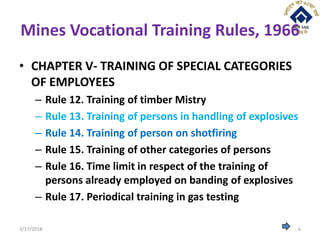

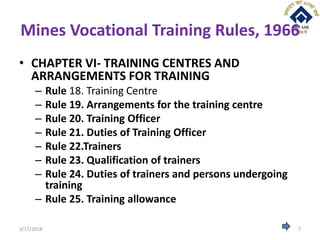

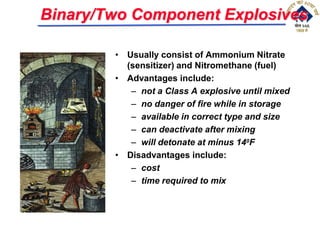

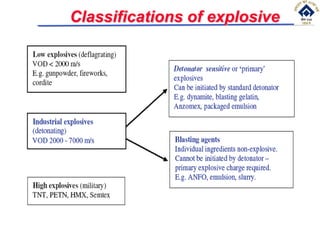

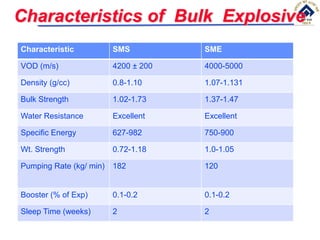

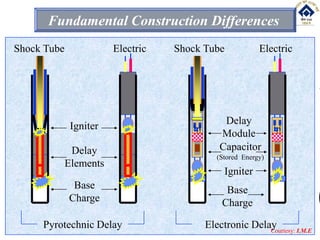

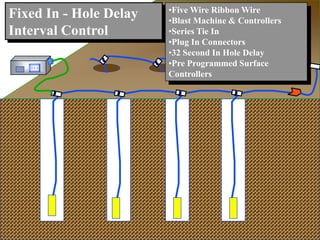

The document provides information about an upcoming training program on explosives and safety taking place on March 10, 2018. It discusses the aims and objectives of the program, which are to train persons who handle explosives on transportation, loading, and other blasting activities. It outlines the program structure and sessions to be covered by different faculty members, including legislation and requirements, explosives properties, transportation, inspection roles, and operations. The concluding sections provide a program folder and thank participants for attending.