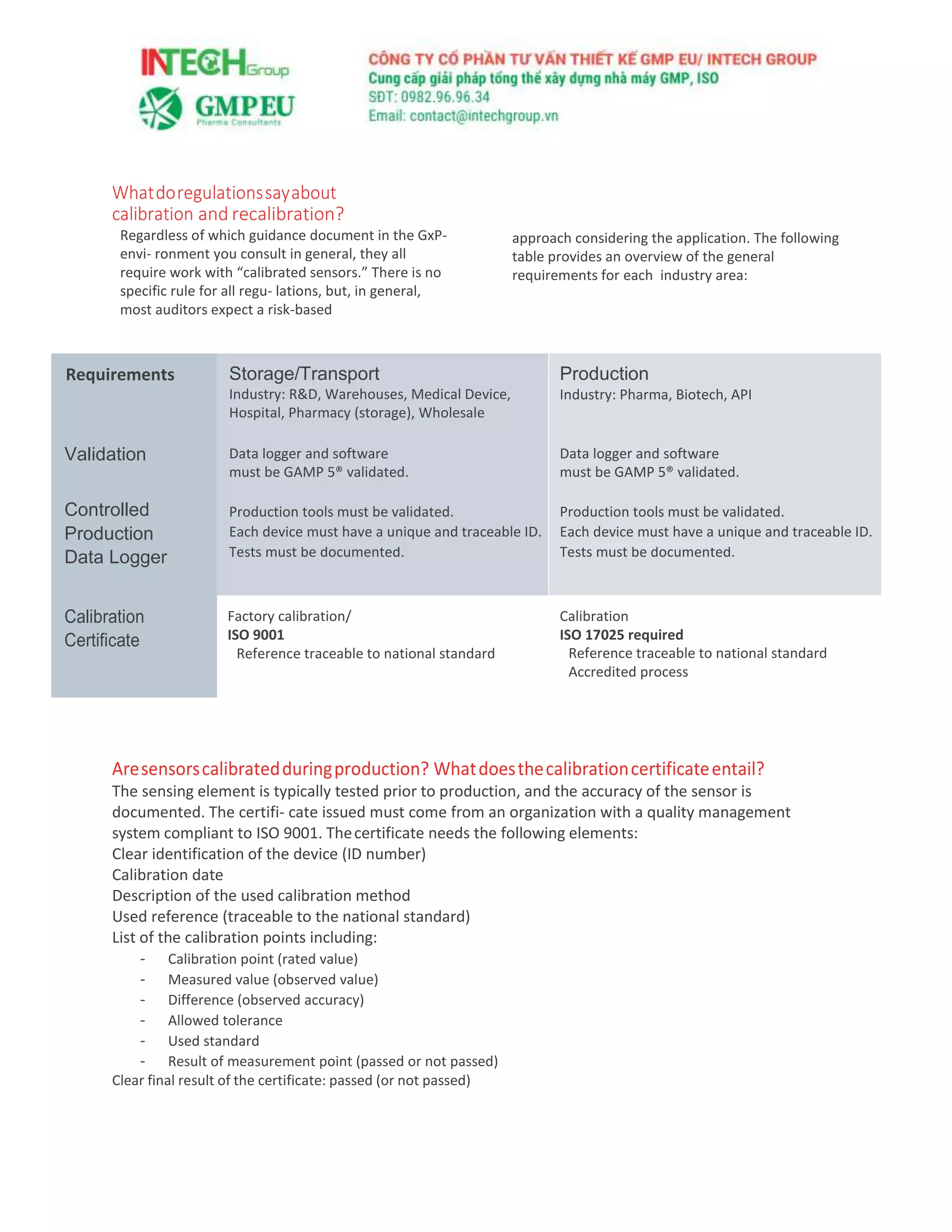

This document provides a comprehensive guide on the calibration of temperature sensors in compliance with GxP regulations, emphasizing the importance of using calibrated sensors for handling temperature-sensitive materials. It outlines the calibration process, requirements for calibration certificates, and considerations for recalibration based on risk assessment. Additionally, it details the differences between standard and ISO 17025 calibration processes, highlighting the necessary elements included in the calibration documentation.