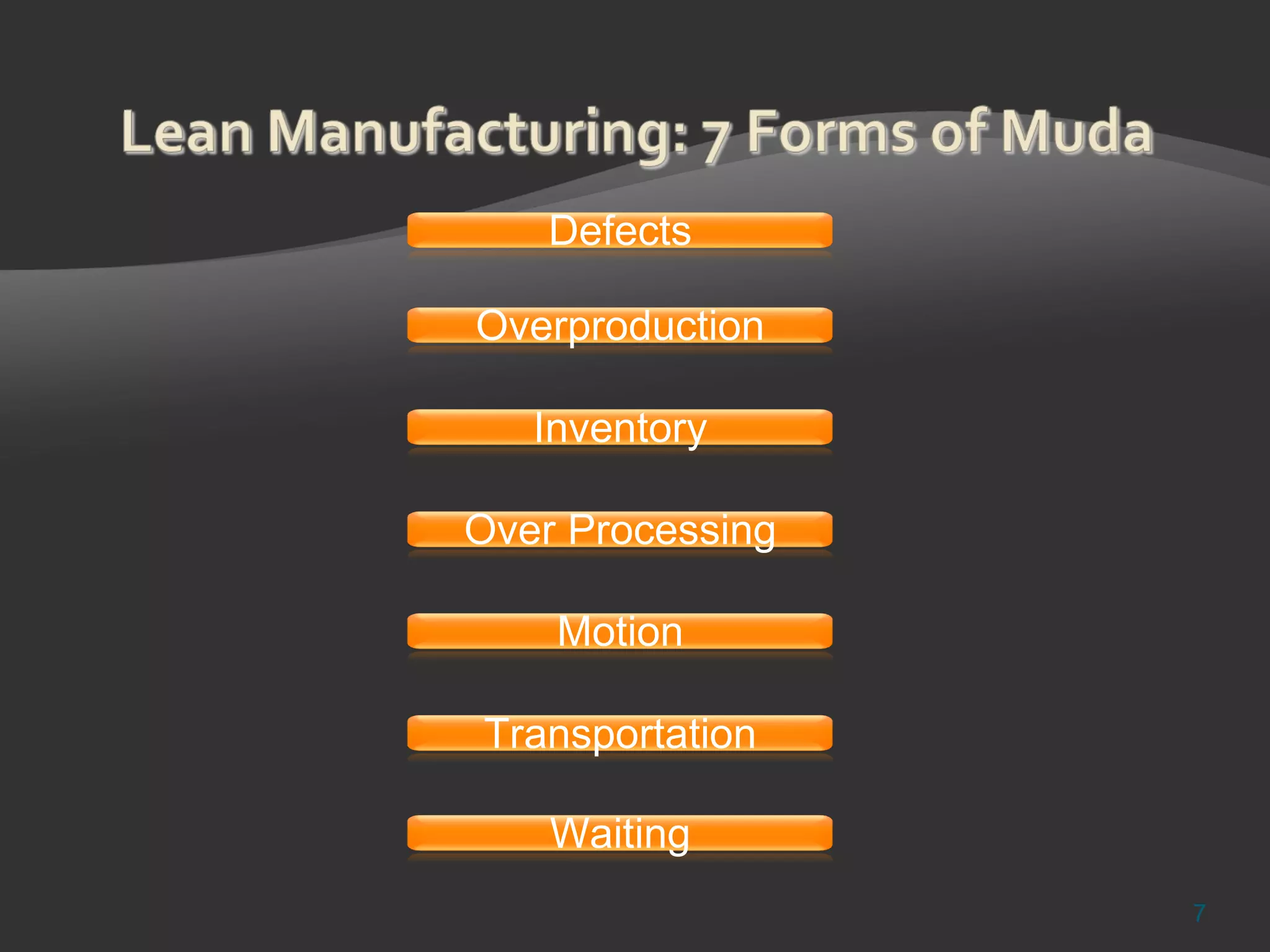

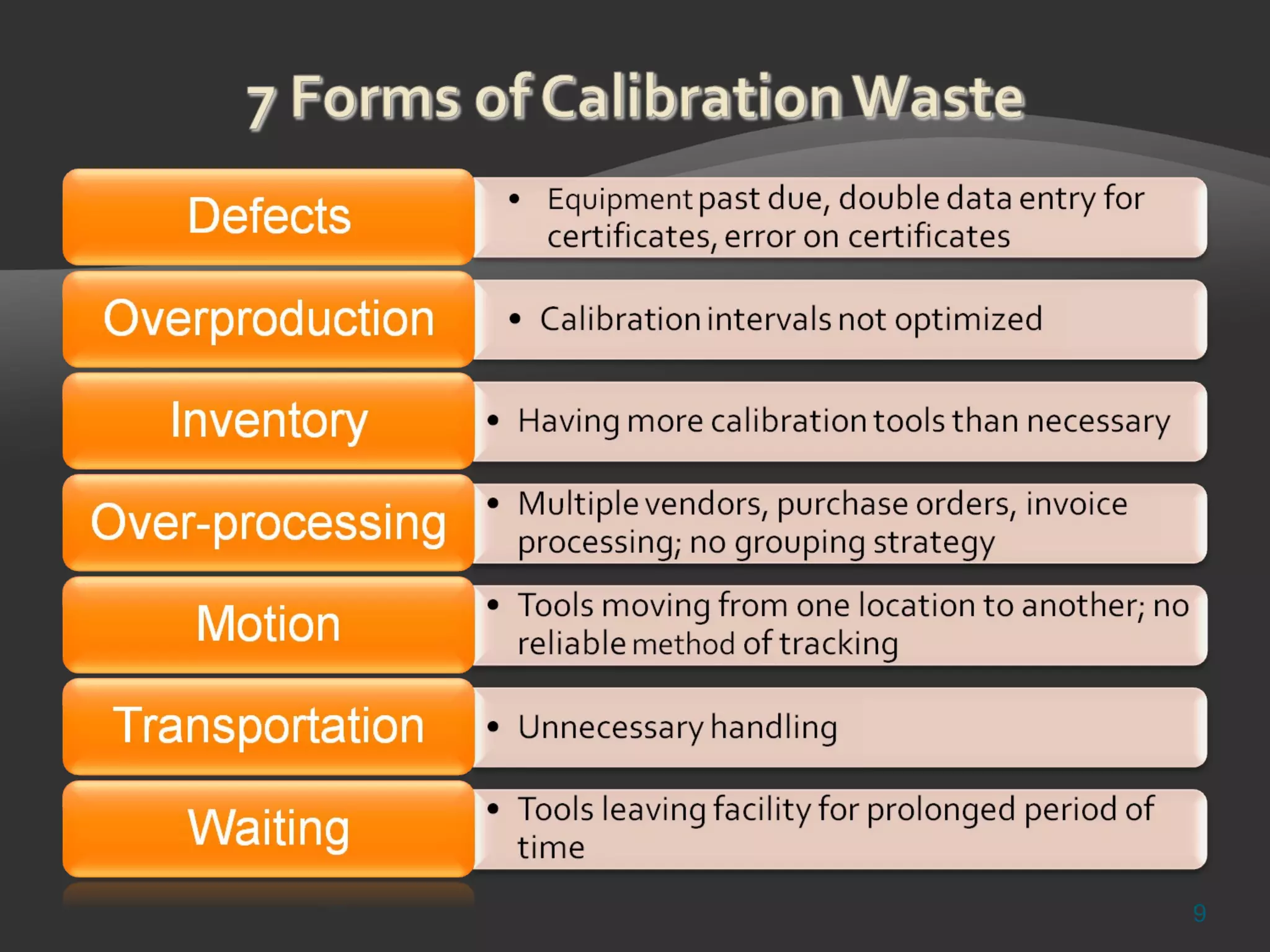

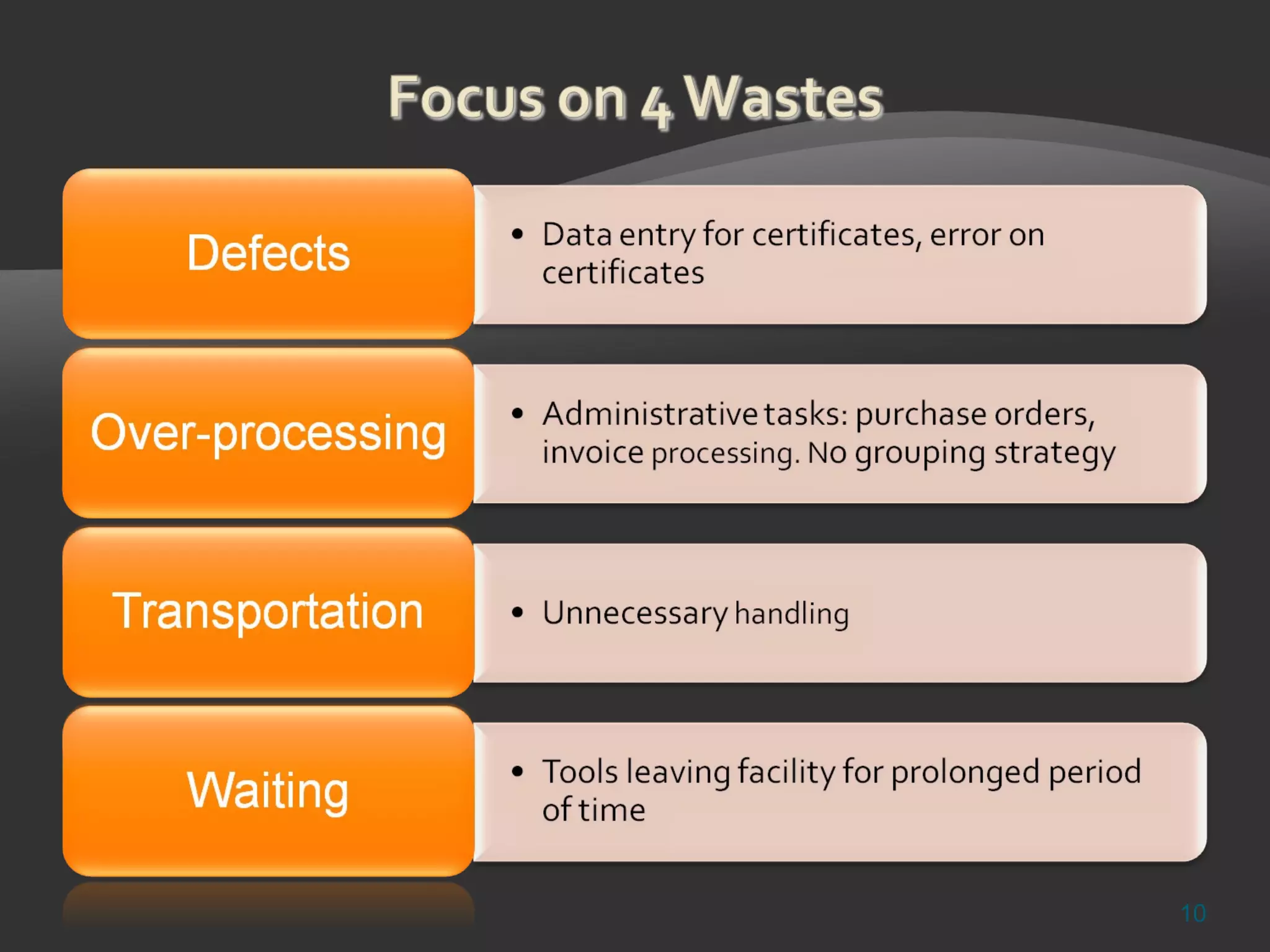

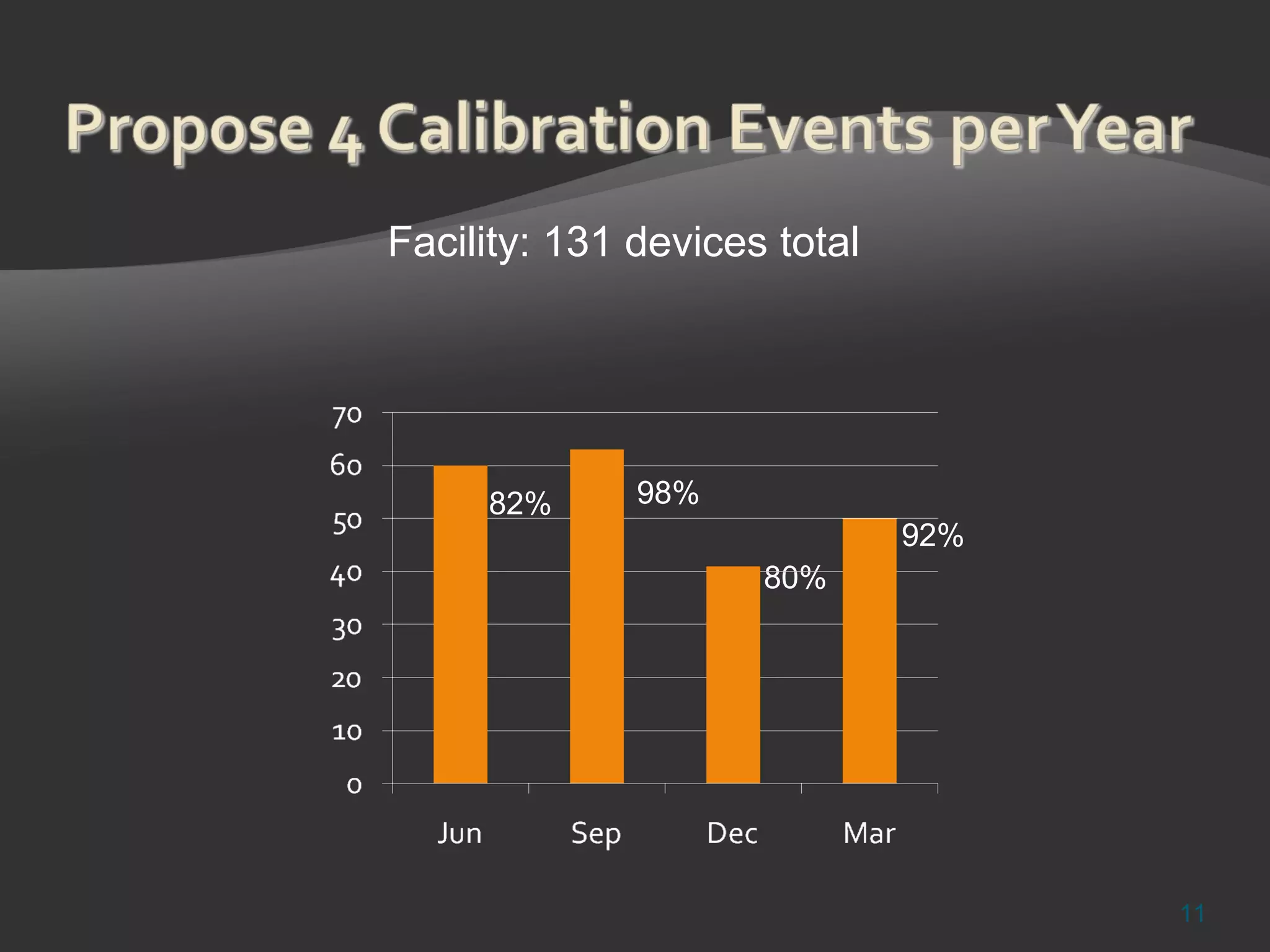

