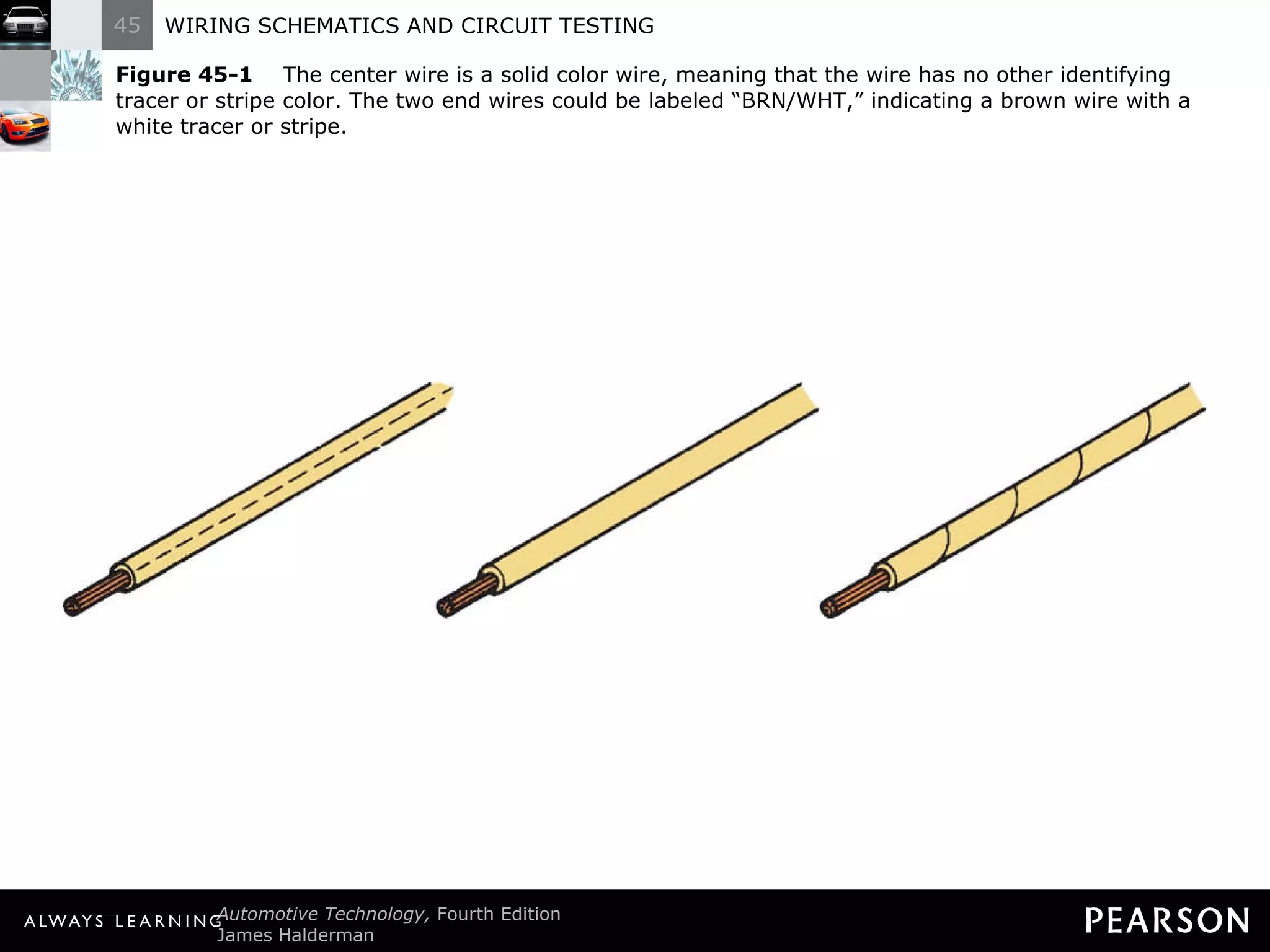

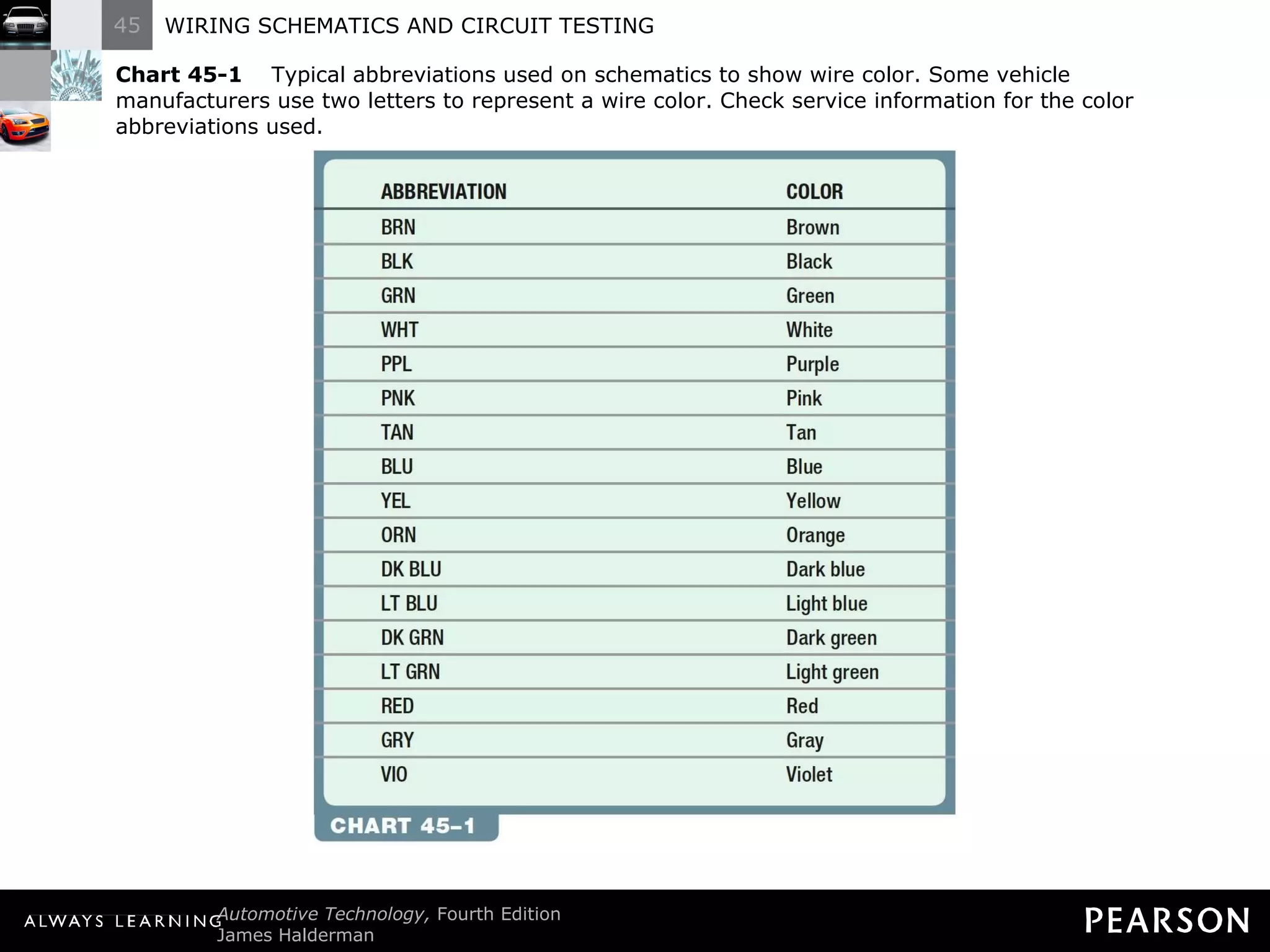

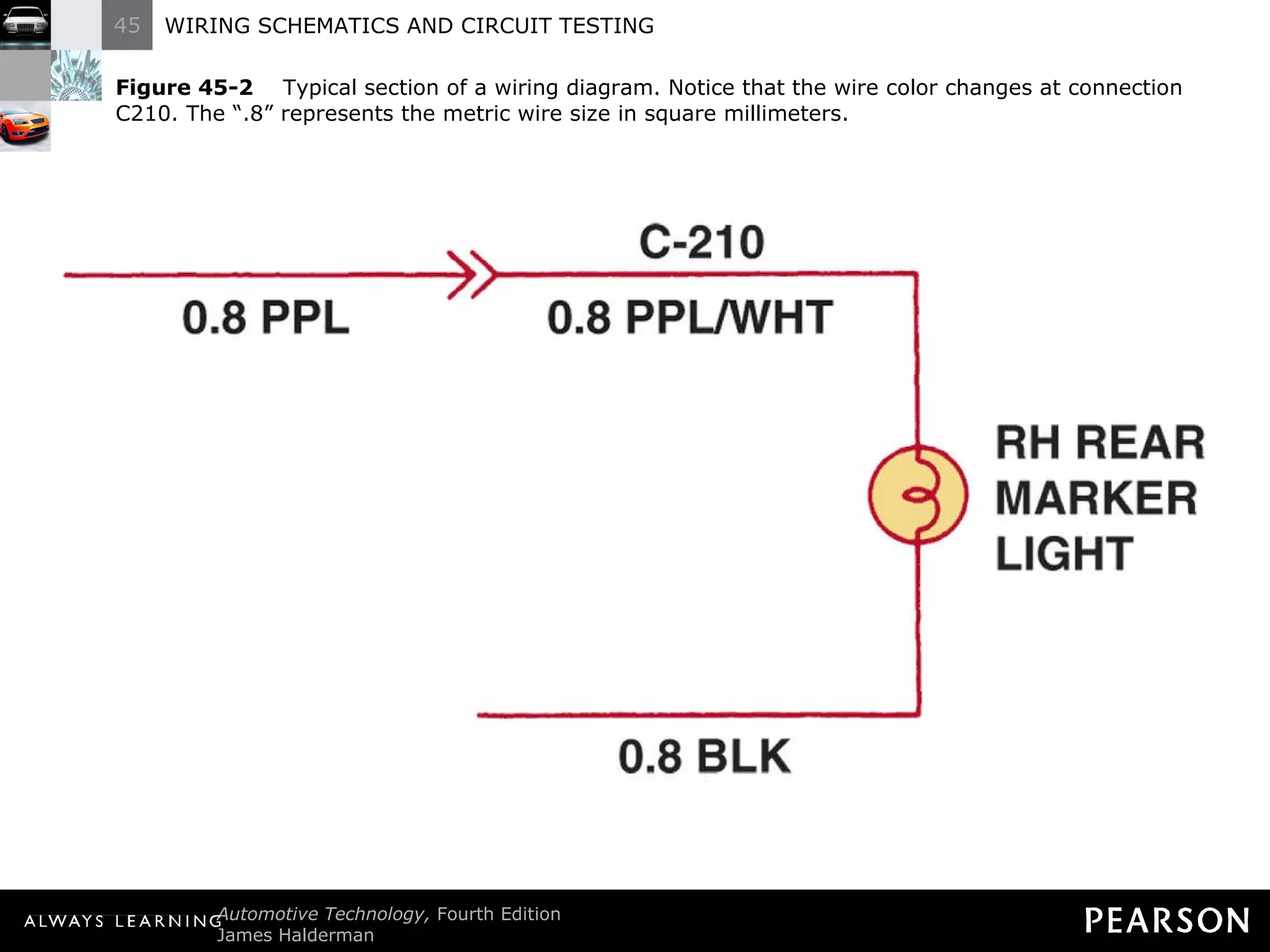

