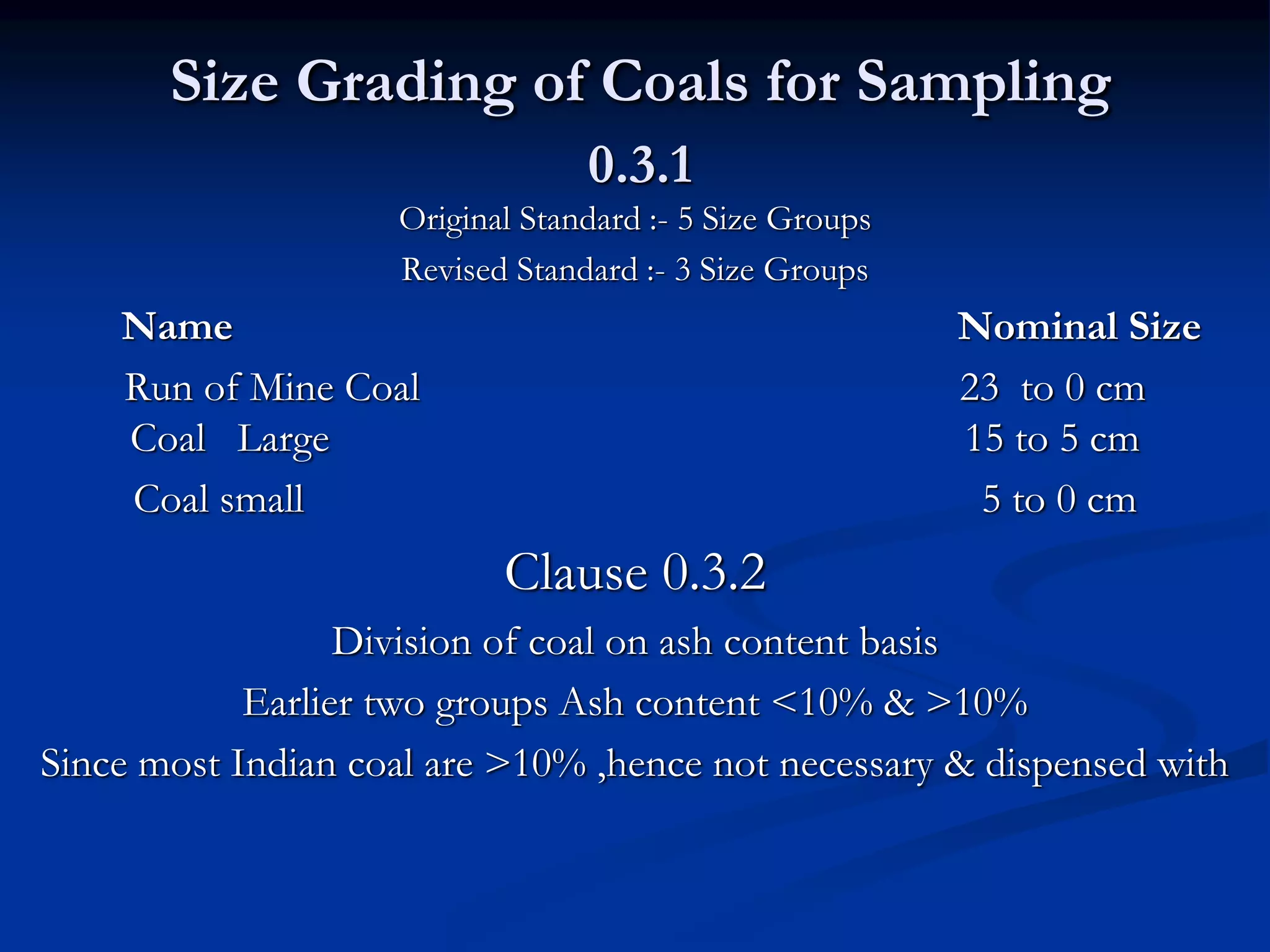

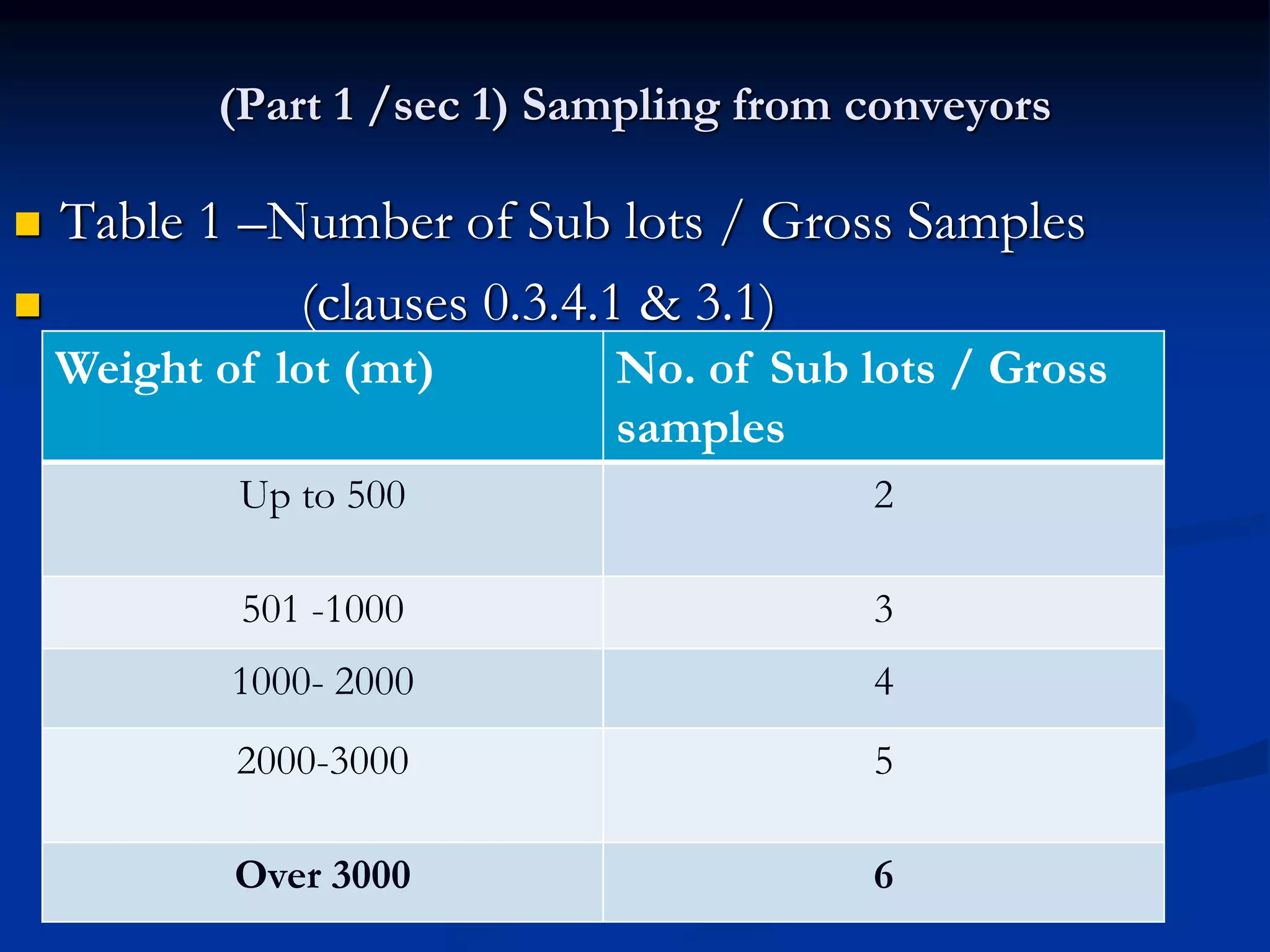

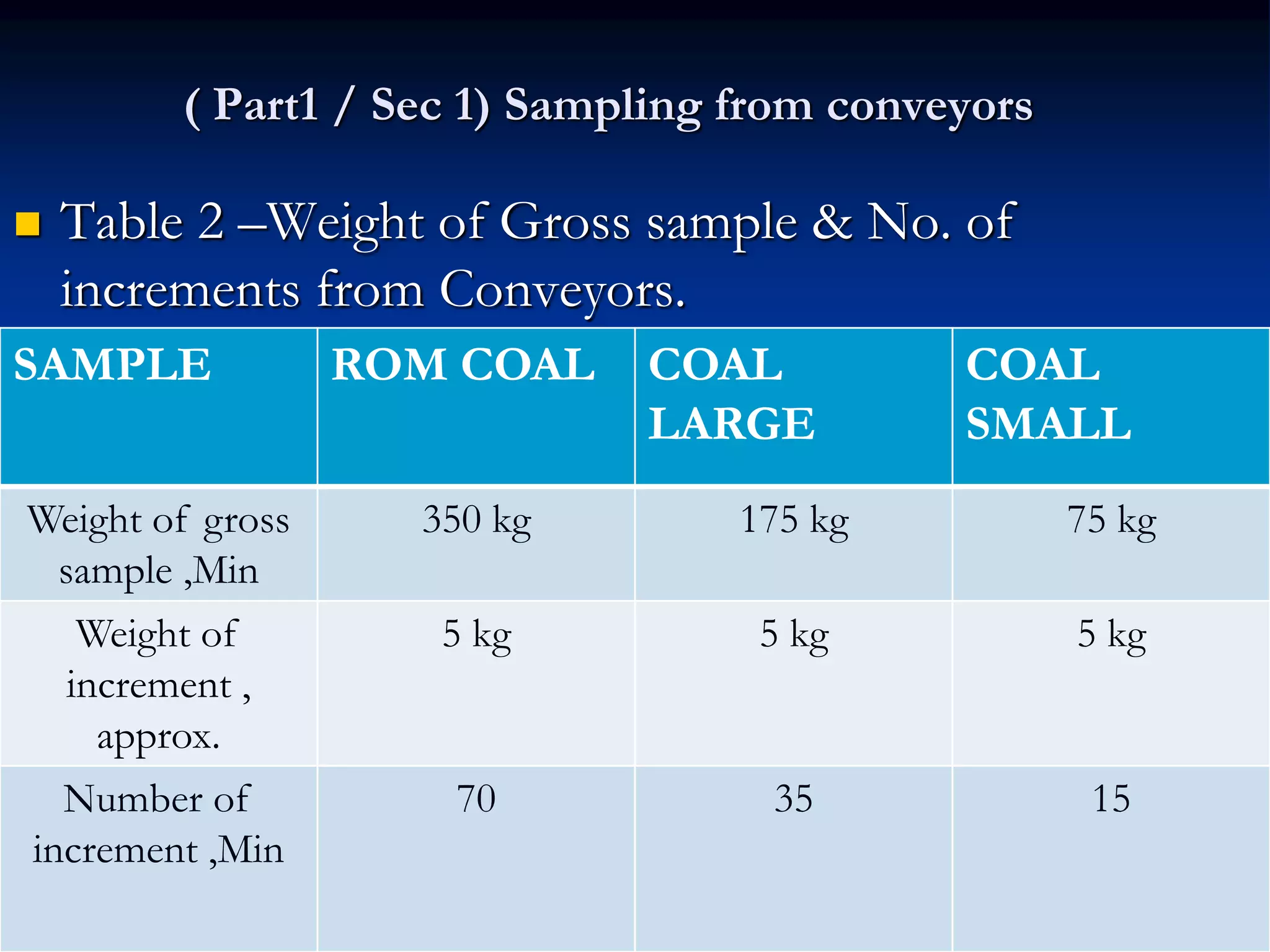

