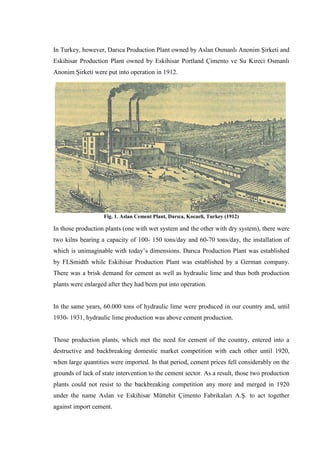

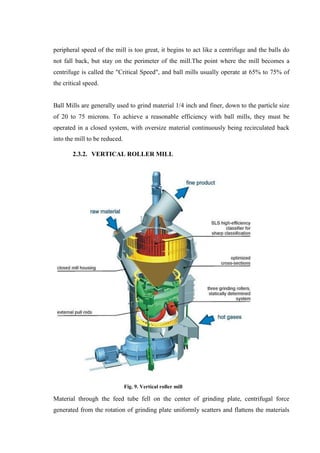

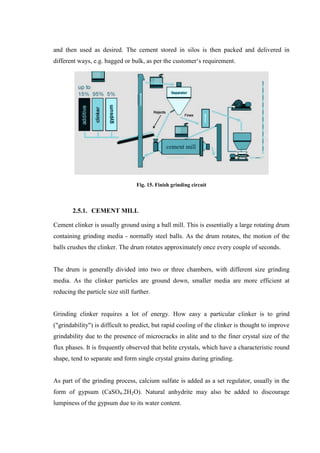

This document provides a history and overview of cement production. It discusses the origins of cement dating back to ancient civilizations using lime as a binding agent. Modern cement originated in the 18th-19th centuries as individuals experimented with combinations of limestone and other materials. The first commercial cement plant opened in England in 1848. Cement production began in Turkey in 1912 with two initial plants. The document then focuses on Göltaş Göller Bölgesi Çimento Sanayi ve Ticaret Anonim Şirketi, the first private cement factory in Turkey, which opened in 1969 and details its production facilities, products, and manufacturing process.