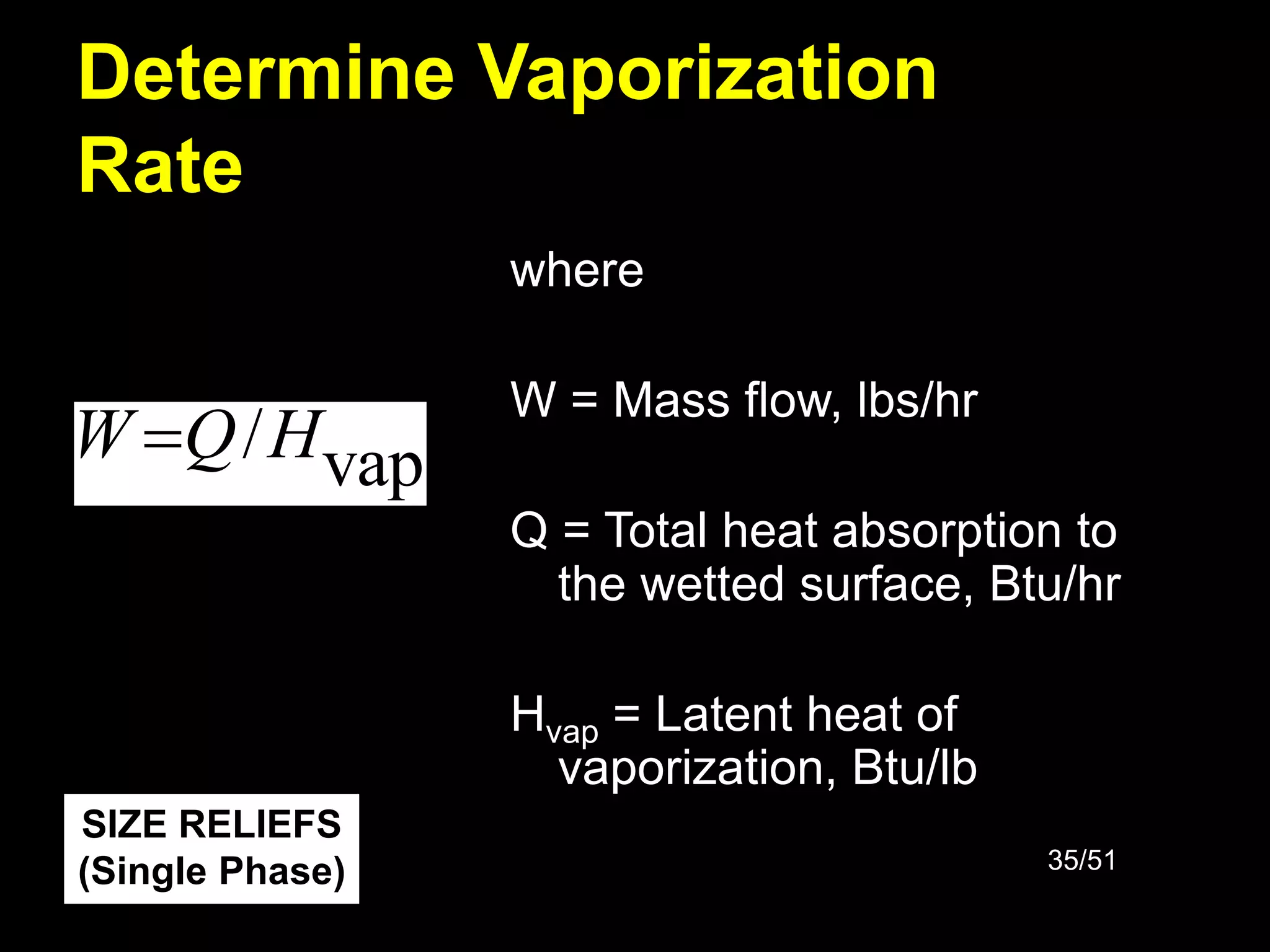

This document discusses pressure relief systems. It begins by defining pressure relief events and overpressure hazards. It then outlines potential lines of defense like inherently safe design, passive control, and installing relief systems. The document goes on to define relief systems and explain why they are used. It provides terminology and code requirements related to relief systems. The bulk of the document is focused on the methodology for designing relief systems, including locating reliefs, choosing device types, developing scenarios, sizing reliefs through calculations, choosing a worst case, and designing the full relief system. It emphasizes the importance of proper installation, inspection, and maintenance of relief systems.