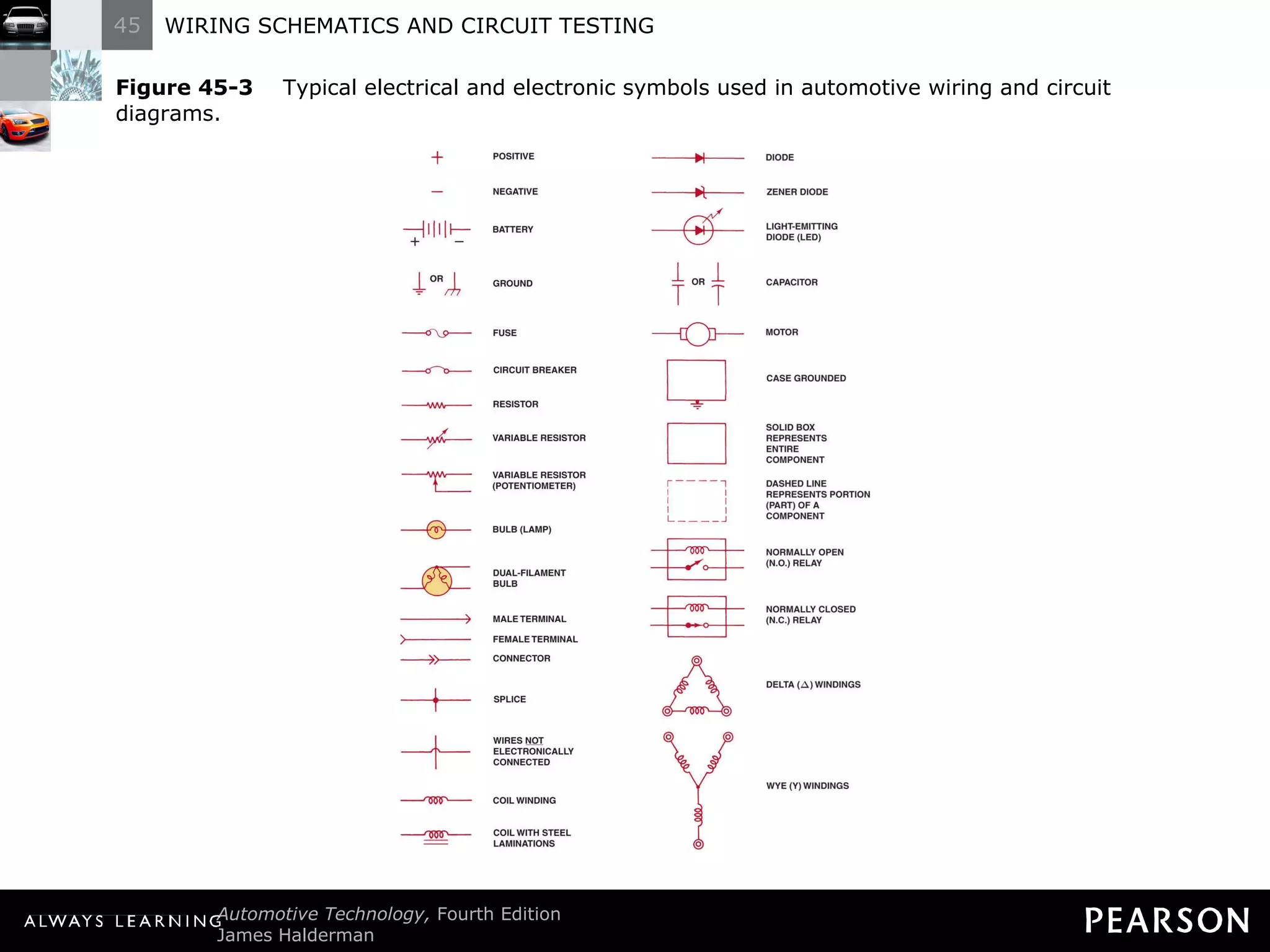

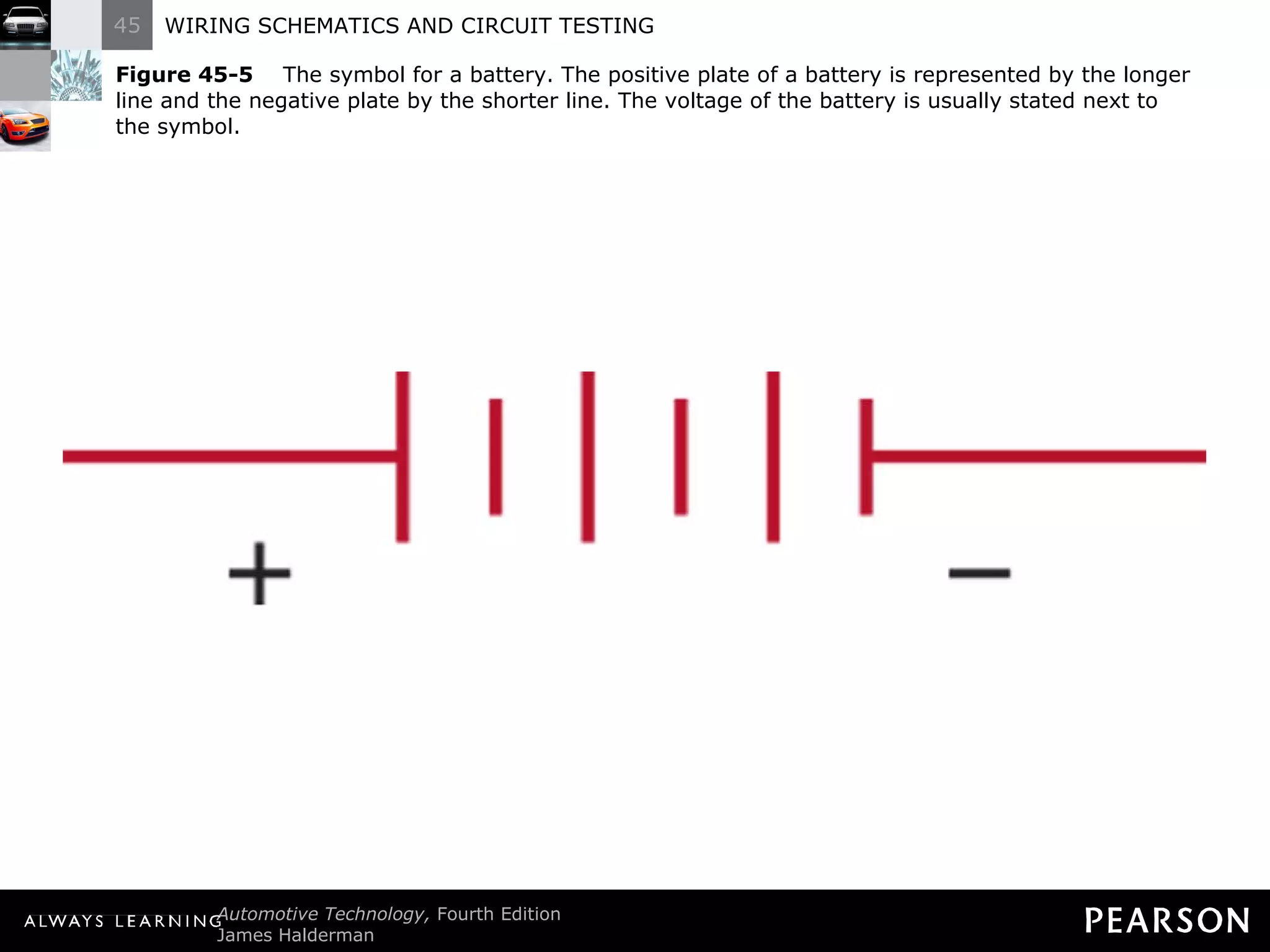

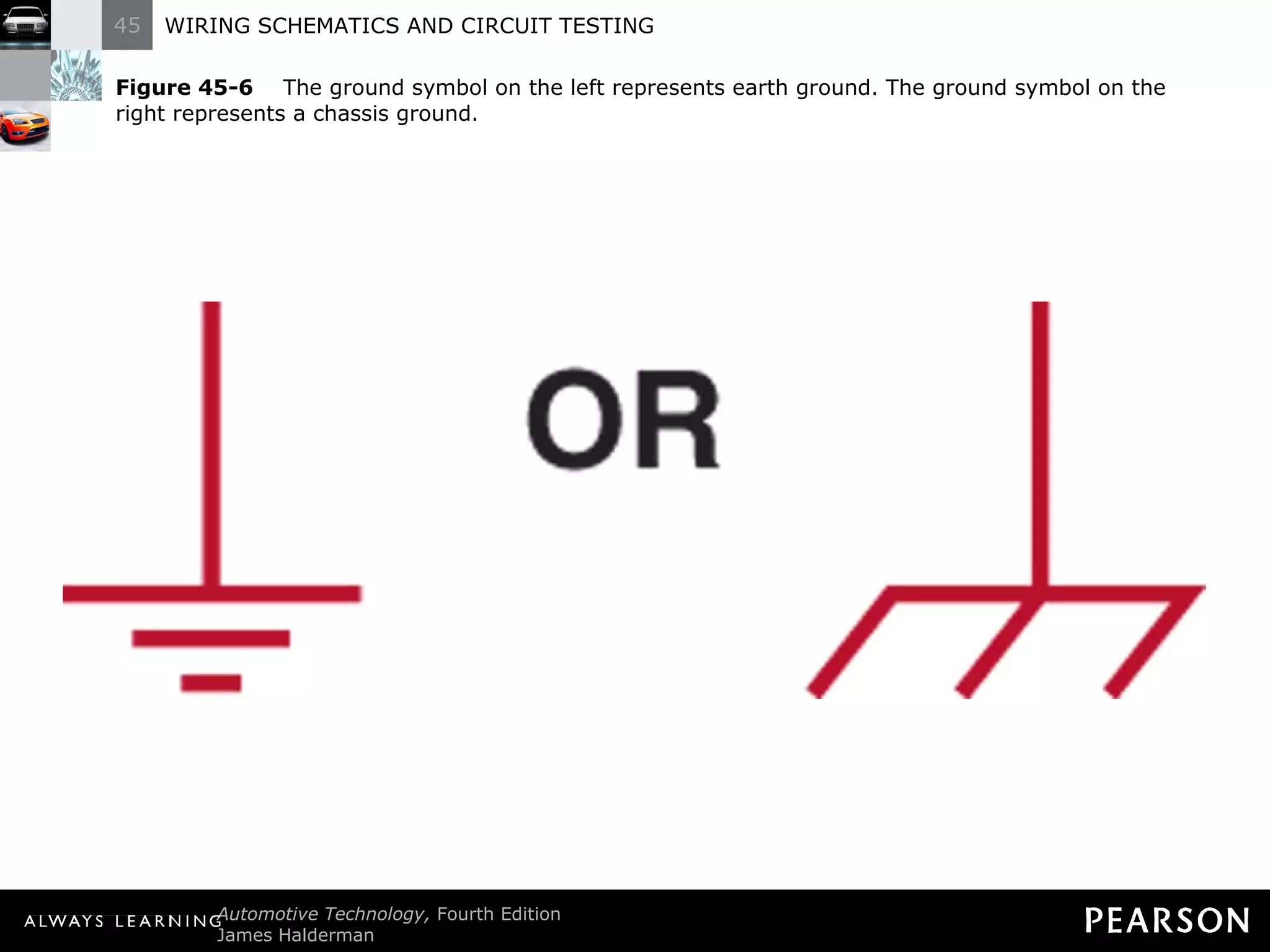

