Weaving in Fabric Manufacturing: From Tradition to Innovation

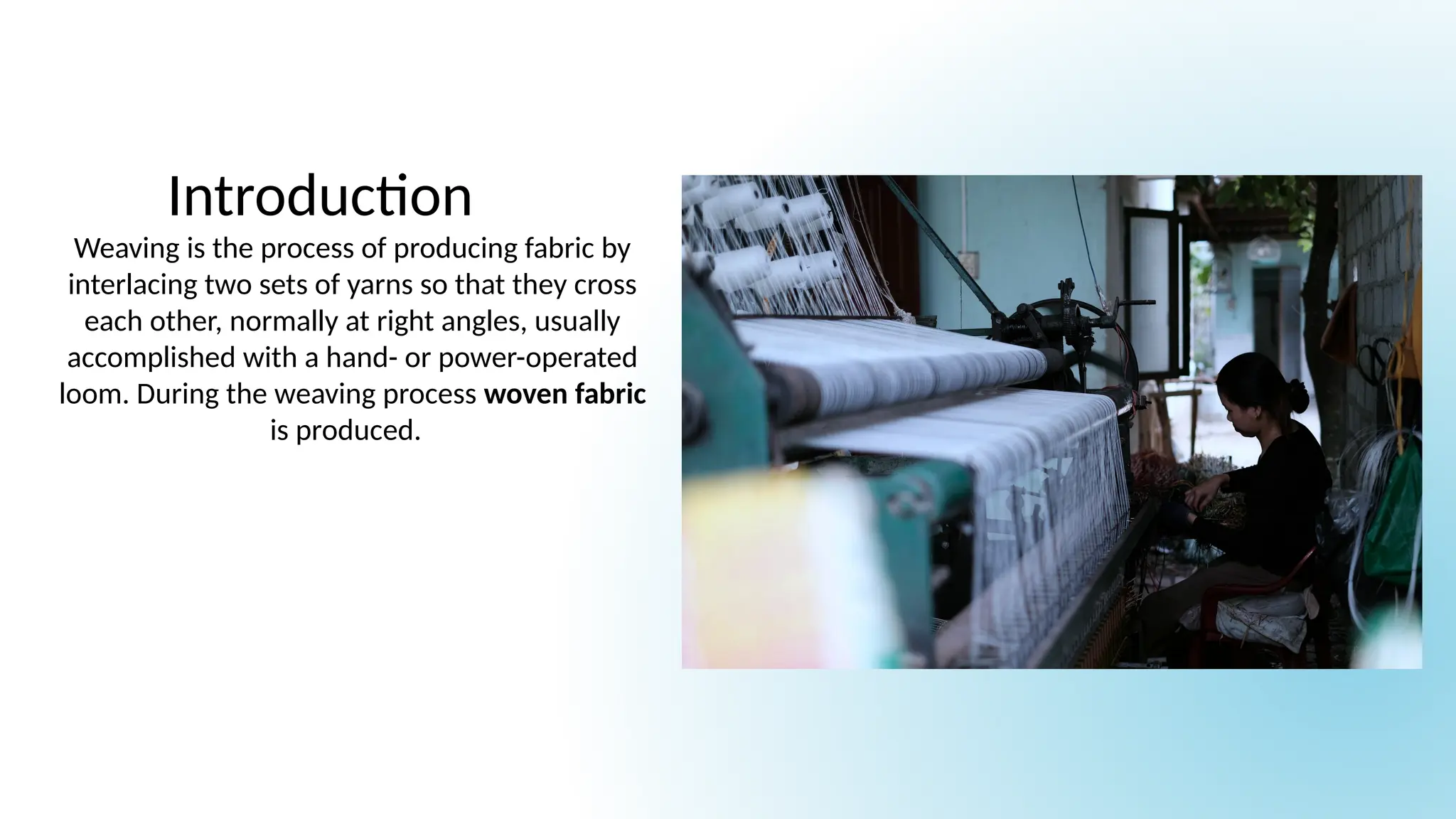

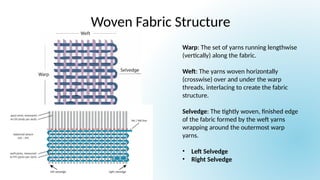

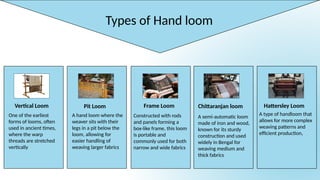

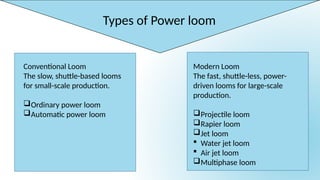

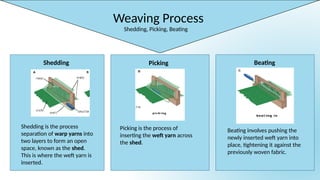

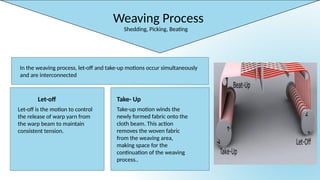

This presentation explores the art and science of weaving, a cornerstone of textile production. It covers the historical journey of weaving, from its origins in ancient Egypt and China to its evolution during the Industrial Revolution. Key topics include the structure of woven fabrics, types of looms (hand and power looms), and the weaving process involving shedding, picking, beating, let-off, and take-up.

The presentation also highlights innovations like shuttle-less weaving and automated threading, showcasing advancements in fabric quality and production efficiency. Applications of woven fabrics in apparel, home furnishings, medical textiles, and industrial uses are examined alongside their environmental impacts. Sustainability practices such as energy-efficient machinery, recycling, and biodegradable materials are proposed as solutions to reduce ecological challenges.