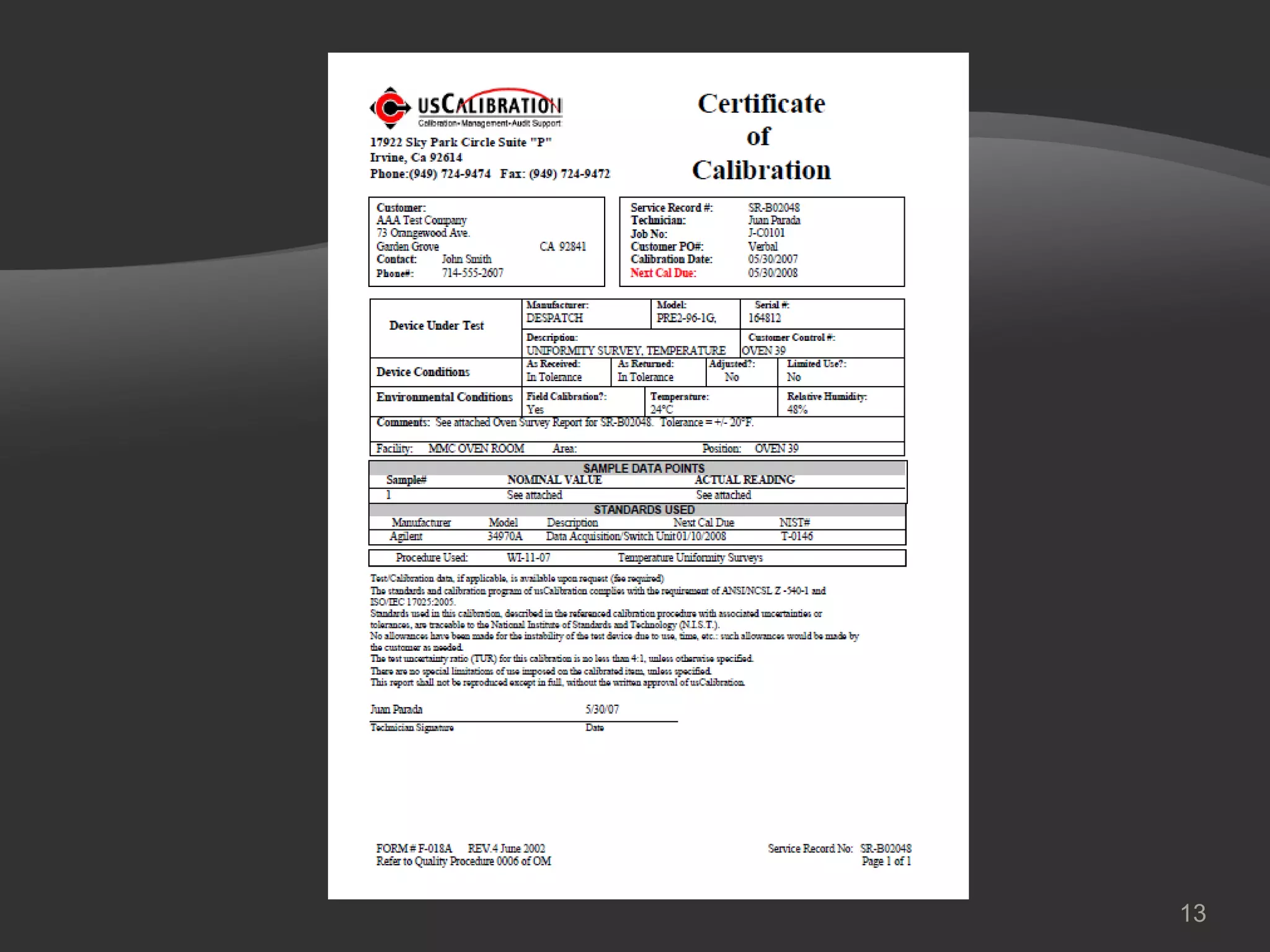

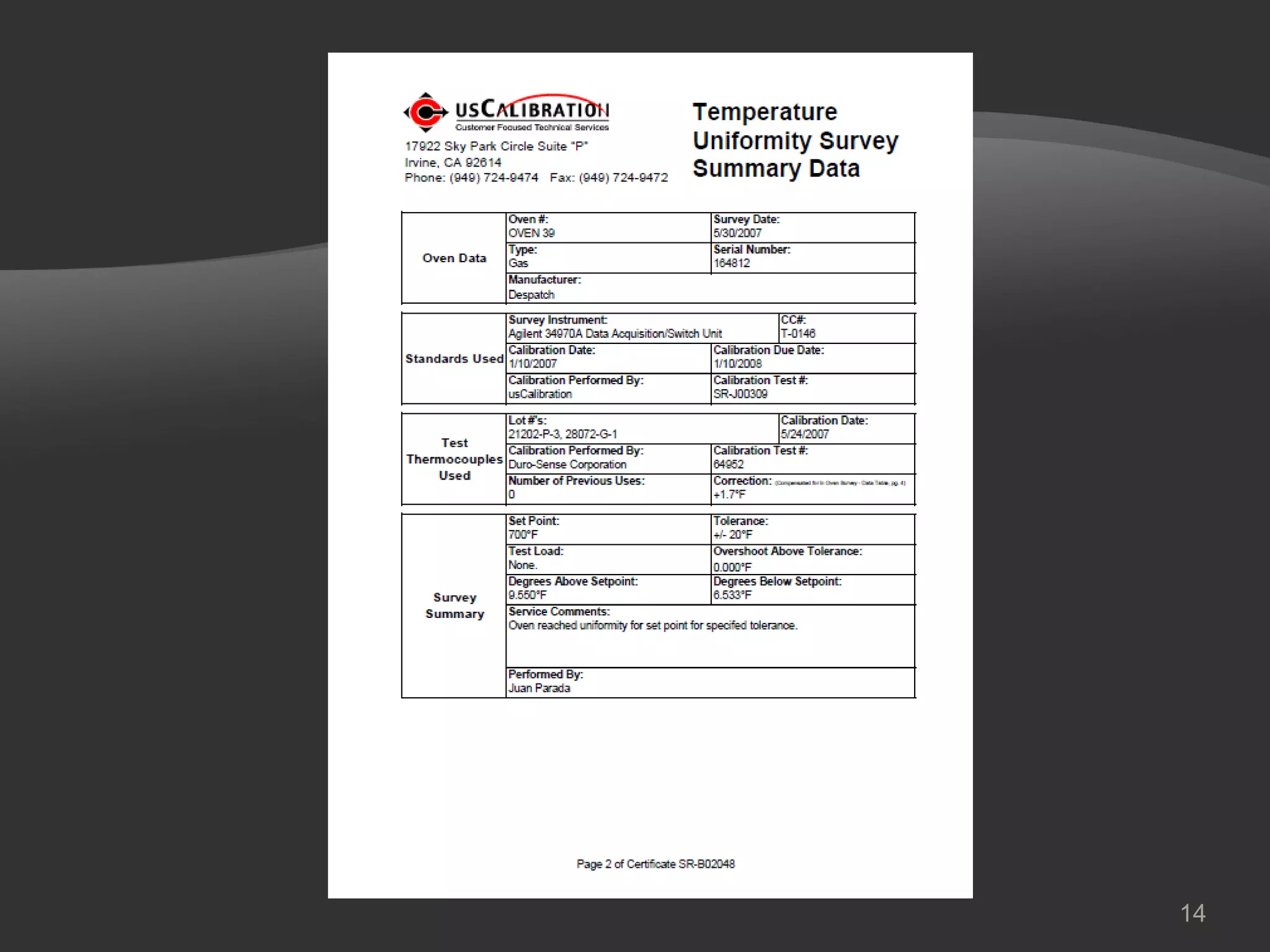

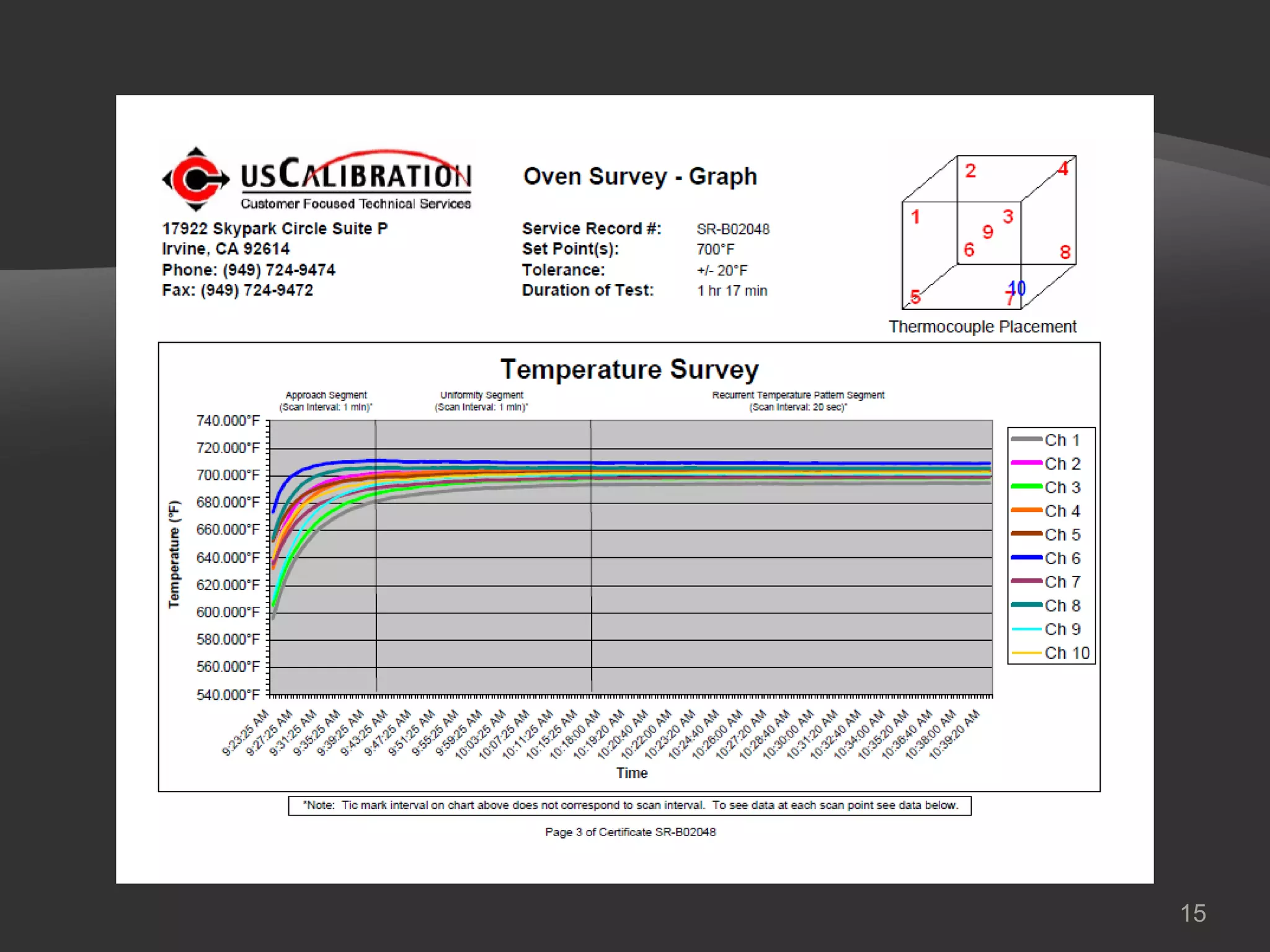

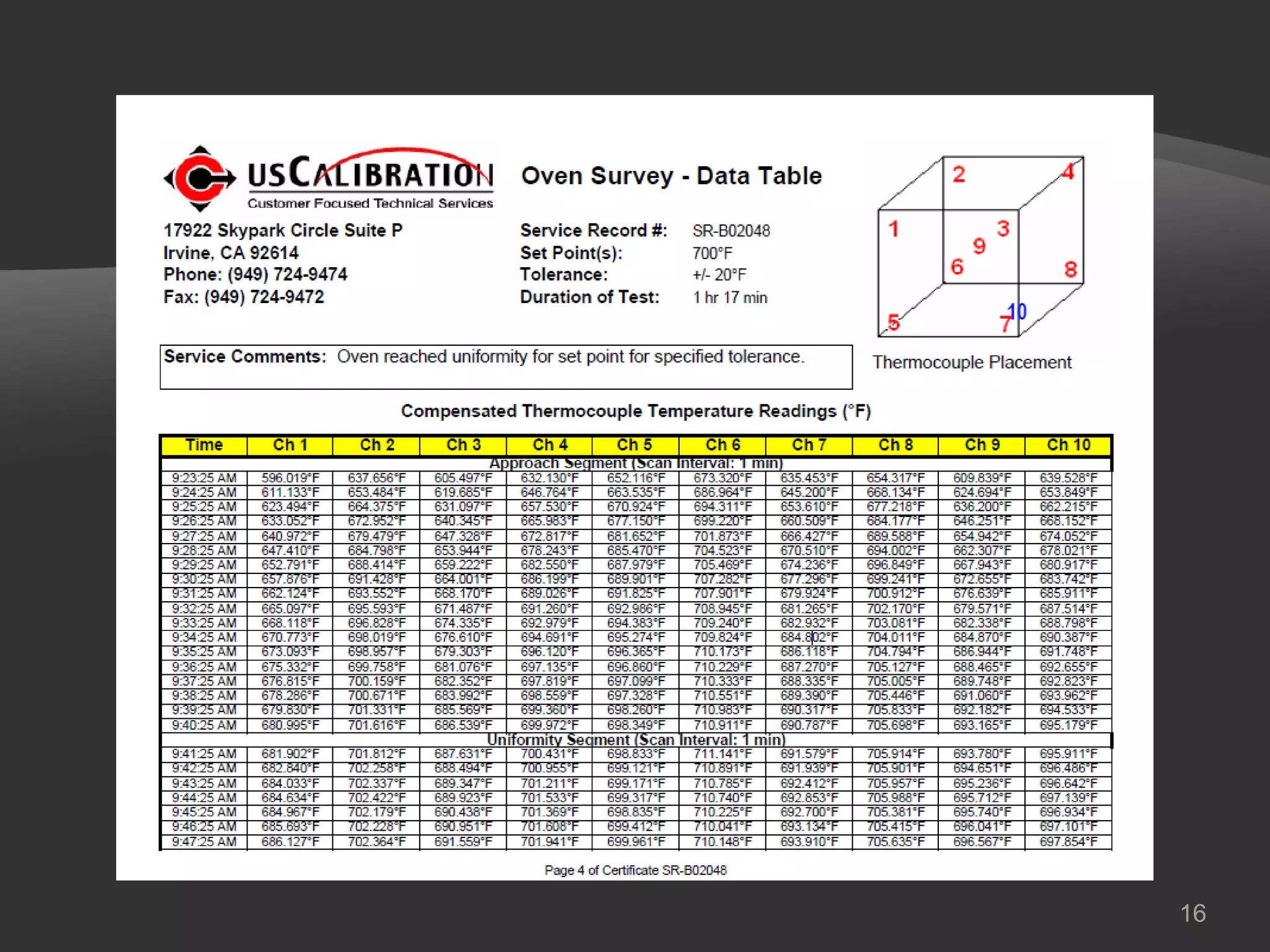