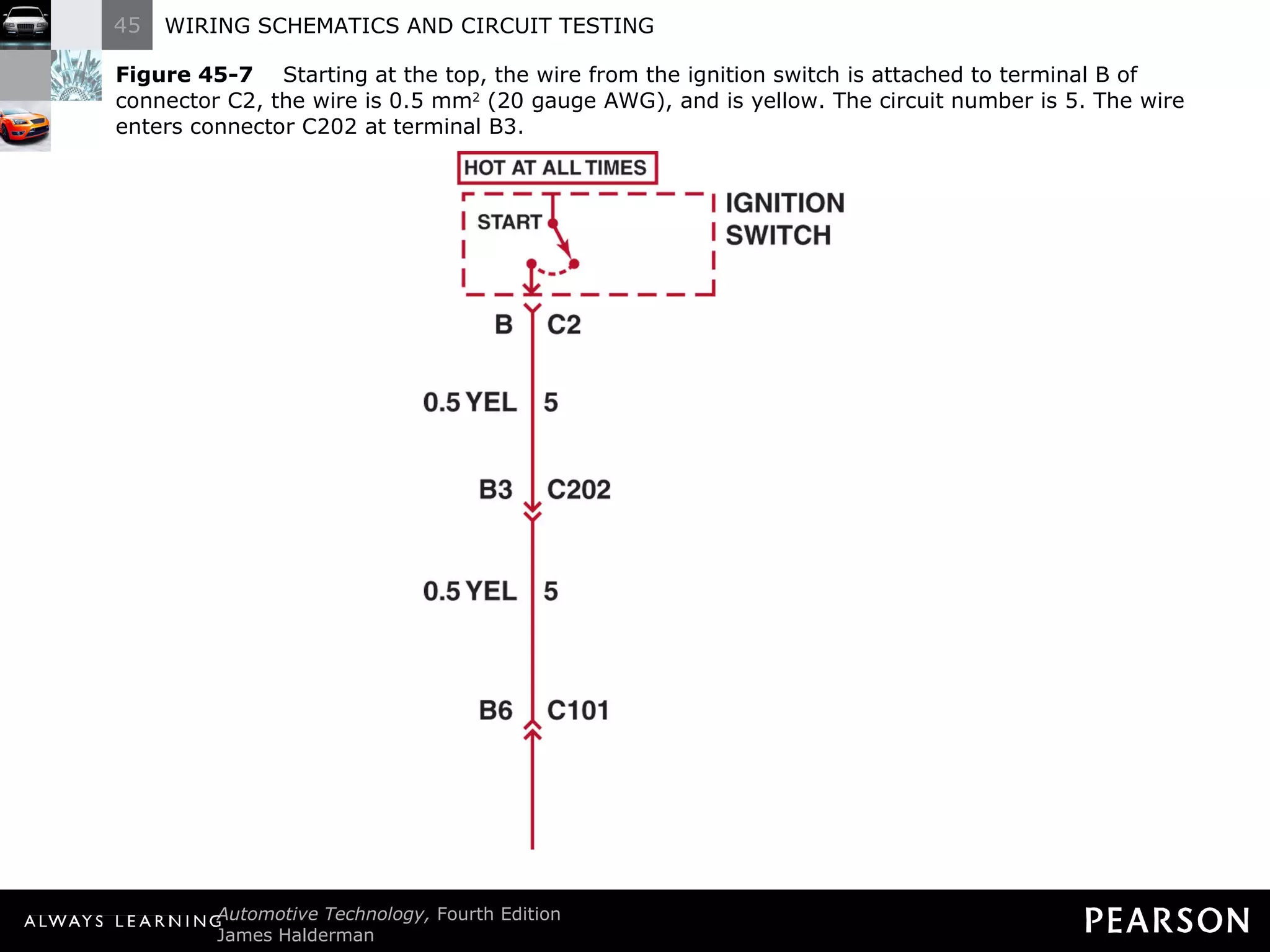

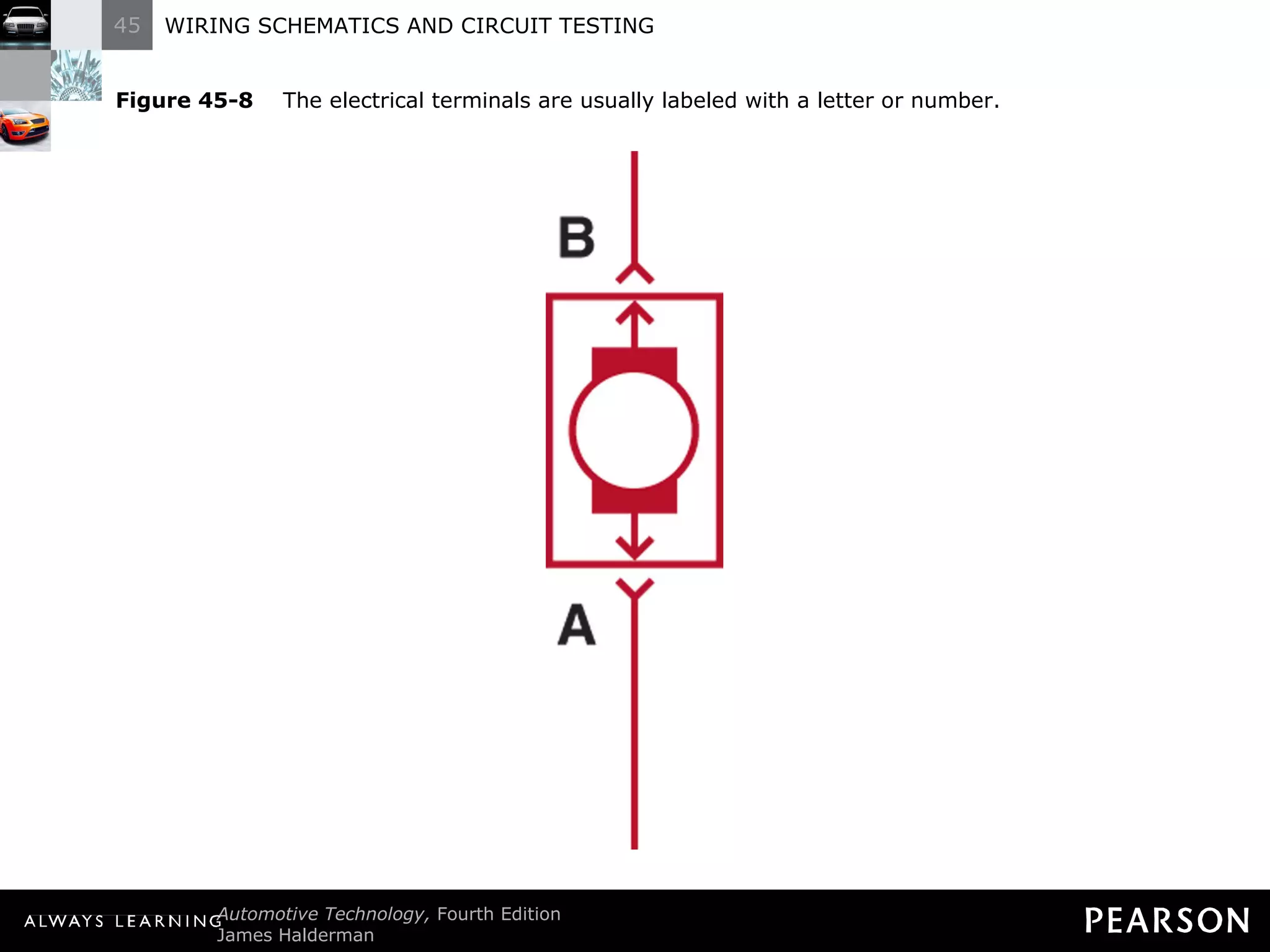

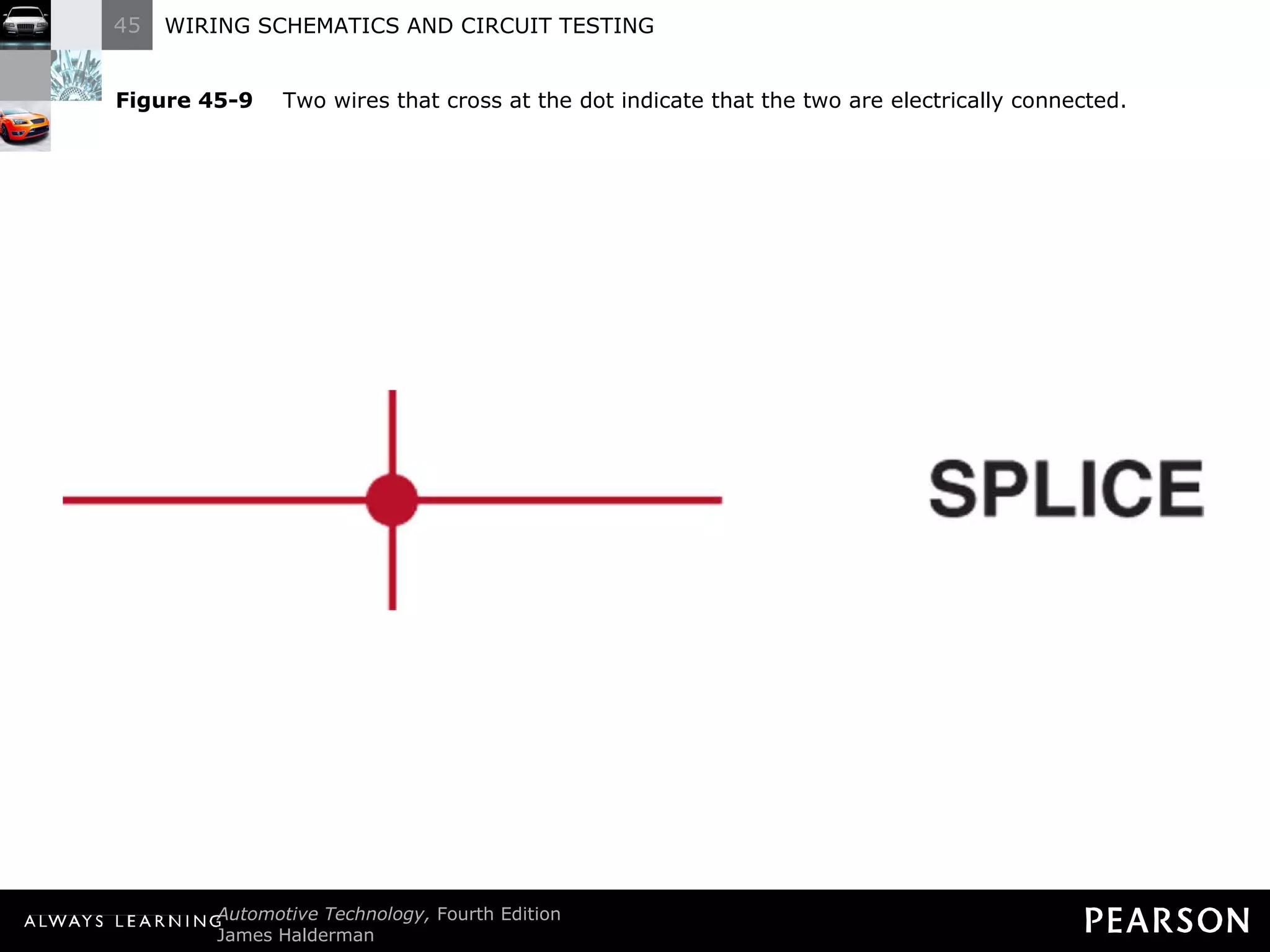

