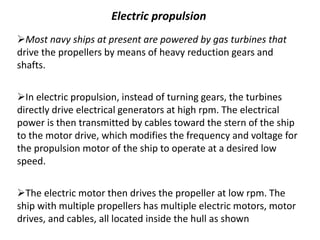

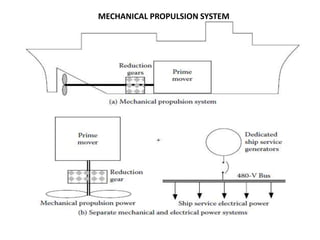

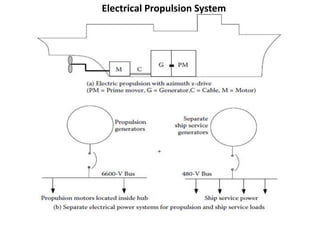

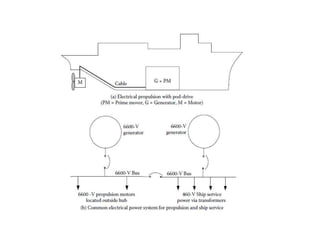

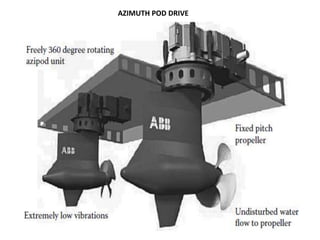

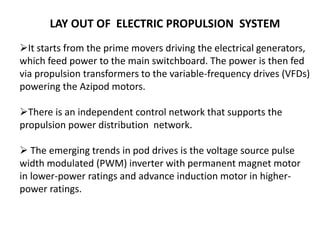

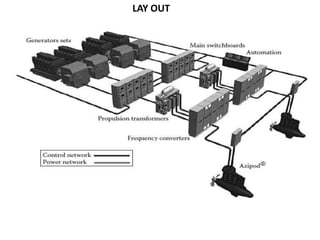

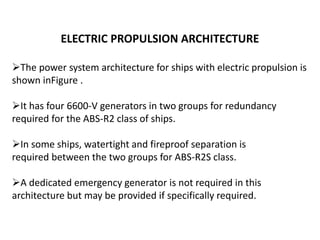

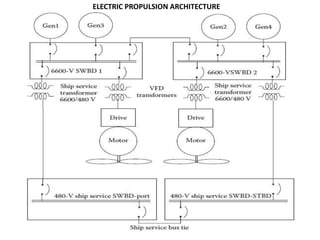

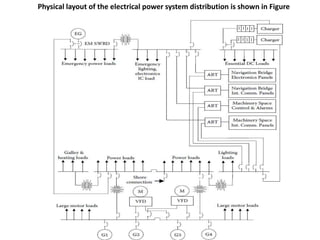

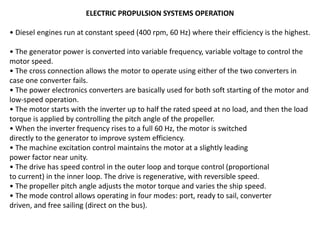

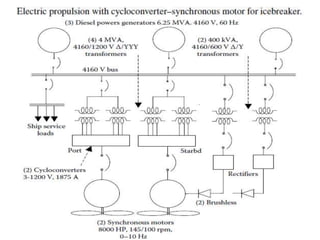

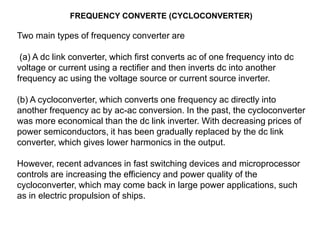

Electric propulsion uses variable frequency drives to convert fixed line frequency power to variable frequency power that can match the required propeller speed during different ship operations. It offers quieter operation and maximizes usable space. Common systems include gas turbines powering generators that power synchronous or induction motors. The U.S. Navy is committed to electric propulsion. Key advantages include redundancy if cables are damaged instead of drive shafts, and flexibility in ship component placement. Azimuth pod drives locate propellers in pods that can rotate 360 degrees for maneuverability without rudders or steering gear. This saves space versus long drive shafts.