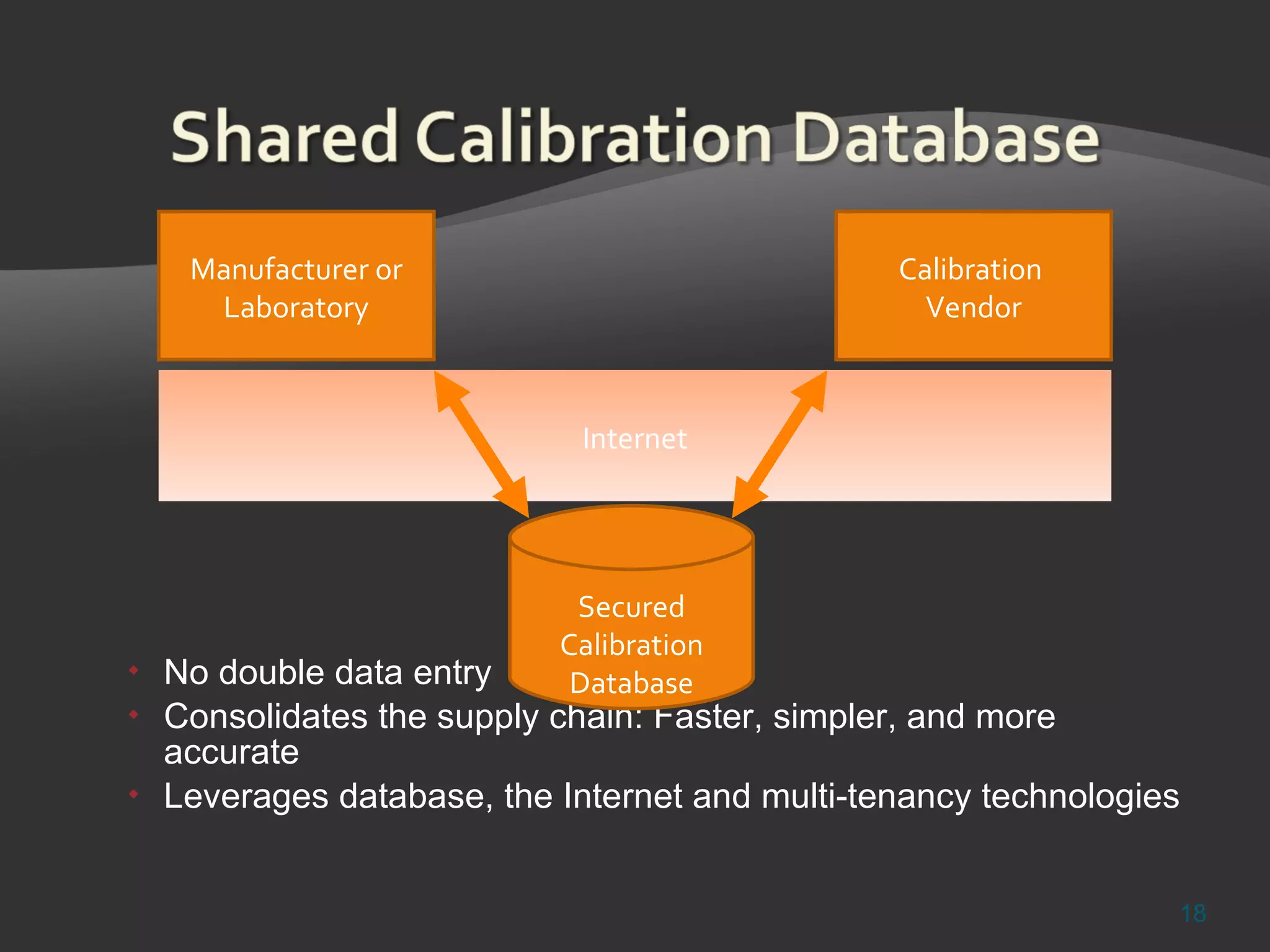

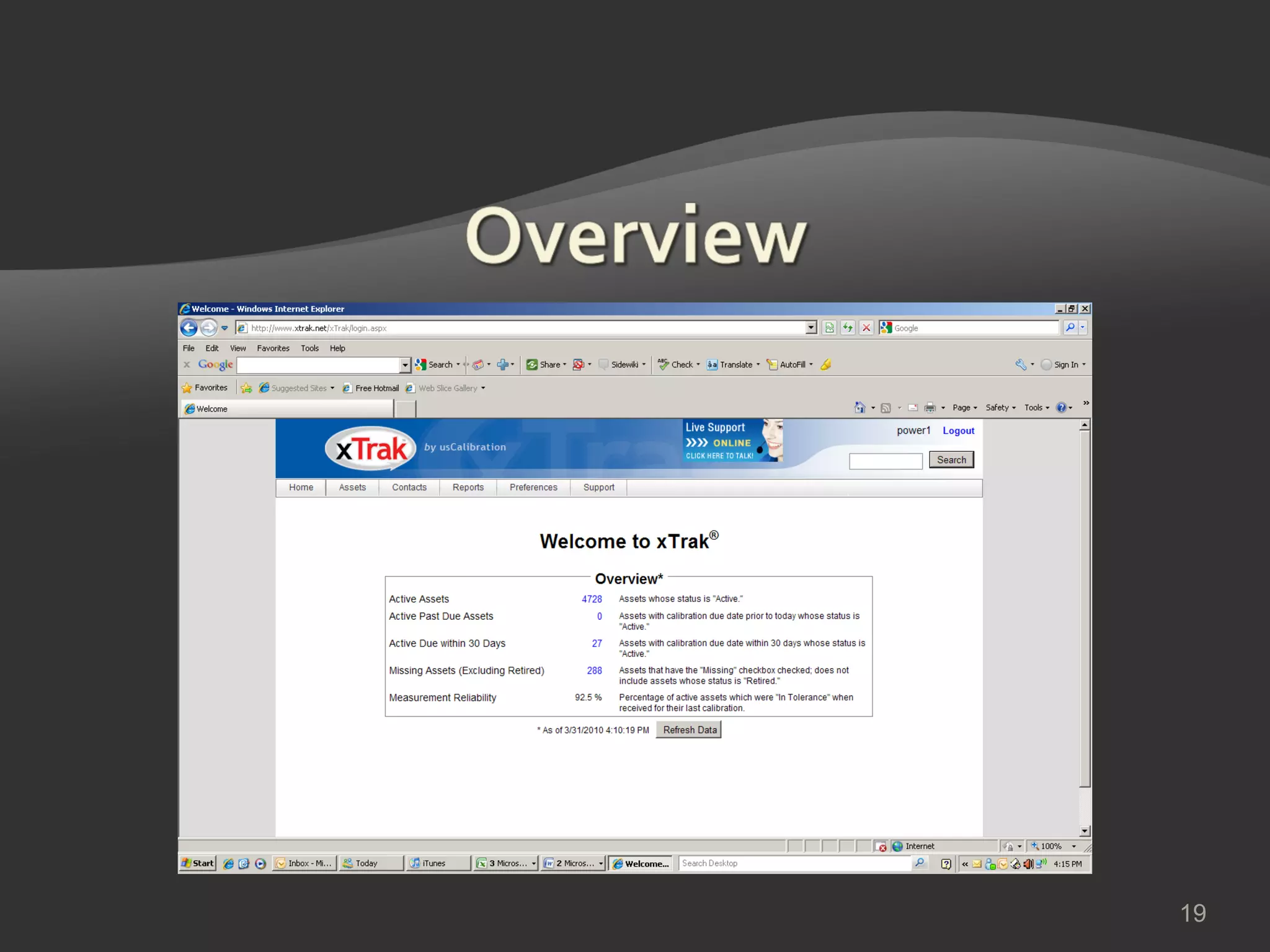

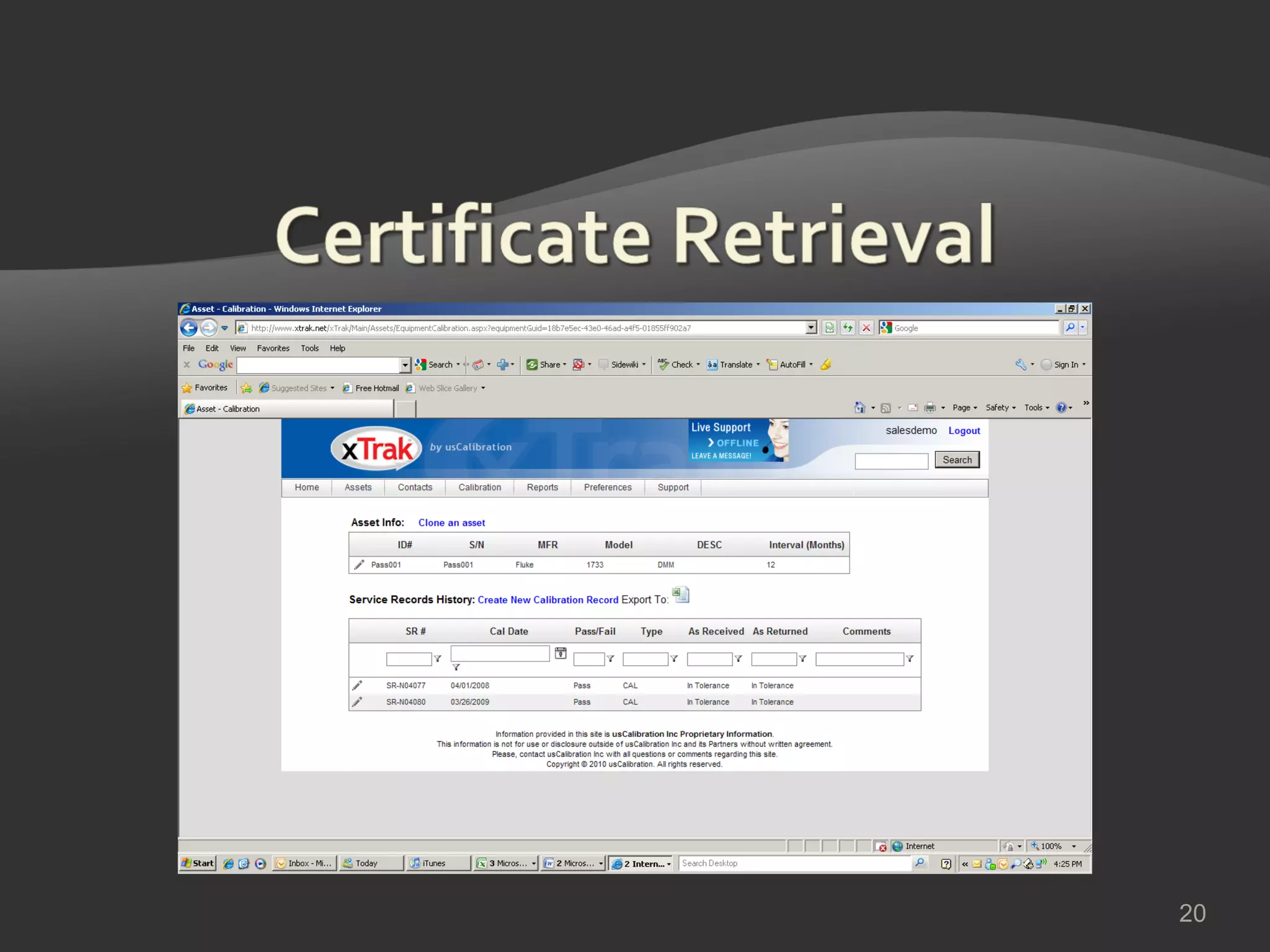

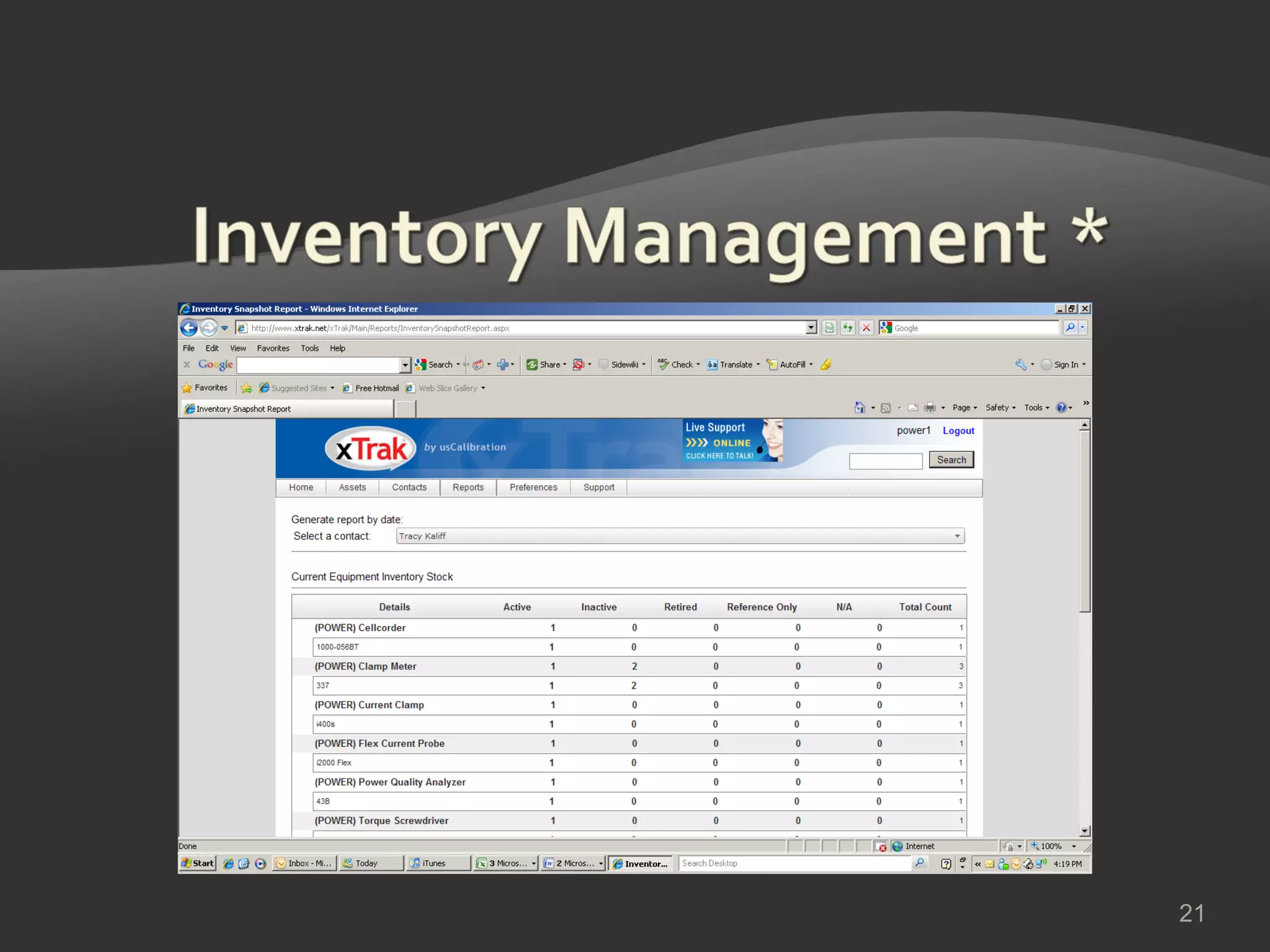