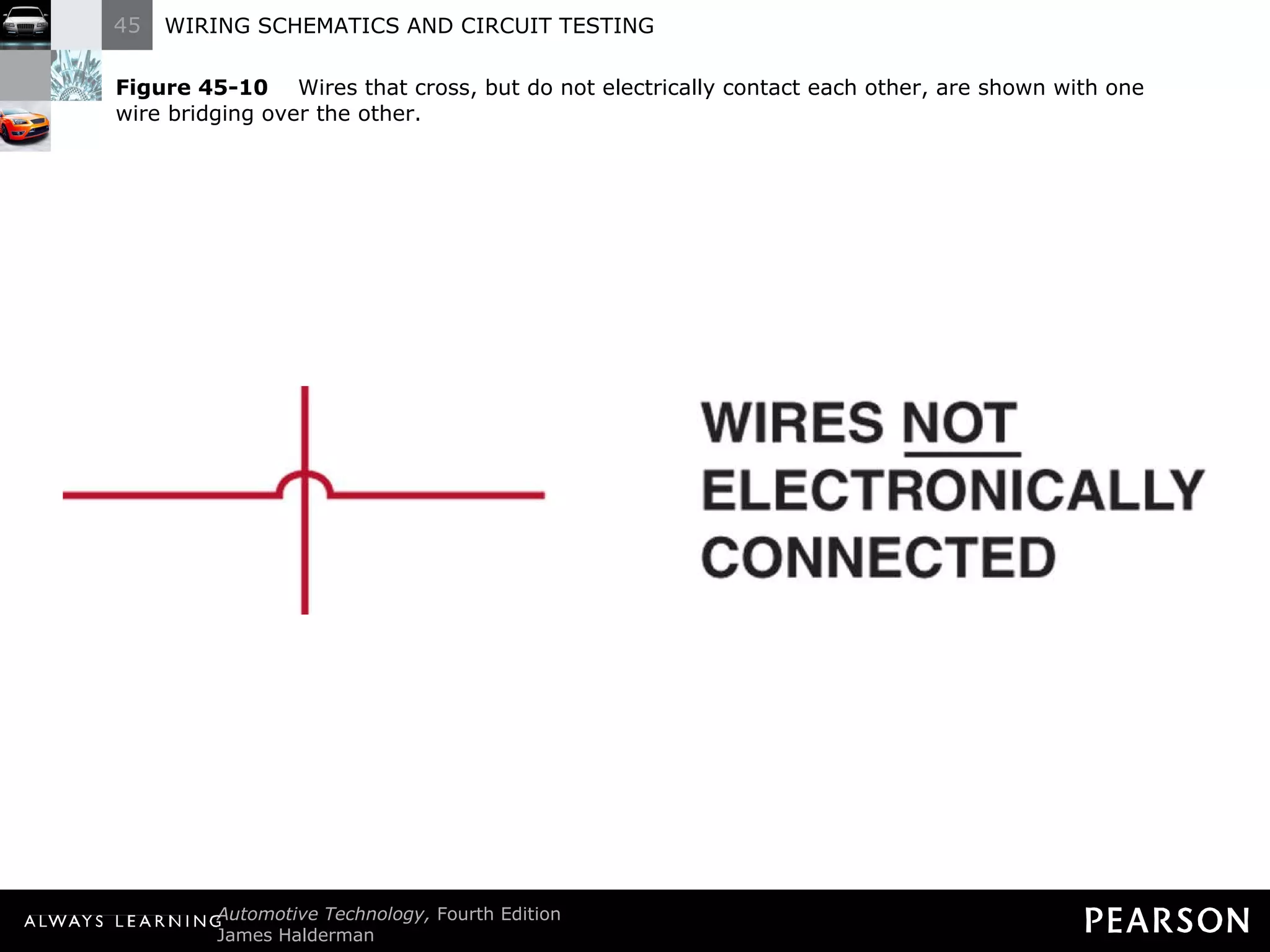

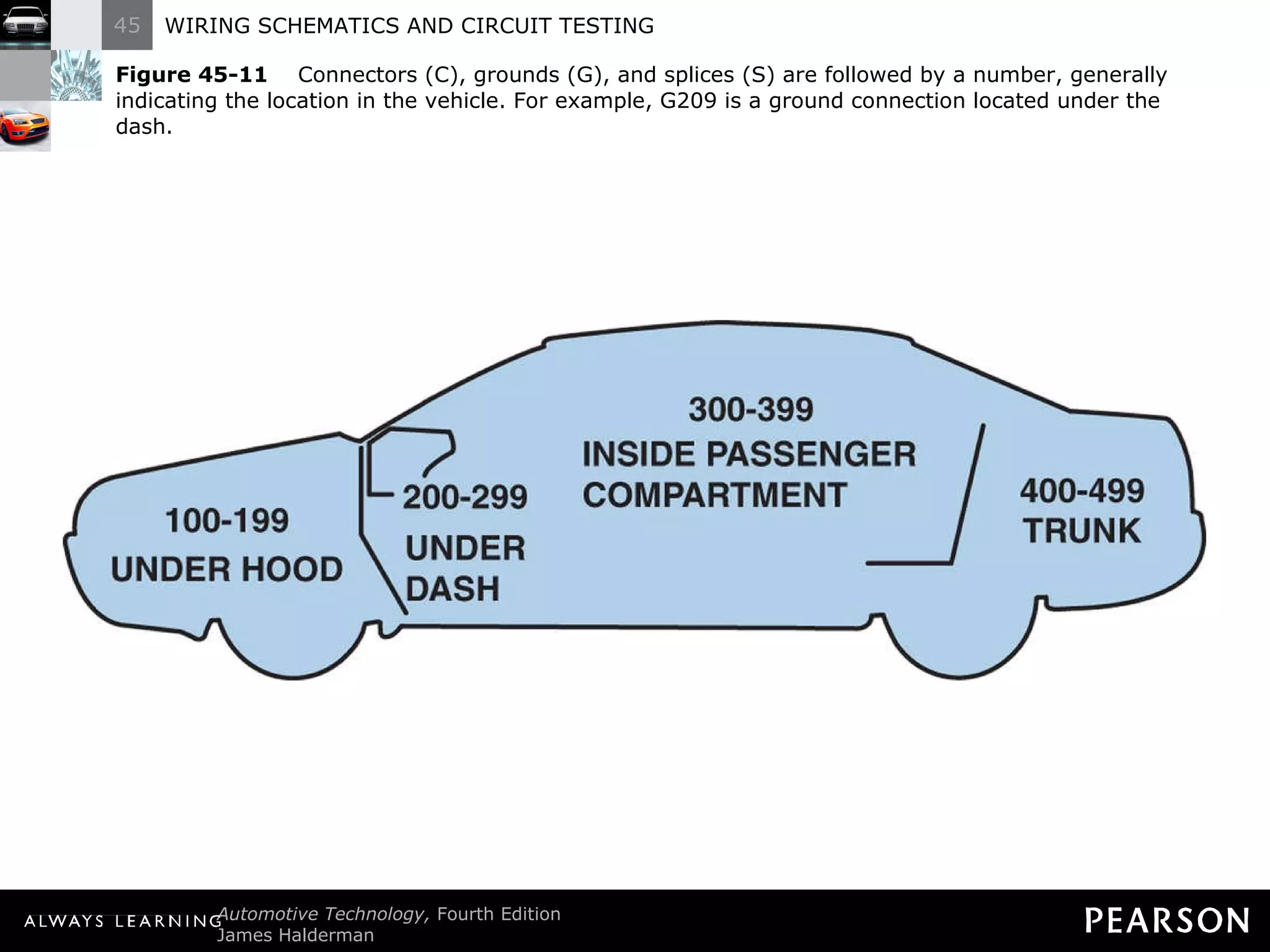

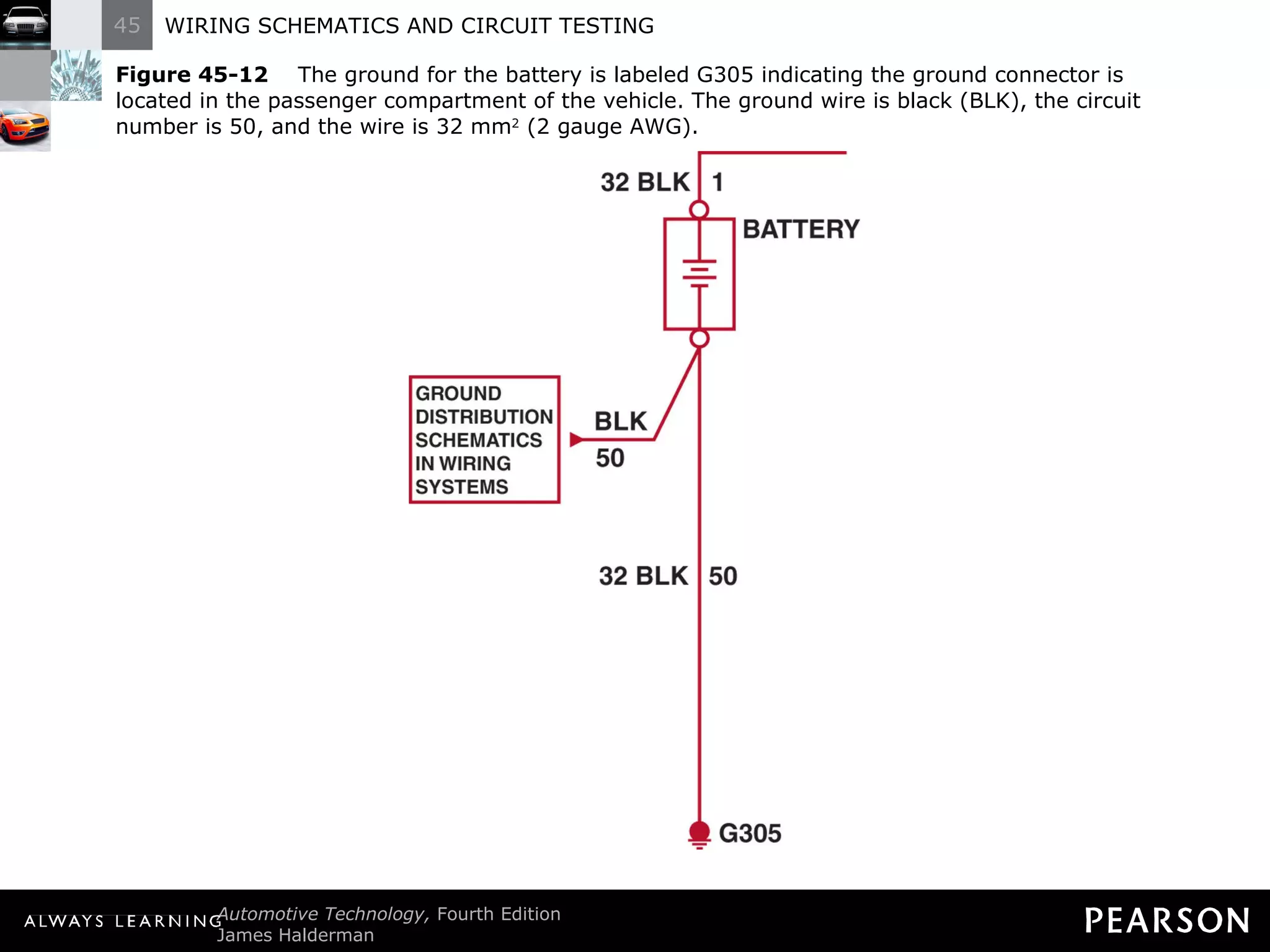