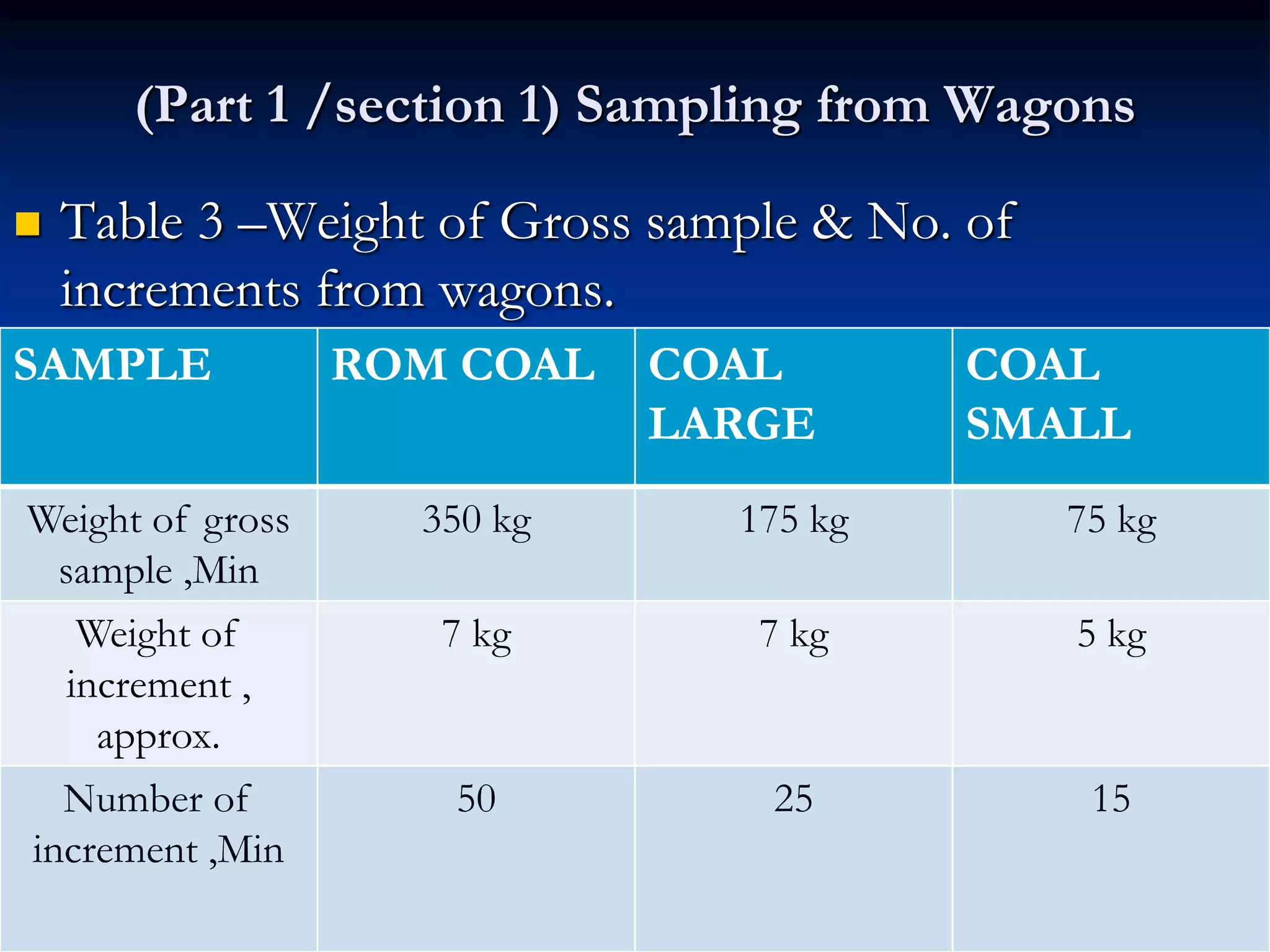

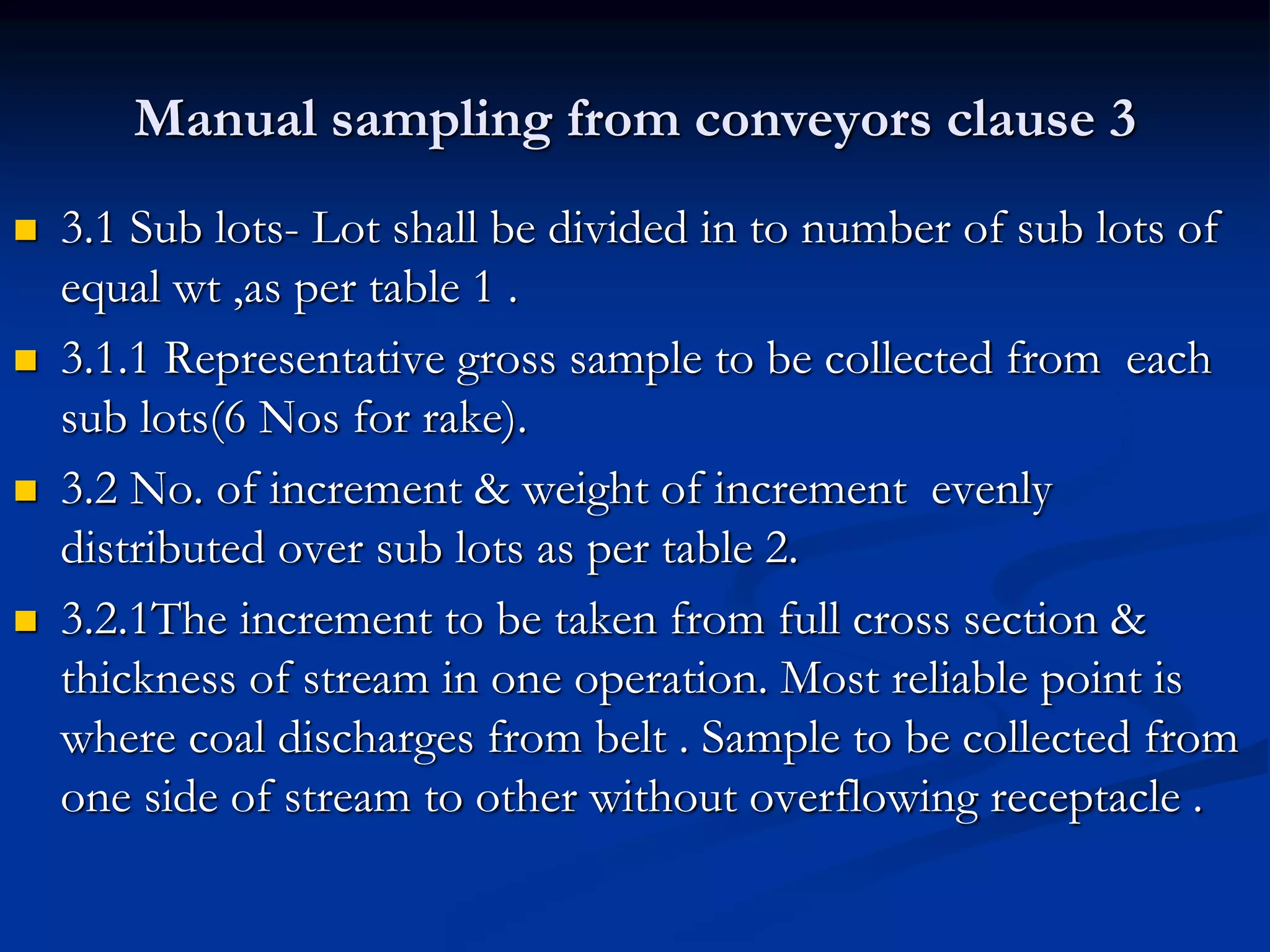

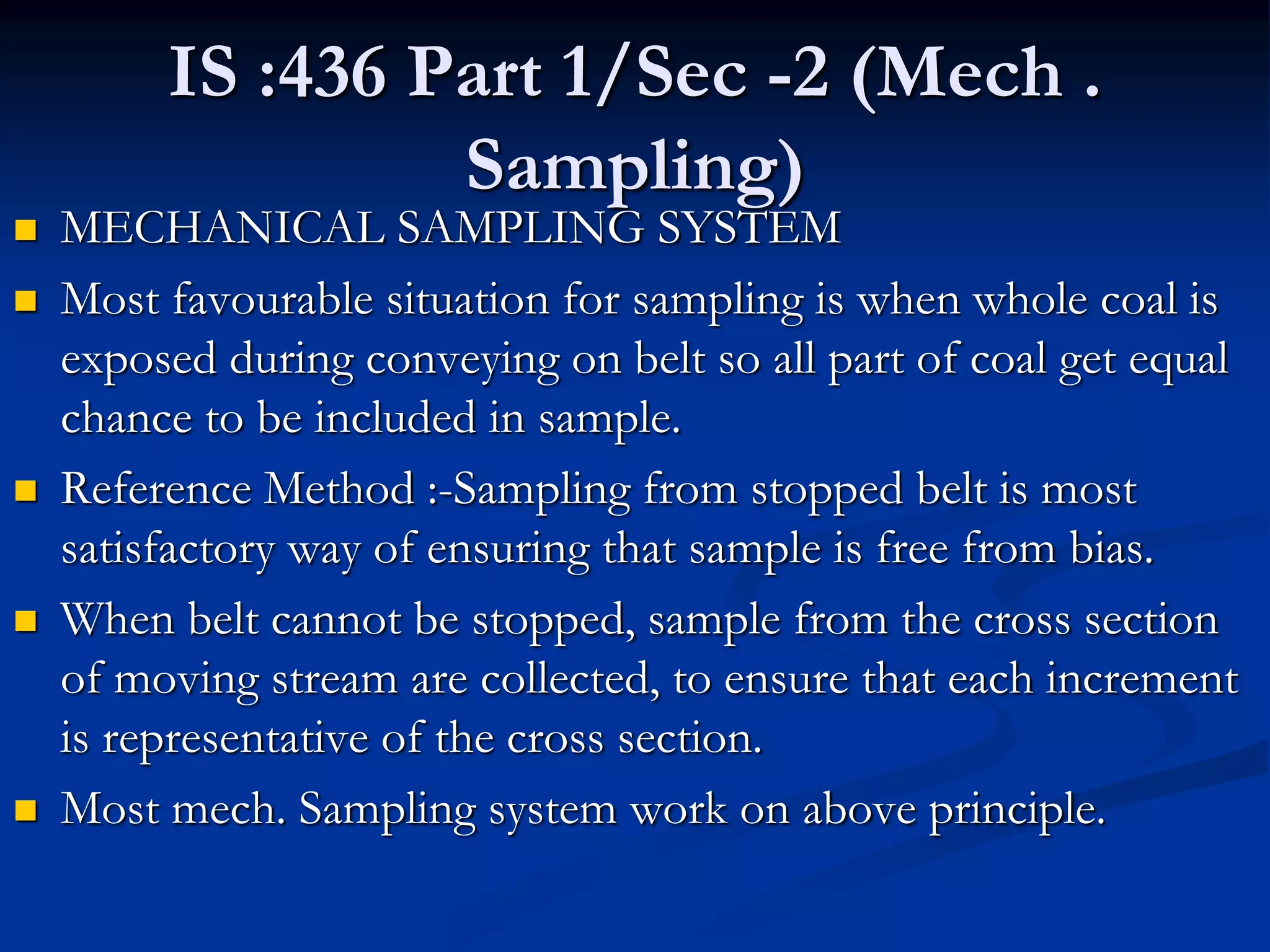

