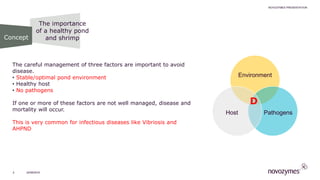

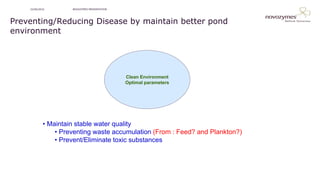

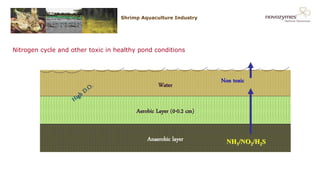

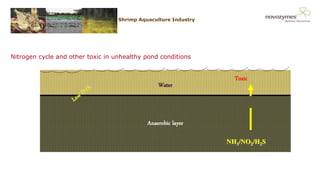

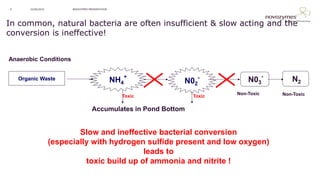

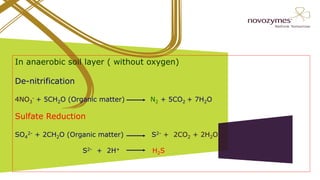

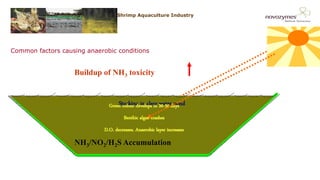

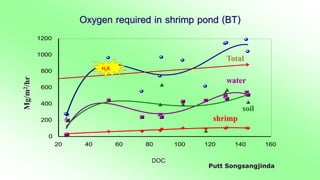

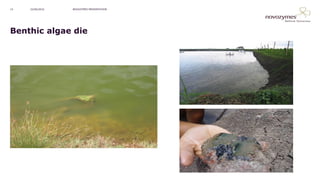

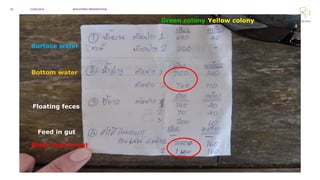

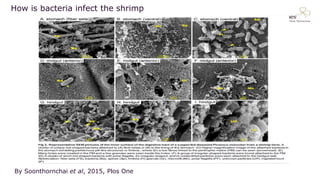

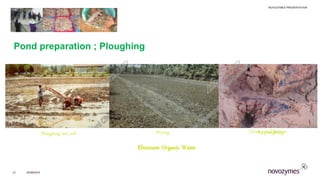

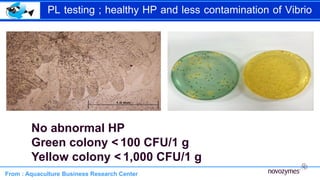

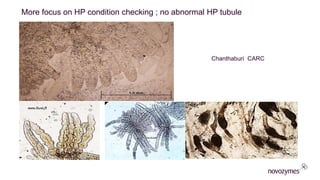

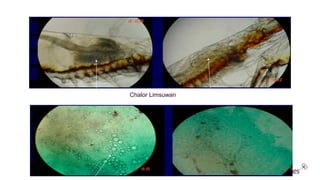

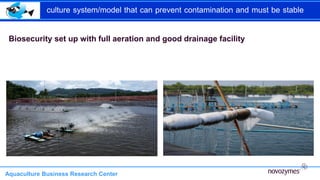

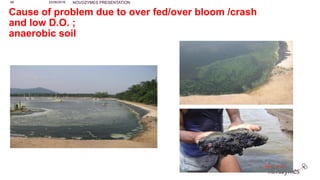

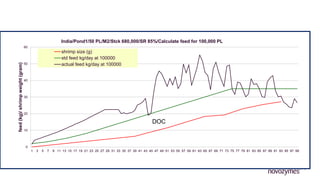

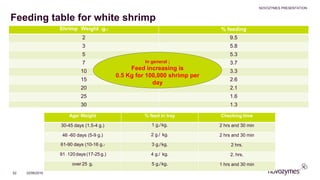

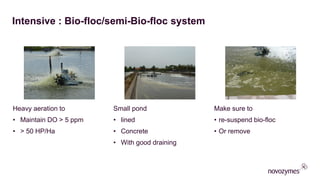

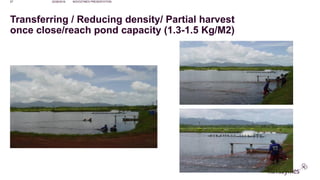

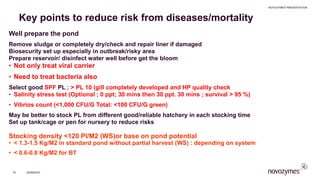

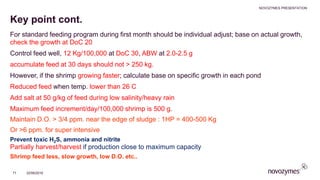

The document outlines basic pond management techniques essential for reducing disease risks in shrimp aquaculture, focusing on the importance of maintaining a stable pond environment, healthy shrimp hosts, and controlling pathogens. Key strategies include regular cleaning of pond soil, proper feeding practices, and ensuring adequate water quality to prevent unhealthy conditions that lead to diseases such as vibriosis. Overall, implementing effective management practices is crucial for the sustainability and health of shrimp farming operations.