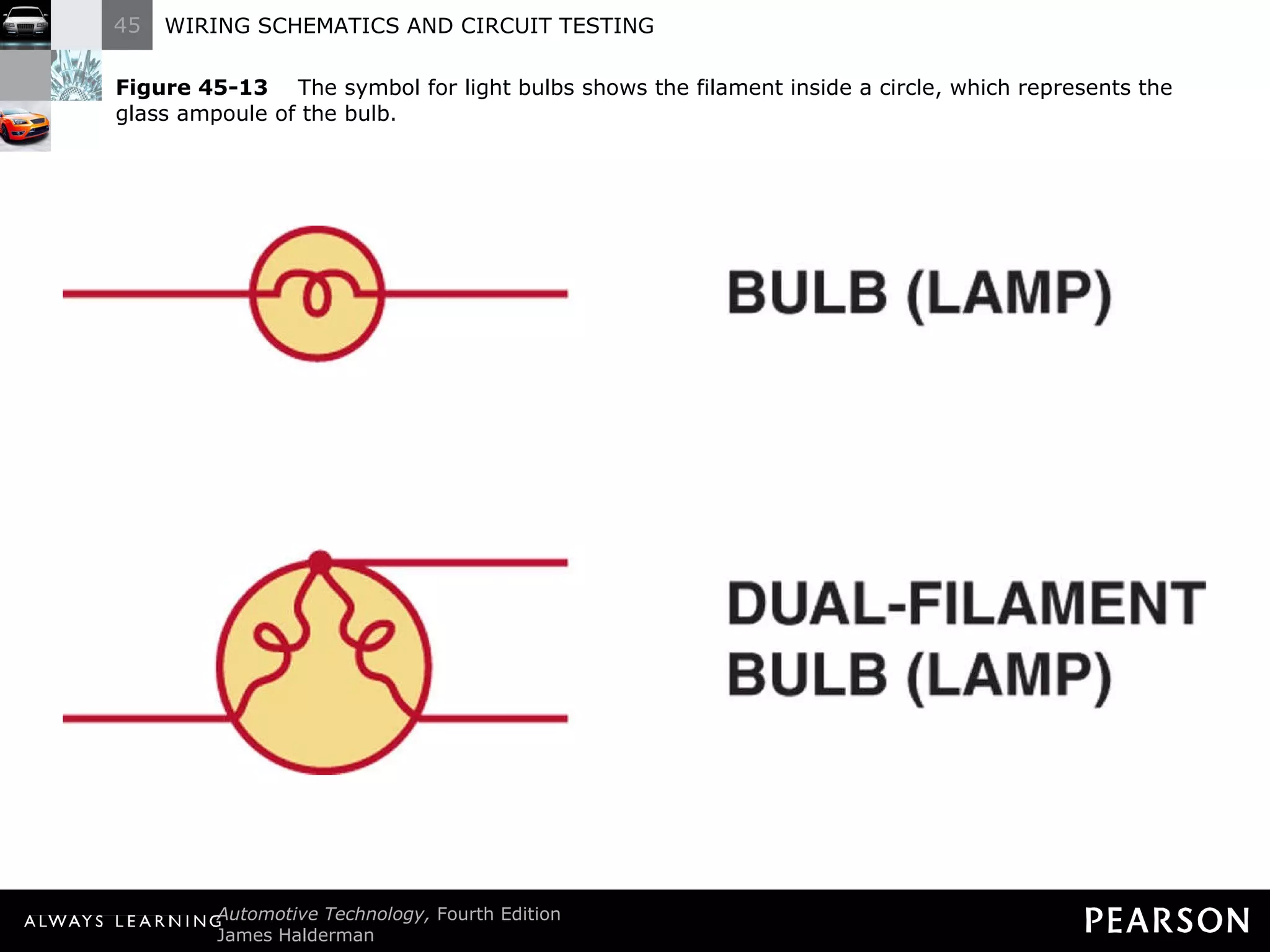

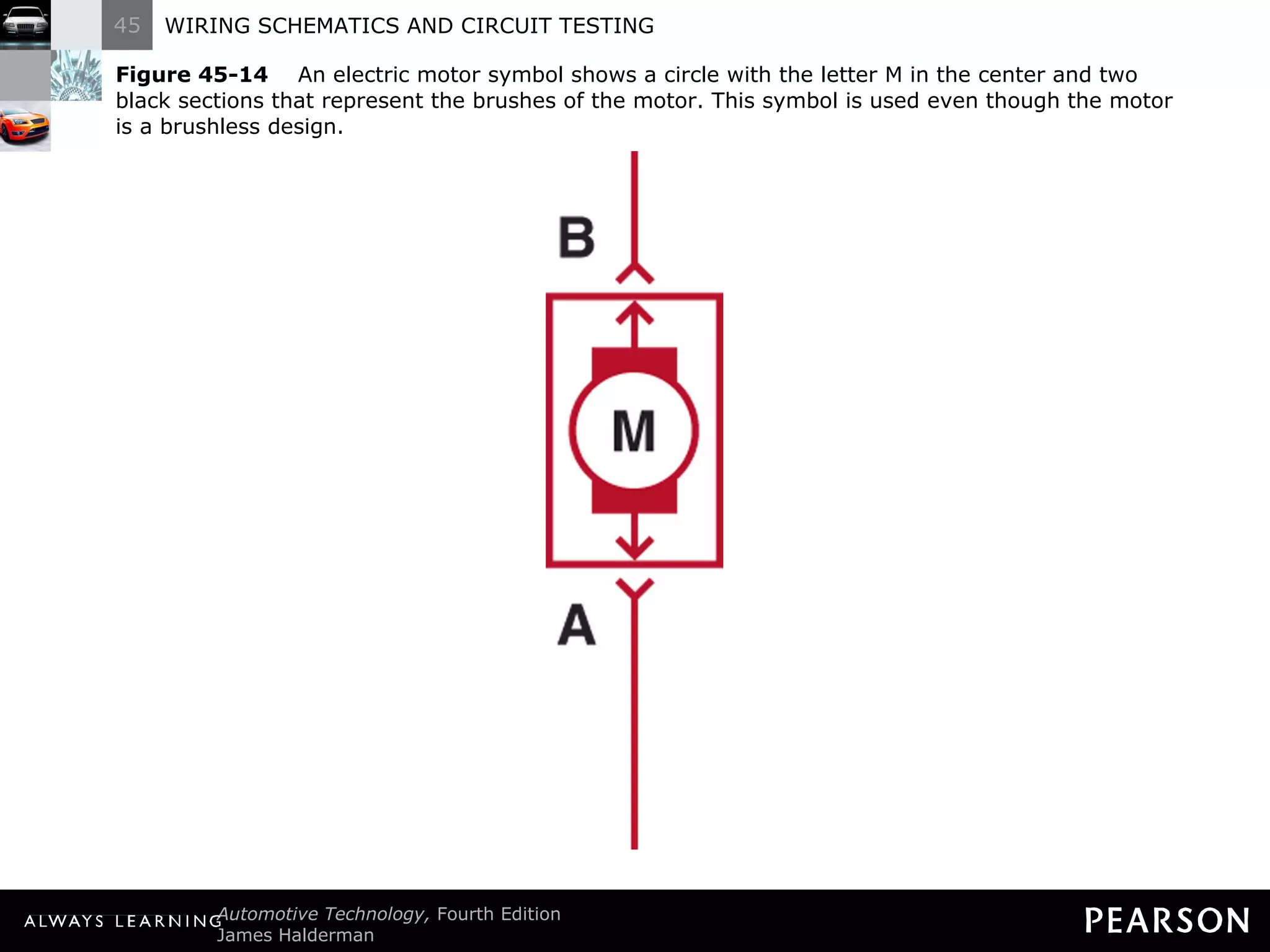

