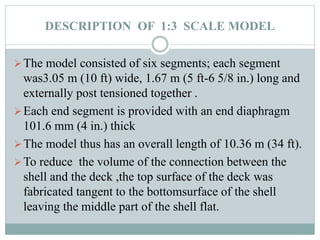

The document discusses a seminar on studying the behavior of hyperbolic cooling tower shells with pipe openings using a 1:50 scale model subjected to seismic loads. Hyperbolic cooling towers are large reinforced concrete structures that extract heat from water to cool it. The seminar focuses on analyzing a scaled down model of a cooling tower subjected to earthquake loads. Sensors are placed on the model to measure strains and deflections under simulated seismic conditions to understand how the structure responds.