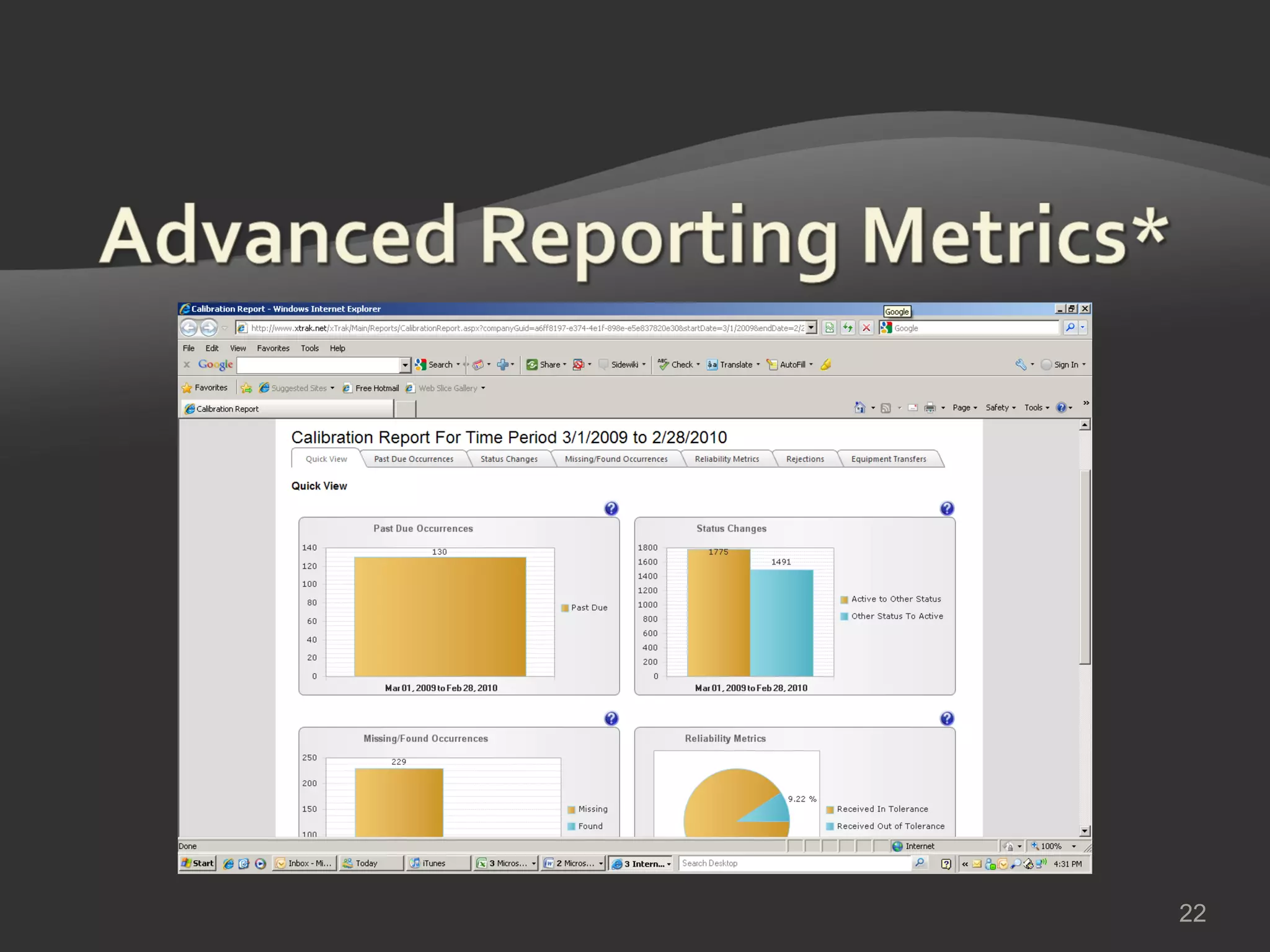

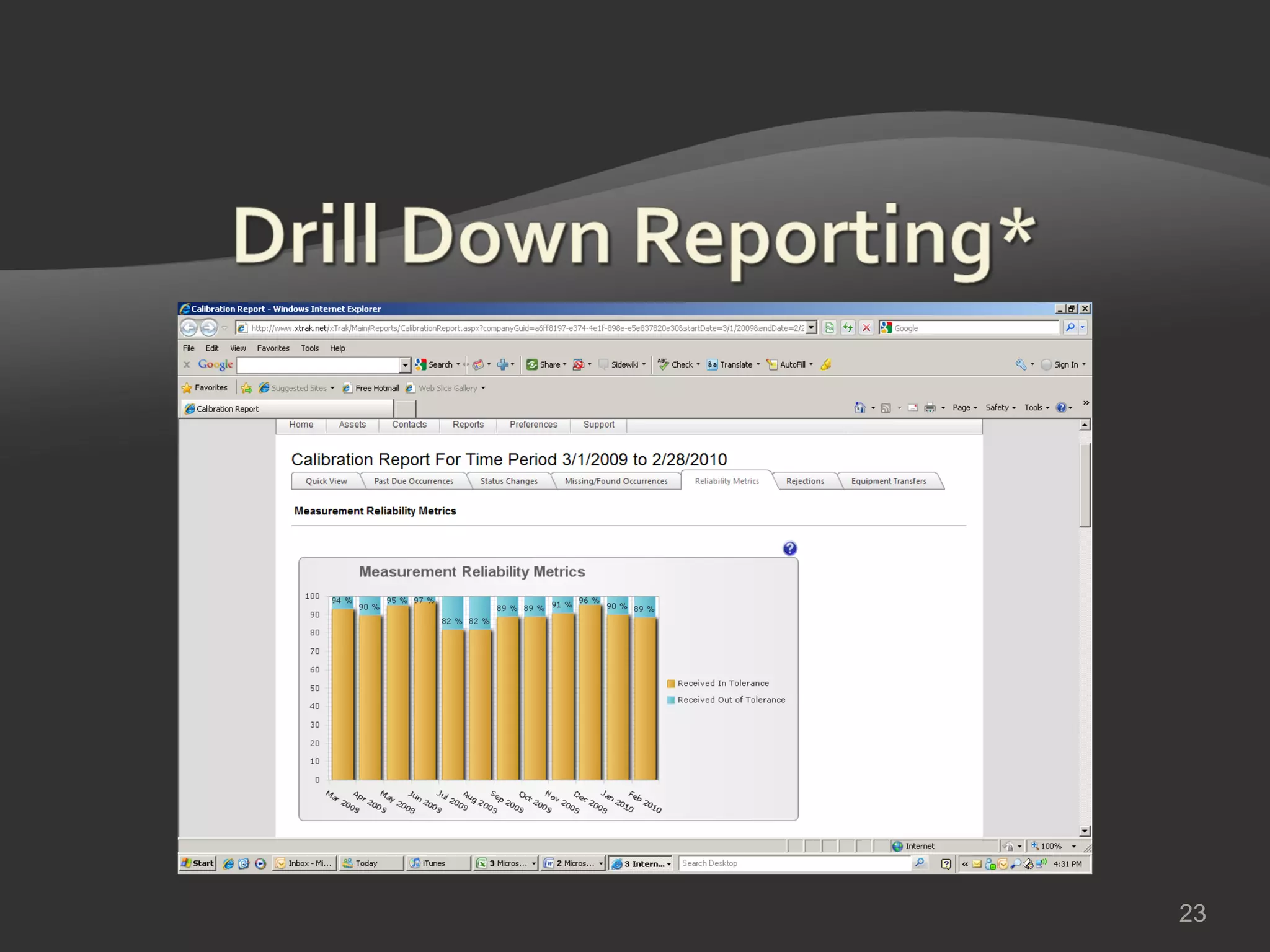

A Lean Calibration Management Program can help companies reduce costs and improve efficiencies by optimizing calibration practices. Common practices that waste time and money include surprise calibrations that impact production, tools being used when past due for calibration, and a lack of control over the calibration process. Applying Lean manufacturing principles like eliminating waste, standardizing processes, and improving workflow can streamline calibration and reduce costs while maintaining quality standards. An online secured calibration database managed by a third-party calibration vendor can consolidate the supply chain and eliminate non-value added tasks like double data entry of calibration records.