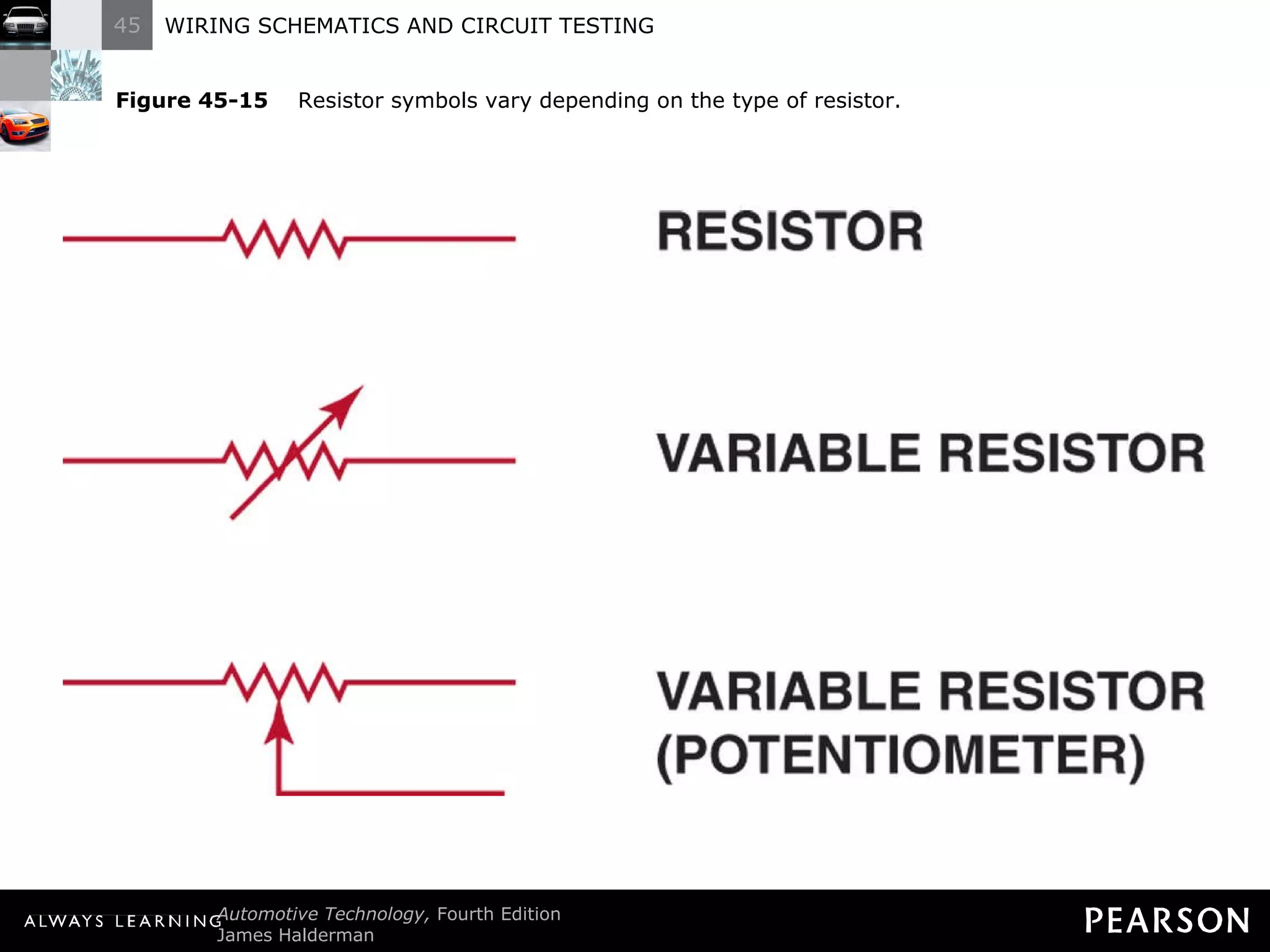

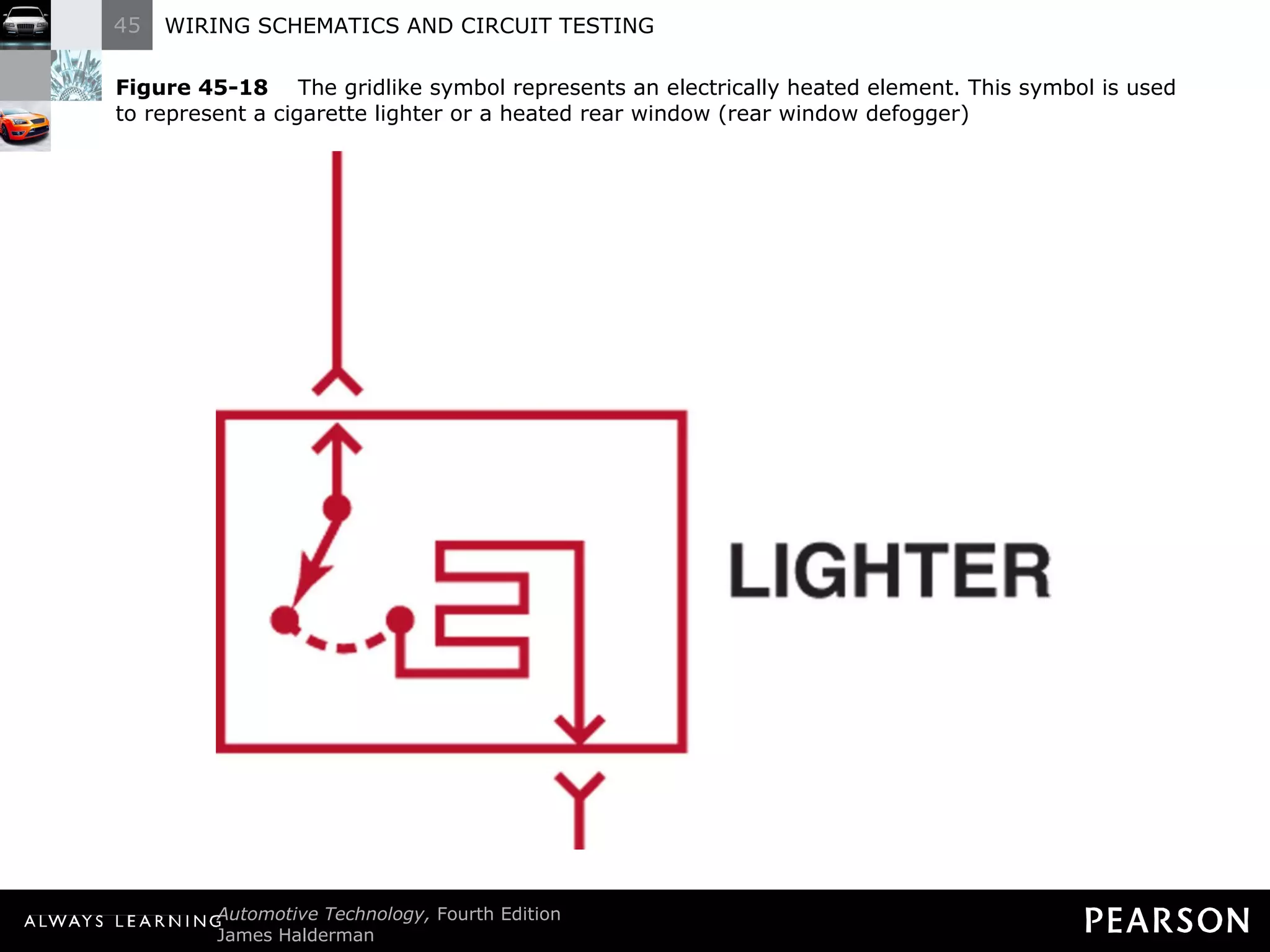

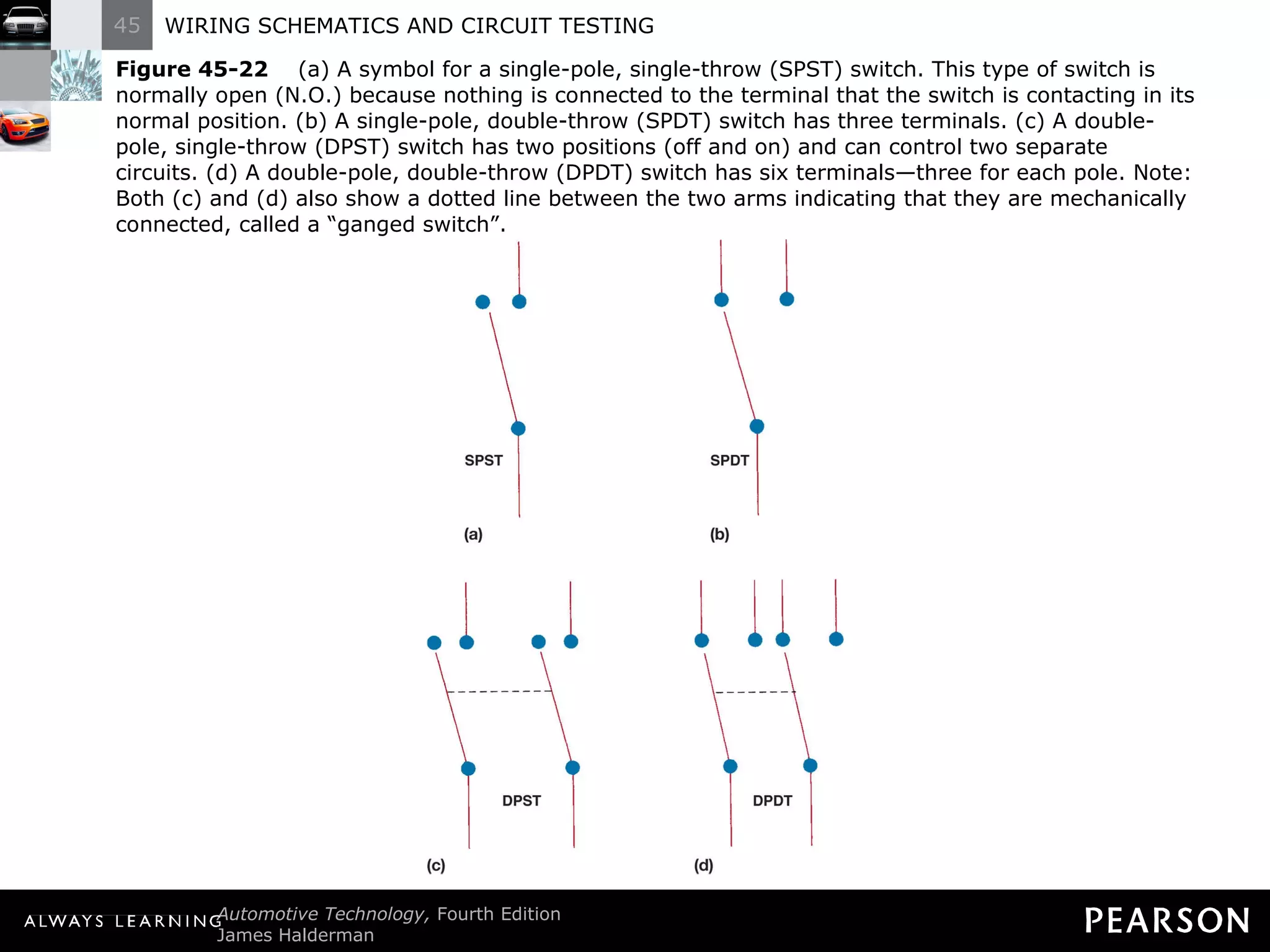