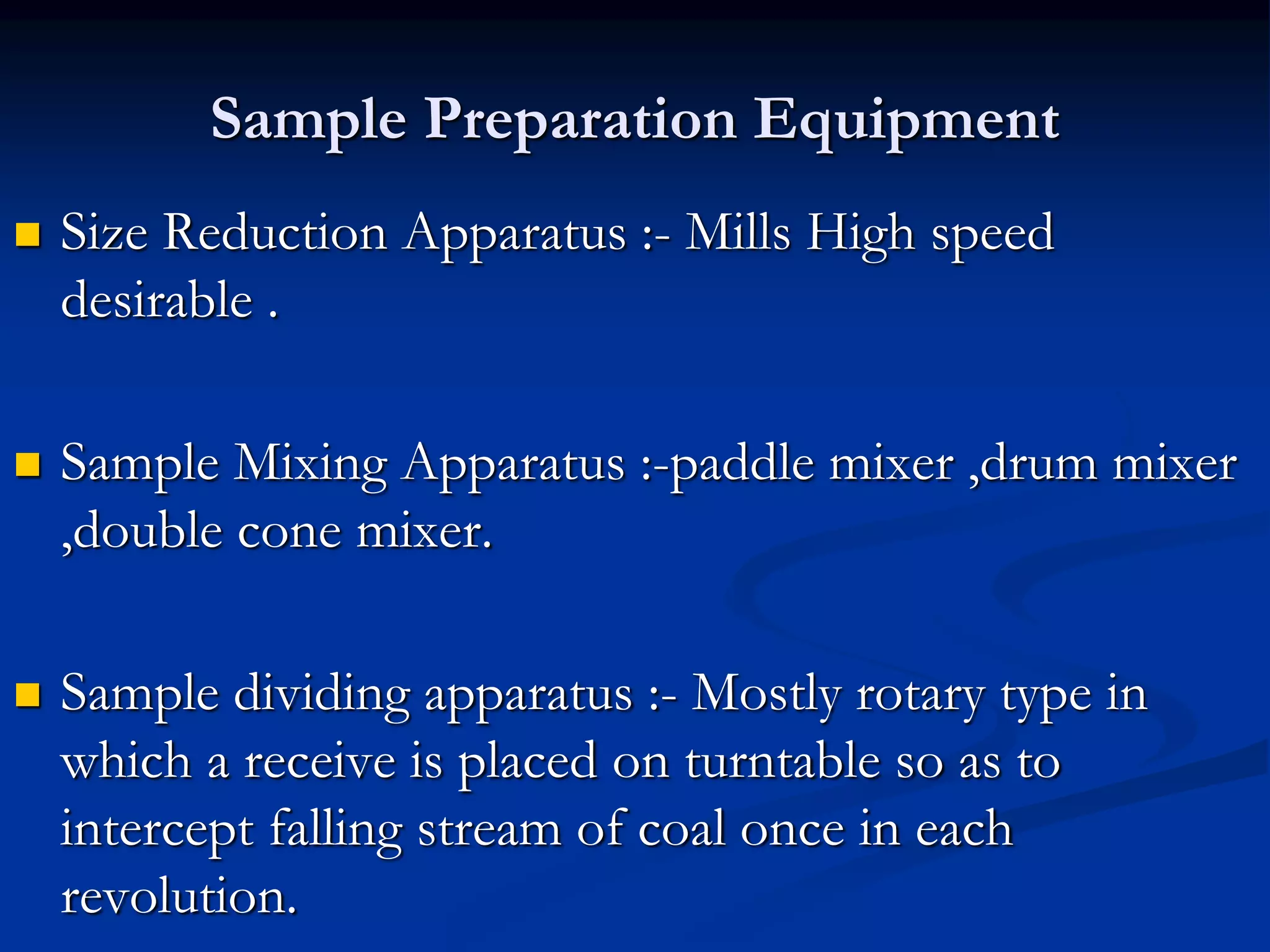

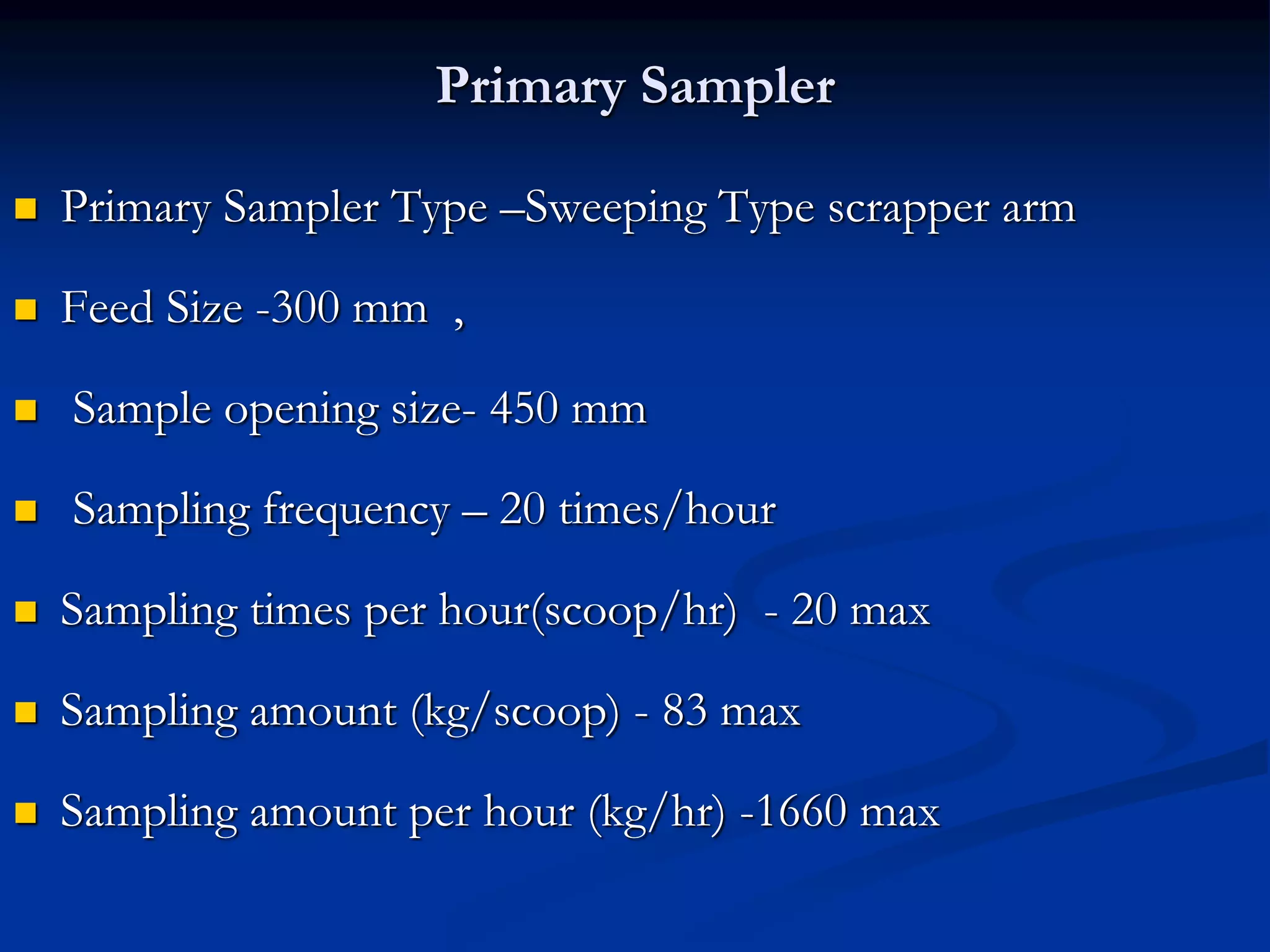

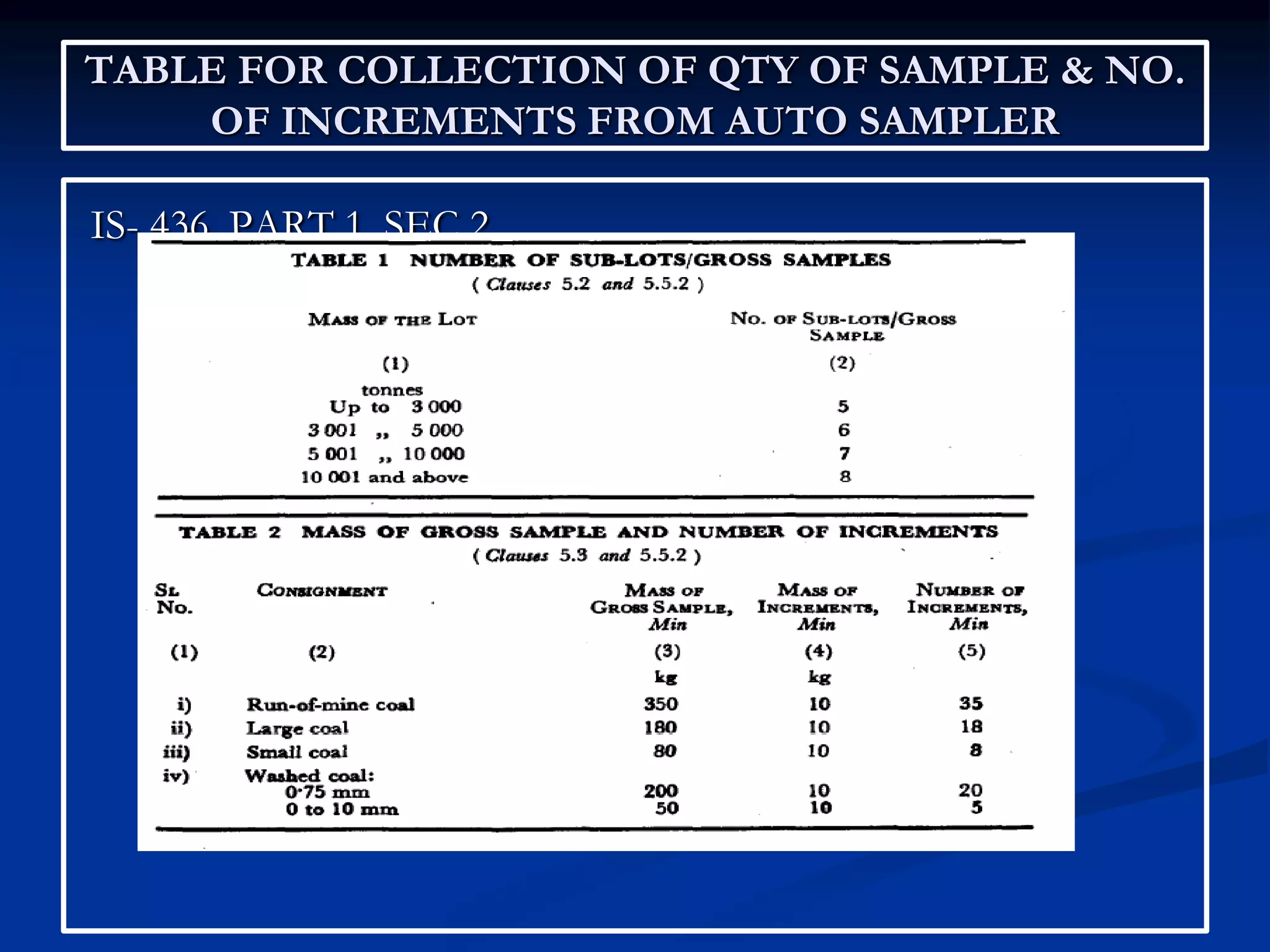

