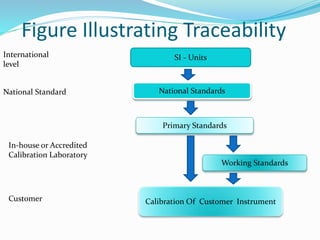

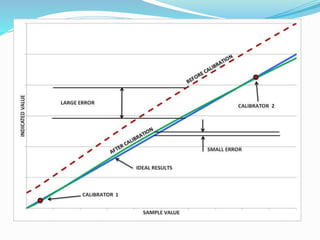

Caltech Private Limited held a meeting to discuss calibration. They explained that calibration verifies the accuracy of instruments by comparing them to standard references. It is important to calibrate regularly to avoid false test results. The benefits of calibration include ensuring accuracy, minimizing breakdowns, and meeting certification requirements. Calibration is also important for quality improvement, safety, and interrelating quality and productivity. Caltech recommends on-site calibration for pharmaceuticals. They provide quality calibration services with accredited equipment and traceable standards.