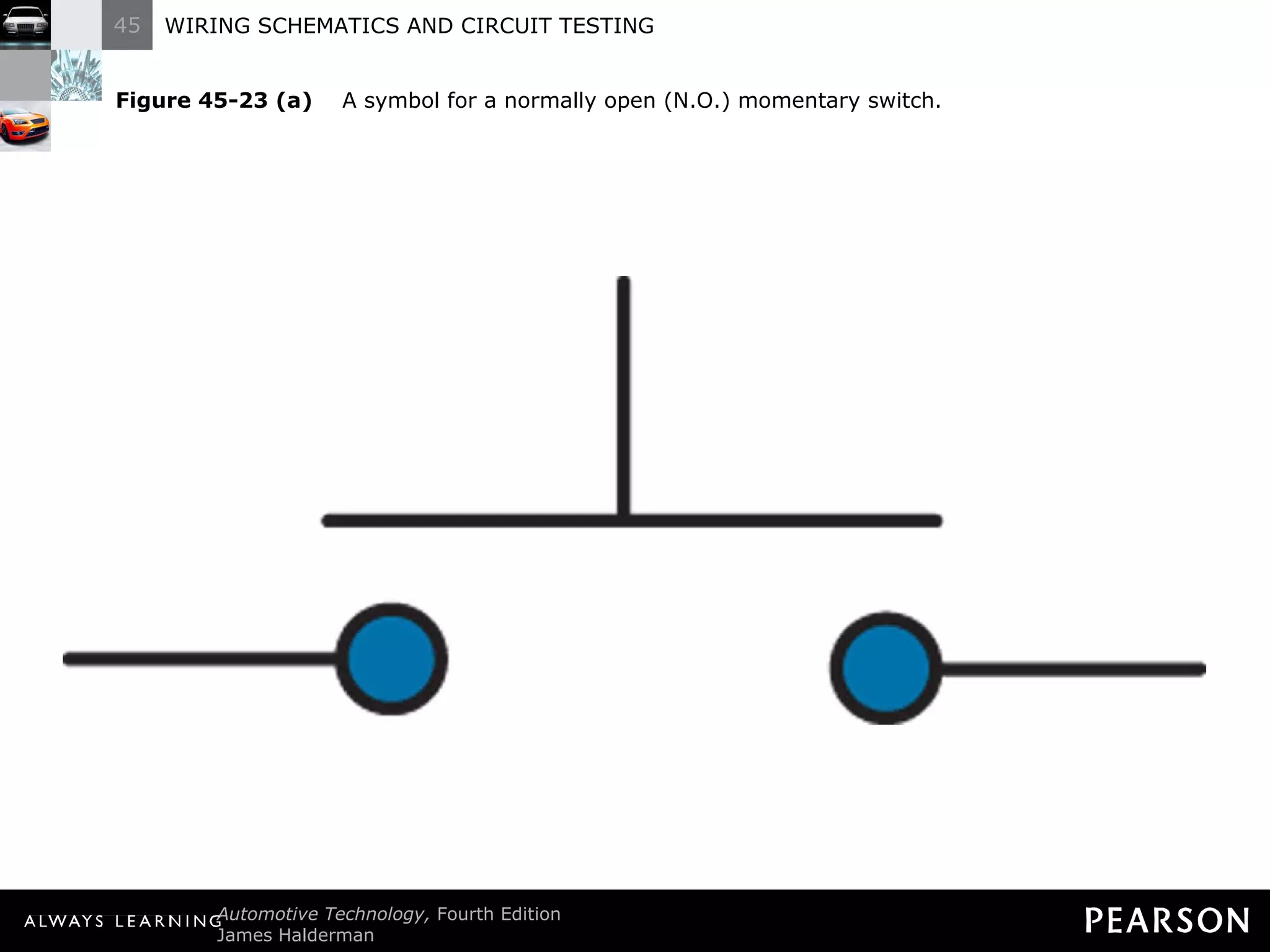

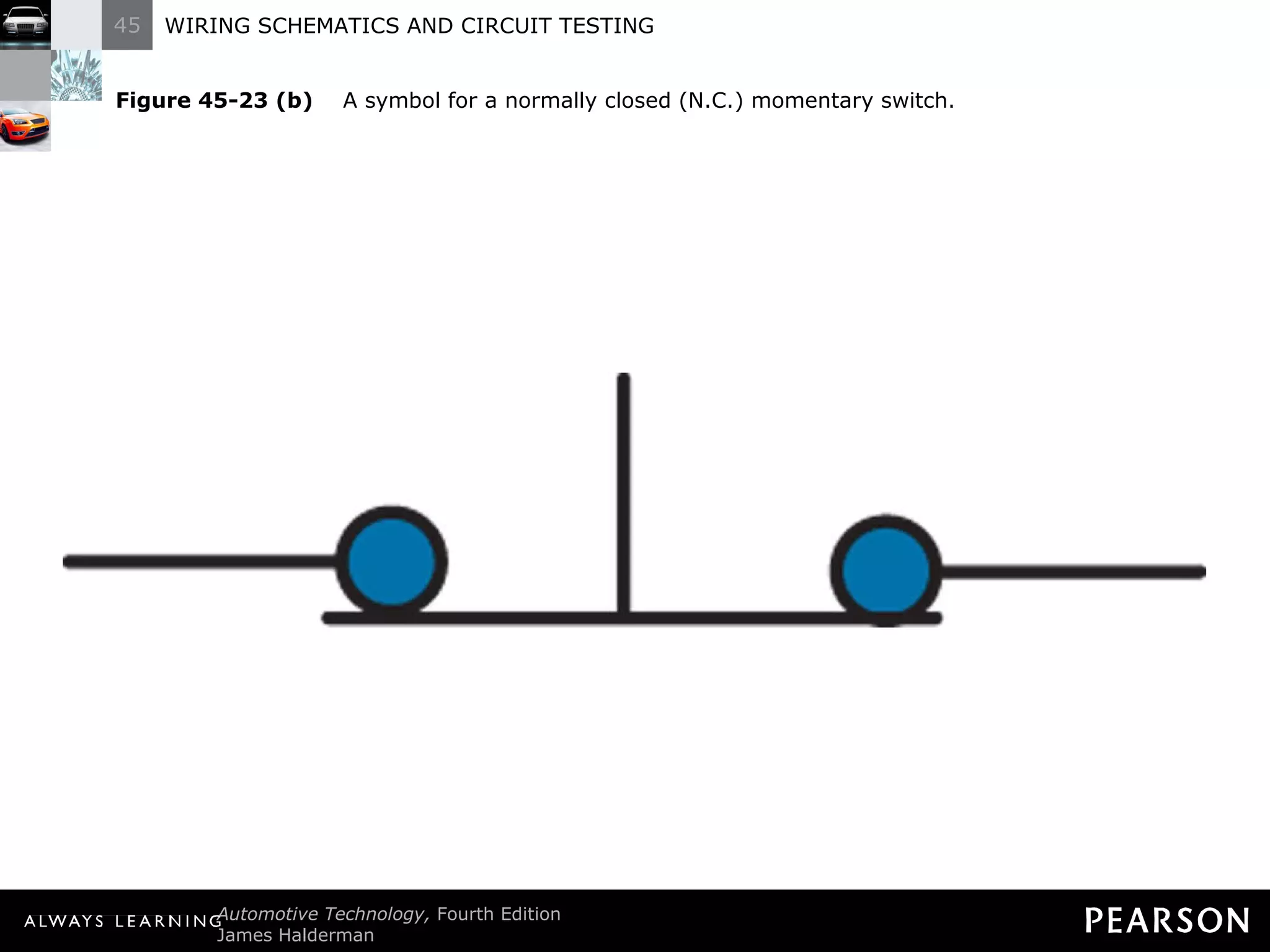

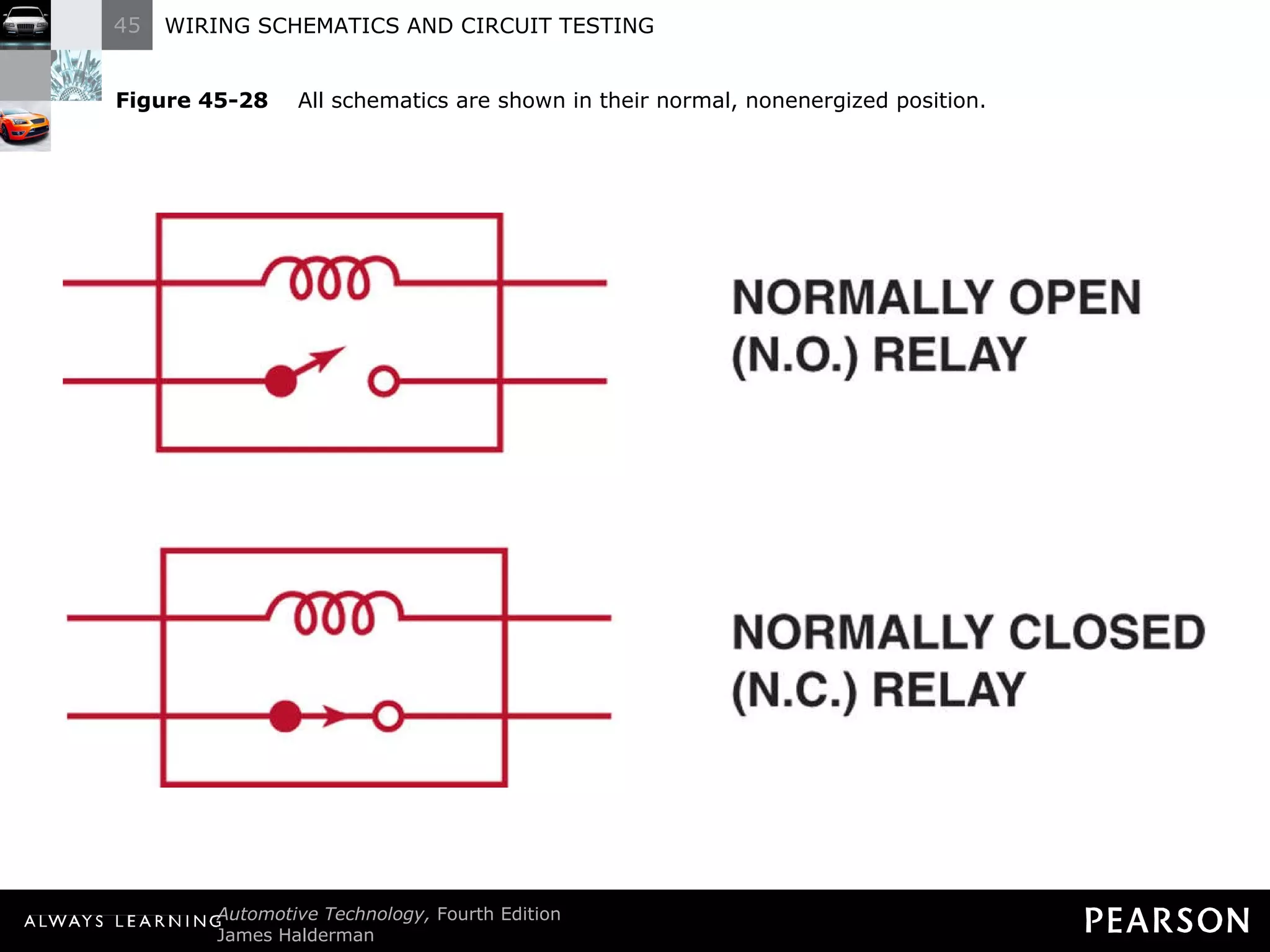