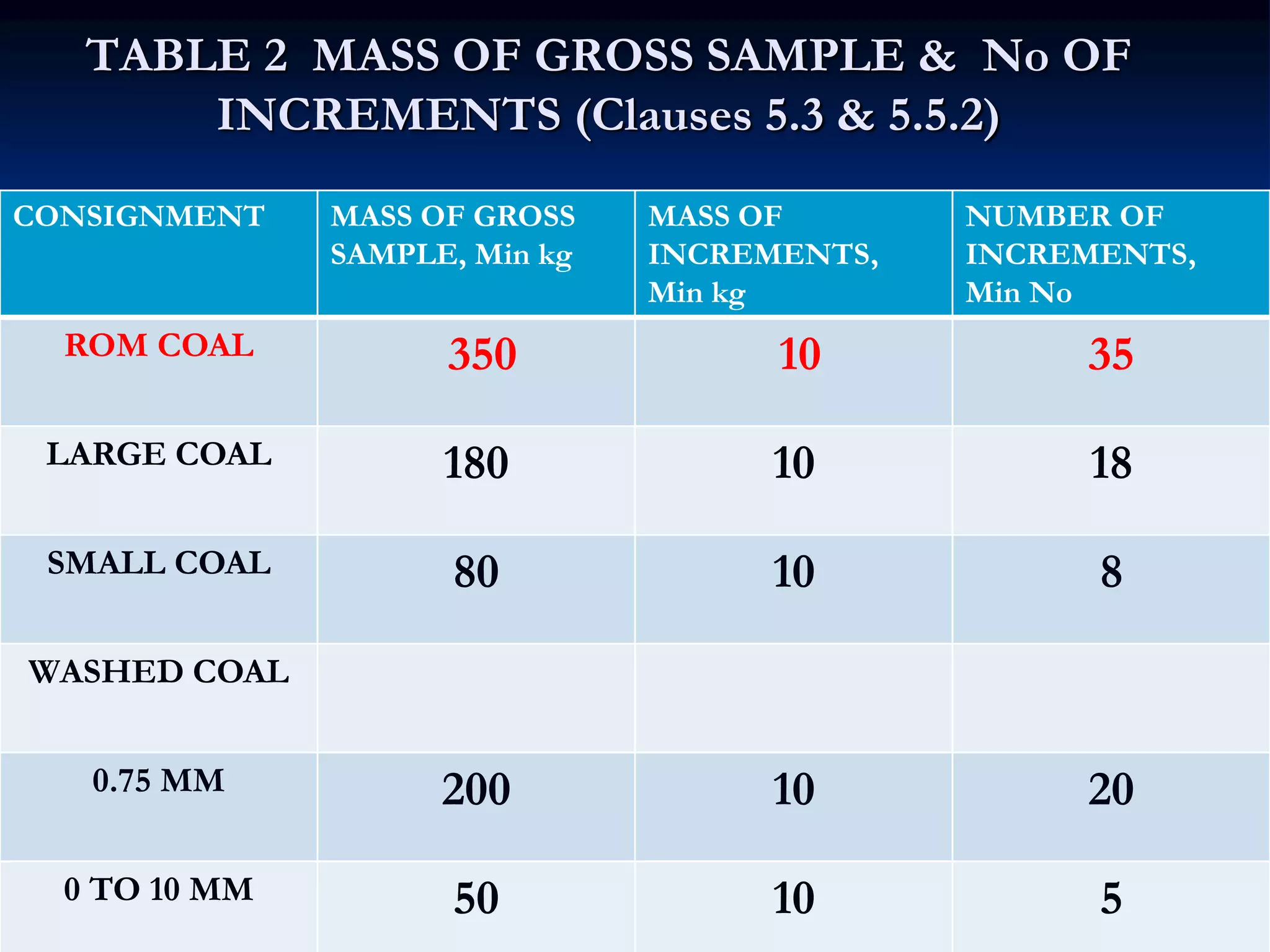

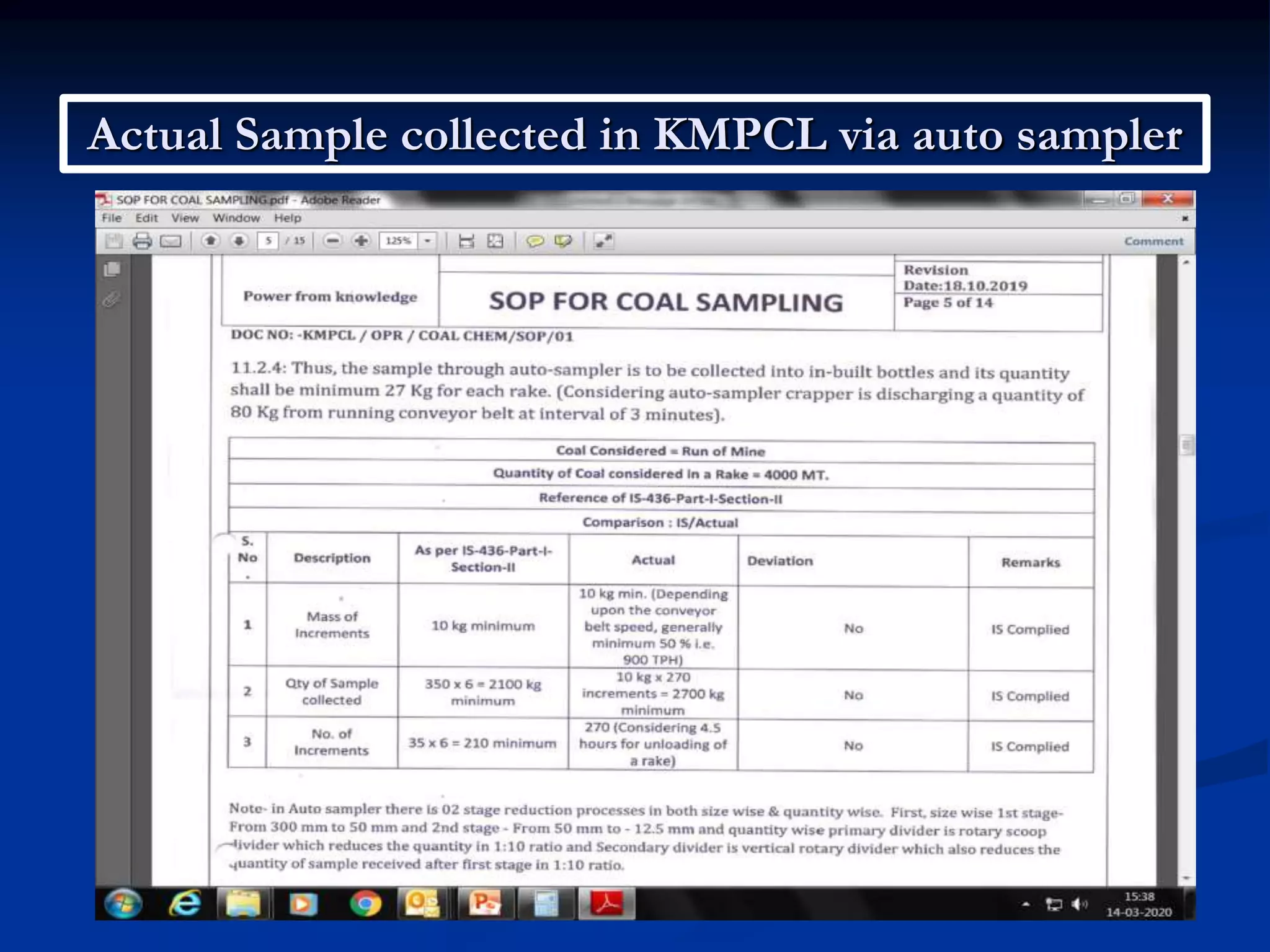

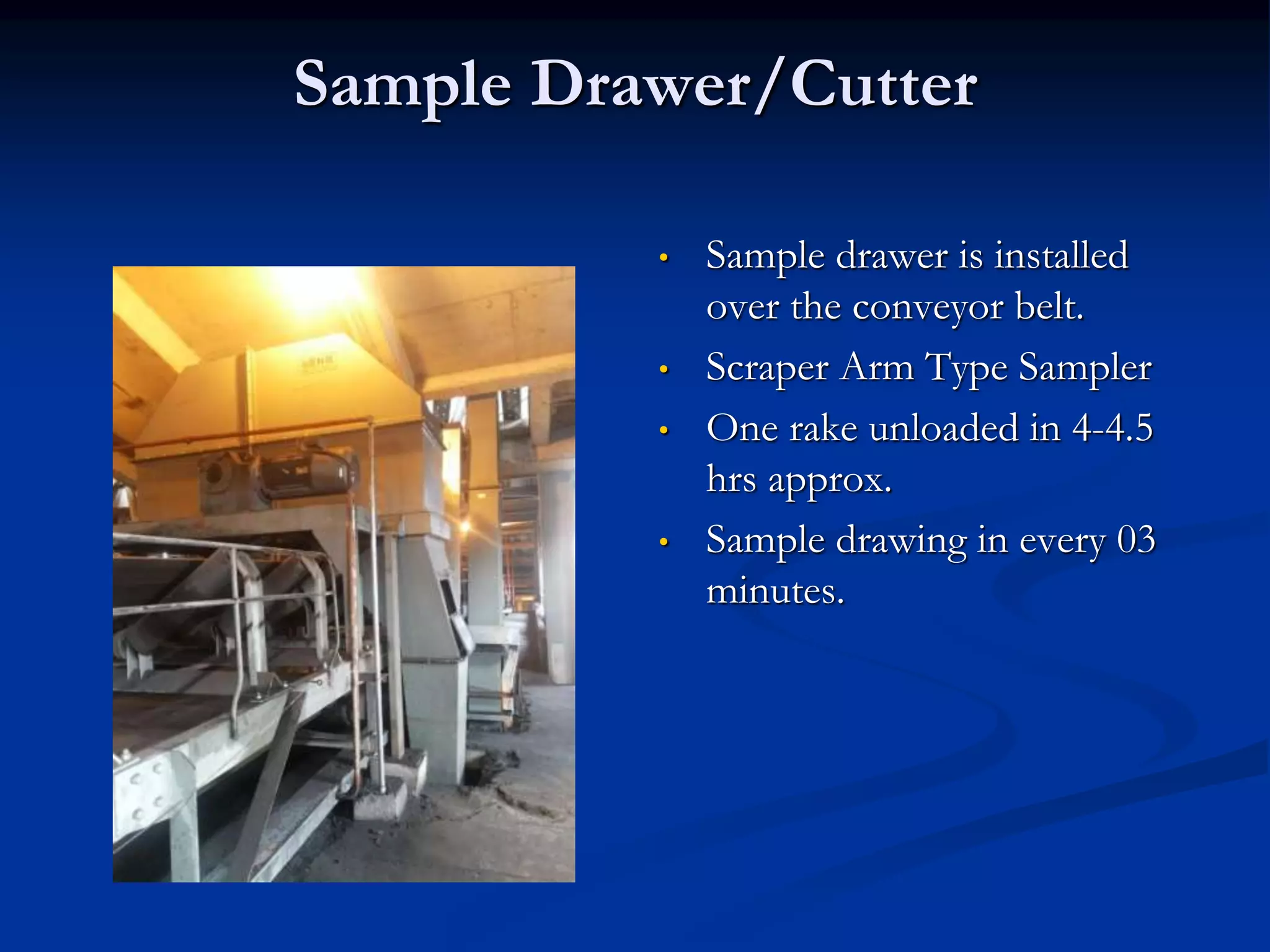

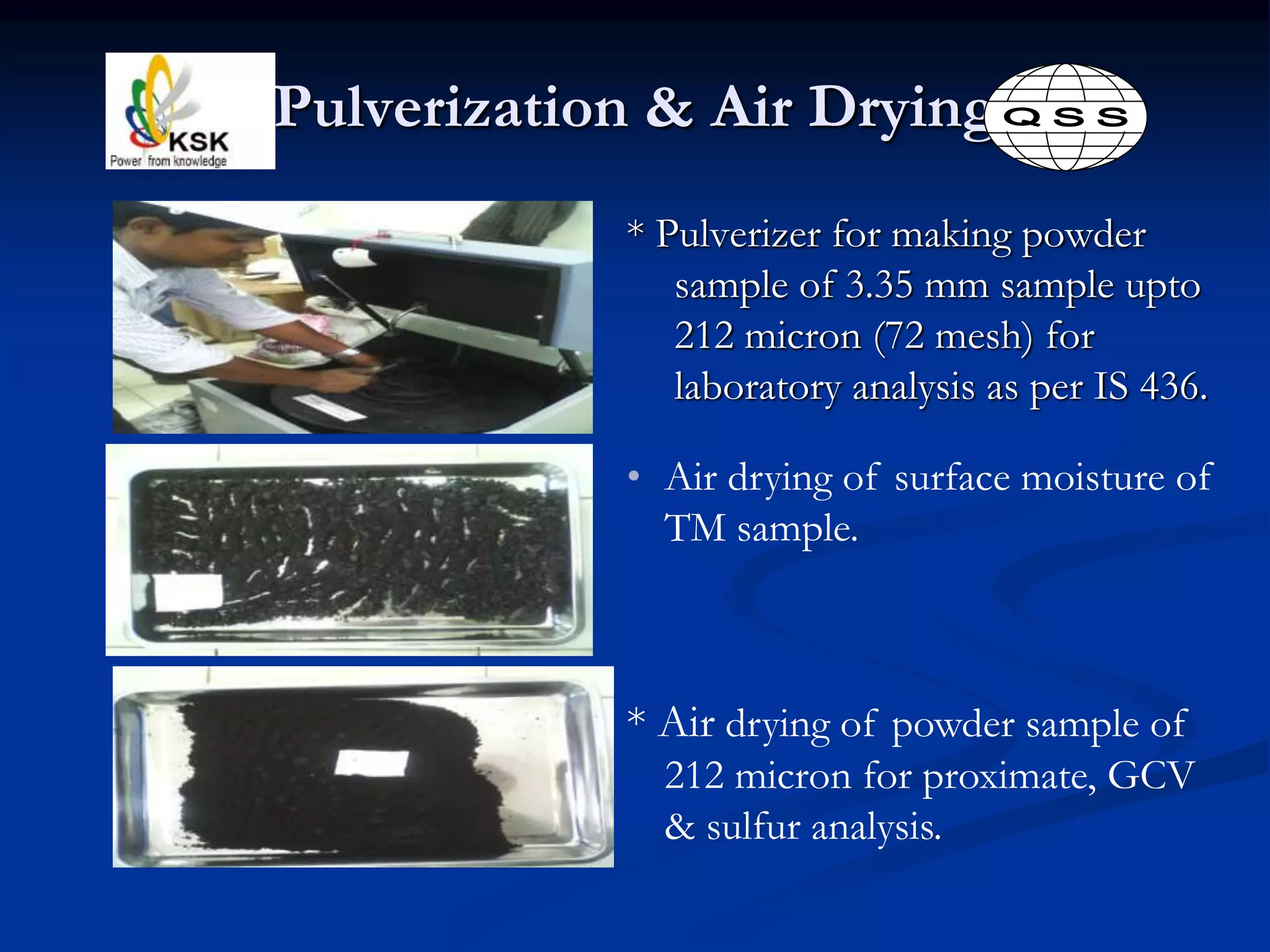

The document outlines the standards and procedures for coal sampling and preparation as per IS 436-1964, detailing both manual and mechanical sampling methods. It includes specifications for size grading, sample collection from moving conveyors, and the importance of systematic sampling practices to ensure representativeness and accuracy. Various tables and clauses provide guidelines on the number of sub-lots, gross sample weights, and increment sizes necessary for reliable testing and analysis of coal quality.