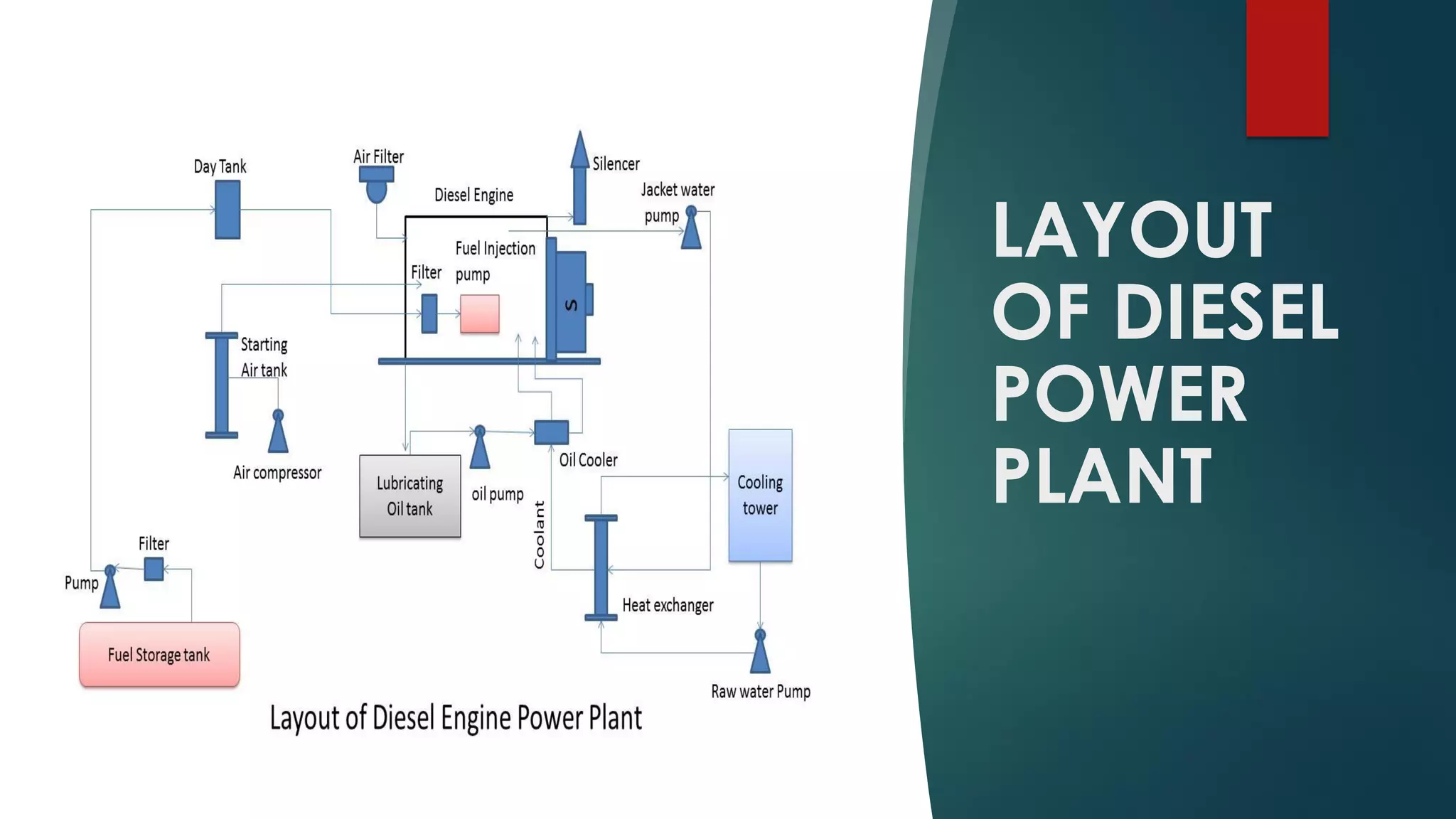

A diesel power plant uses a diesel engine as the prime mover to generate electricity. It typically generates 2-50 MW of power. The main components are the diesel engine, air intake system, fuel supply system, exhaust system, cooling system, lubricating system, and starting system. The diesel engine compresses air which is then mixed with fuel and ignited. The engine is directly coupled to a generator to produce electricity. The plant has advantages of simple design, quick start up, and ability to handle varying loads. Disadvantages include high operating costs, noise issues, and inability to be constructed at a large scale.