework that integrates various methodologies to enhance business processes by focusing on inputs, outputs, customers, resources, and activities. It emphasizes the importance of understanding process value, identifying waste, and using tools like the SCAMPER matrix to stimulate innovation. Additionally, the framework addresses how to deal with customer feedback, moments of truth, and points of failure within processes to drive continuous improvement.