Relief System Design Agenda - Seminar Outline

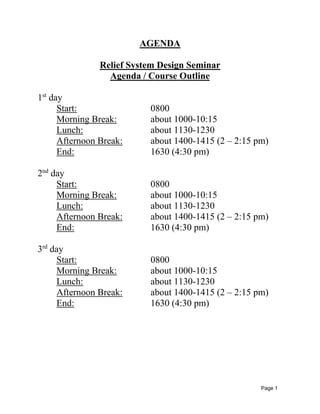

- 1. Page 1 AGENDA Relief System Design Seminar Agenda / Course Outline 1st day Start: 0800 Morning Break: about 1000-10:15 Lunch: about 1130-1230 Afternoon Break: about 1400-1415 (2 – 2:15 pm) End: 1630 (4:30 pm) 2nd day Start: 0800 Morning Break: about 1000-10:15 Lunch: about 1130-1230 Afternoon Break: about 1400-1415 (2 – 2:15 pm) End: 1630 (4:30 pm) 3rd day Start: 0800 Morning Break: about 1000-10:15 Lunch: about 1130-1230 Afternoon Break: about 1400-1415 (2 – 2:15 pm) End: 1630 (4:30 pm)

- 2. Page 2 PRESSURE RELIEF SYSTEM DESIGN SEMINAR Seminar objectives: 1. Identify and review the most important aspects of relief system design 2. Familiarize relevant code requirements affecting relief system design 3. Evaluate relationship between design, operating, set, and relieving pressures 4. Review and evaluate overpressure scenarios 5. Provide guidelines for calculating relieving requirements 6. Identify appropriate relieving credits 7. Review single phase (gas or liquid) and multi-phase relief discharge pressure relief valve sizing equations 8. Evaluate inlet and outlet piping design considerations and equations for single and multiphase flow • 3-day seminar (participants can attend for specific areas of interest) • Seminar can be extended to 4 days where more advanced topics and worked examples are discussed in depth Instructor: Ed Zamejc EZ Relief Systems Consulting, Inc. edzamejc@ezreliefsystems.com Cell: (832) 373-7445

- 3. Page 3 RELIEF SYSTEM DESIGN COURSE OUTLINE Follows Relief System Design Guide (available separately - not included in seminar) Day 1 1. OVERVIEW OF RELIEF SYSTEM DESIGN A. Pressure Relief System Design B. Types of Pressure Relief Devices C. Documentation Requirements D. Industry Loss Experience Related to Pressure Relief Systems E. Codes and Standards Related to Pressure Relief Systems (e.g., OSHA, ASME, API, NFPA) 2. SETTING PRESSURE LEVELS A. Definitions B. Pressure Relief Device Set Pressures (Code Requirements) C. Allowable Pressures during Relief (Code Requirements) D. Operating Differentials for Pressure Relief Valves E. Rupture Disk Pressure Settings F. Temperature Effects on Opening Pressure G. Vessel Design Pressure versus MAWP 3. OVERPRESSURE SCENARIO SELECTION A. Introduction B. Scenario Selection Guidelines C. Information Needs D. Scenario Development Process E. Common Mode Failures F. Multiple Contingencies/Likelihood Considerations G. Analysis of 20 Standard Vessel Overpressure Scenarios [Applied to Site-Specific Example If Possible] H. Piping I. Vacuum Causes J. Scenarios Where Relief Devices do not Generally Protect K. Scenarios Where Relief Devices are not Generally Designed L. Car-Seal Open/Chain Lock Open Valves M. Management of Change (Note: Part of Section 3 may need to be covered in Day 2)

- 4. Page 4 Day 2: (Finish Section 3, as required) 4. RELIEF REQUIREMENT DETERMINATION A. Information Needs B. Determining Relief Requirements for 20 Standard Scenarios - General Considerations, Detailed Calculations and Emphasis on Site Specific Cases and: 1. Thermal Expansion 2. Pool Fire Exposure C. Capacity Credits – Allowable and Non-Allowable D. Alternate Relief Path Credits E. Single or Multiphase Relief Considerations 5. PRESSURE RELIEF DEVICE SELECTION (OPERATING CHARACTERISTICS) A. Vents for Low Pressure Service B. Pressure Relief Valves 1. Spring-Loaded (Conventional and Balanced Bellows) 2. Liquid Certified Valves 3. ASME Section I Steam Valve 4. Pilot-Operated Relief Valves C. Rupture Disks D. Rupture Disk/Pressure Relief Valve Combinations E. Buckling Pins F. Maintenance aspects (optional) Day 3: 6. SIZING PRESSURE RELIEF VALVES A. Origin of Sizing Formulas B. Single Phase Flow Device Sizing 1. Gas or Vapor Sizing Critical Flow 2. Gas or Vapor Sizing Sub-Critical Flow 3. Non-flashing Liquid Sizing C. Two-Phase Flow Device Sizing (Omega Method) 1. Two Point Method to Calculate Omega 2. Multiphase Critical Flow Equation 3. Multiphase Sub-Critical Flow Equation 4. Subcooled-Flashing Liquid Sizing D. Relieving of Fluids above Thermodynamic Critical Conditions

- 5. Page 5 7. RELIEF SYSTEM PIPING DESIGN AND CONSIDERATIONS A. Piping Design General Considerations B. Sizing Stand-alone Rupture Disk Relief Systems C. Pressure Relief Valve Inlet Line Sizing 1. Code Requirements 2. Inlet Pressure Drop Equation (all fluid phases) 3. Options for Handling High Inlet Pressure Loss D. Pressure Relief Valve Outlet Line Sizing 1. Conventional Versus Balanced Bellows Valves 2. Incompressible Liquid Line Sizing 3. Compressible Gas (vapor) Line Sizing 4. Two Phase Fluid Line Sizing (Omega Method) E. Piping Layout Considerations 1. Isolation Valves in Relief Systems 2. Relief System Piping Arrangements 3. Brittle Fracture Potential 4. Acoustic-Induced and Turbulence-Induced Fatigue F. Relief Discharge to Atmosphere 1. General Requirements 2. Atmospheric Discharge of Non-Hazardous Materials 3. Flammable and Toxic Discharge from Atmospheric Vents 4. Dispersion and Consequence Modeling 8. REACTIVE SYSTEMS Very brief general discussion 9. RELIEF HEADERS, NETWORKS, AND EFFLUENT HANDLING A. Scenarios B. Methodology C. Knock-out Drums D. Flare Stacks 1. General Guidelines 2. Thermal Radiation 3. Purging E. General Discharge Location Considerations F. Flare Gas Recovery