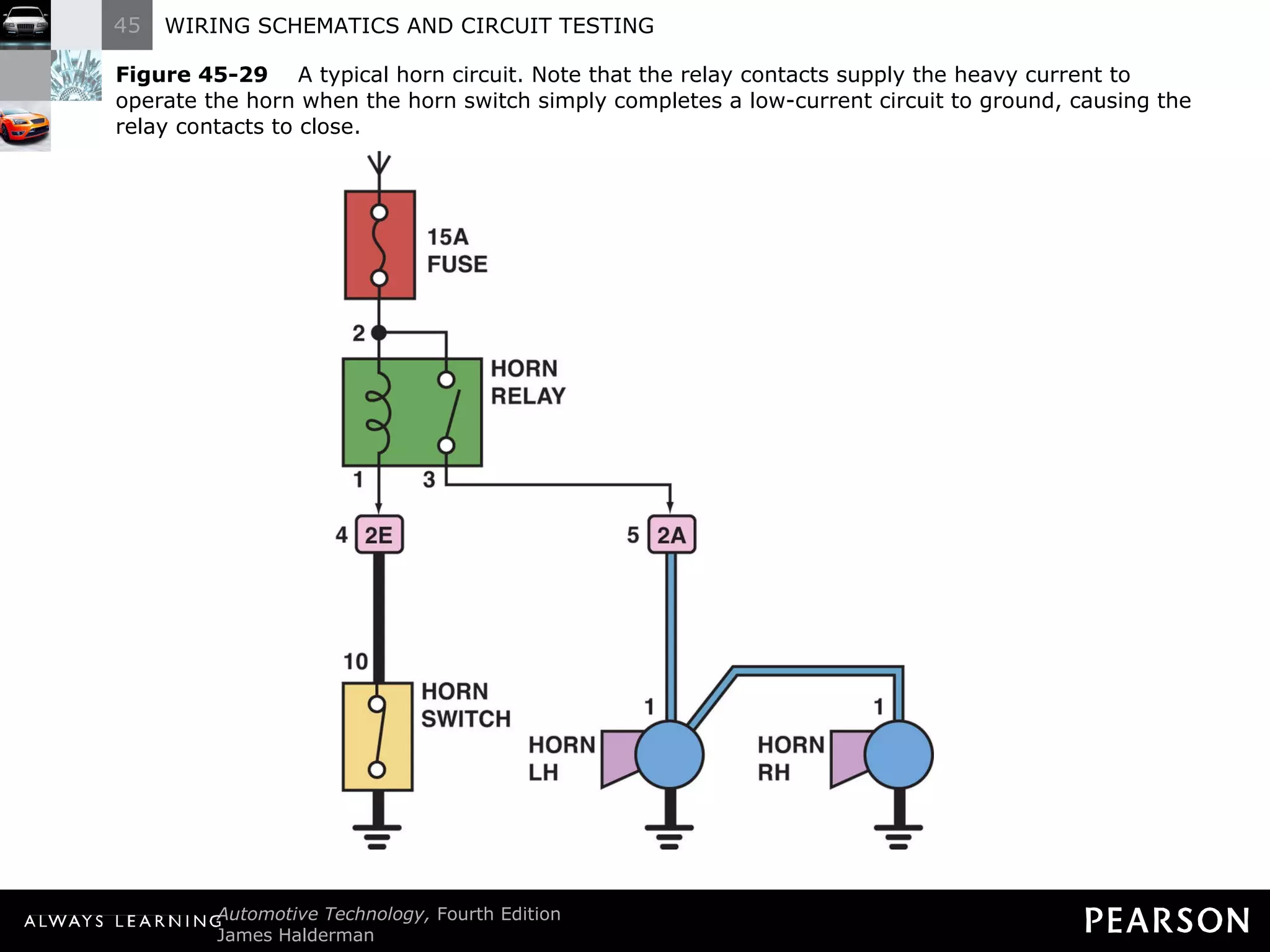

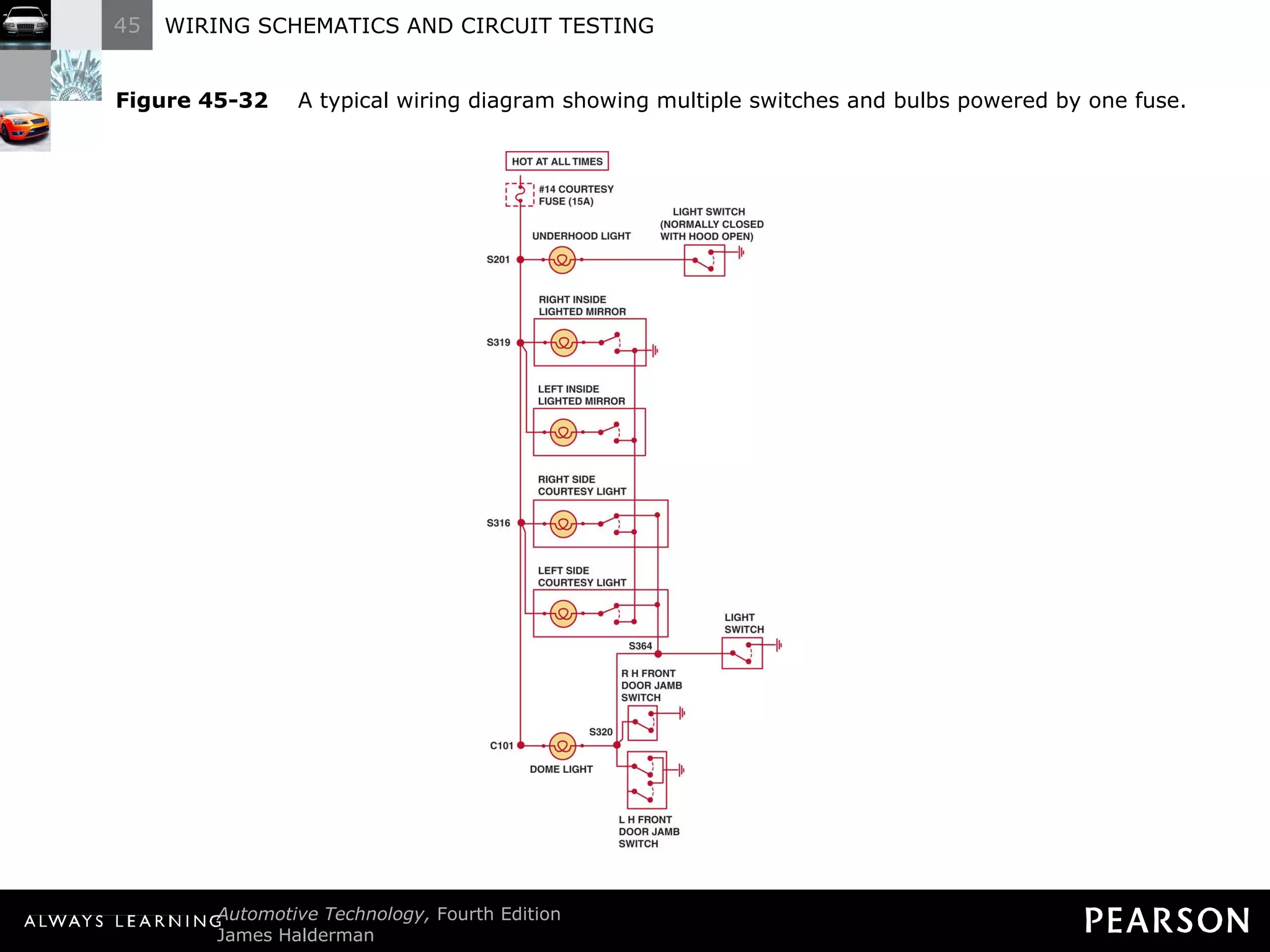

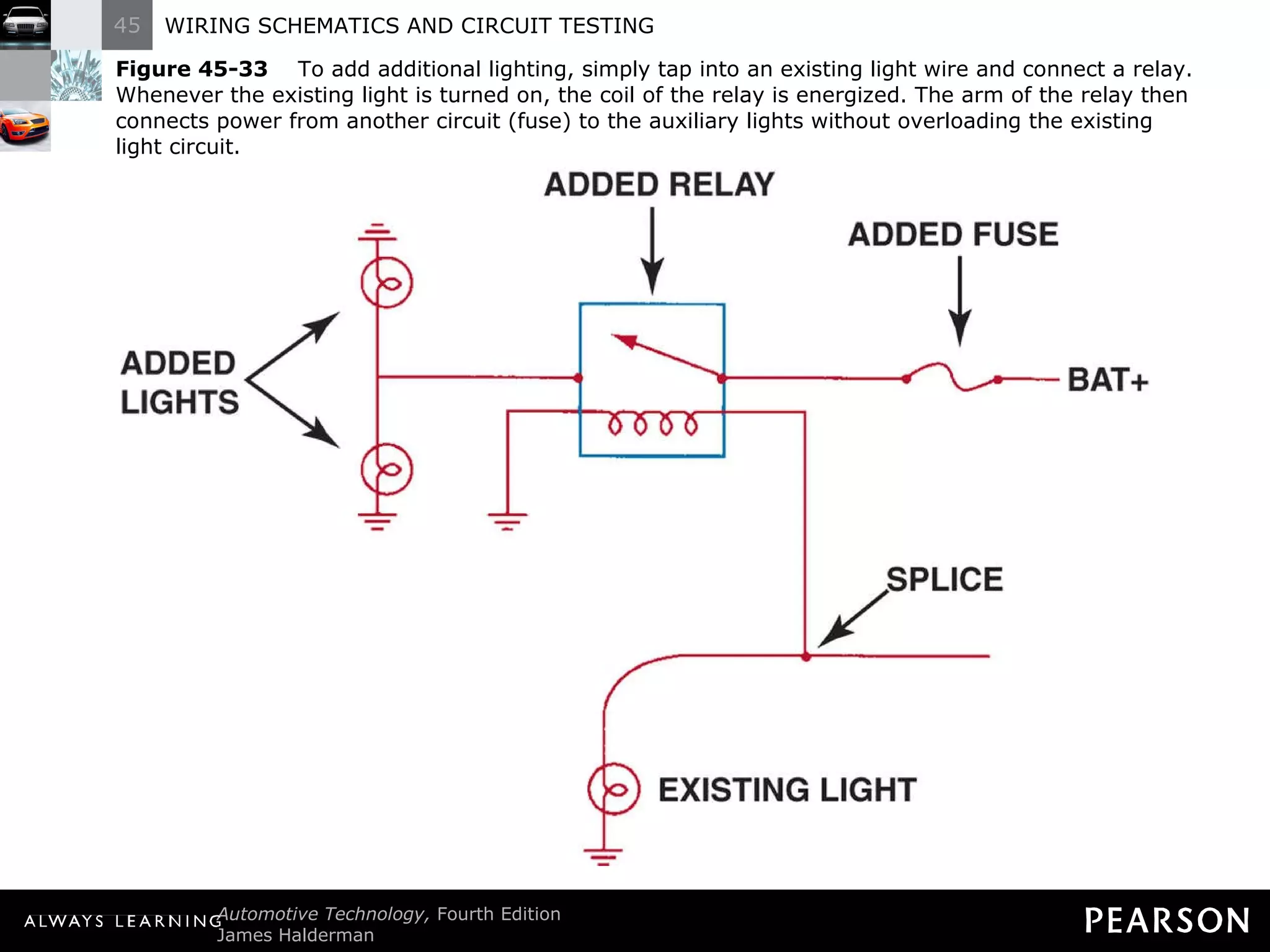

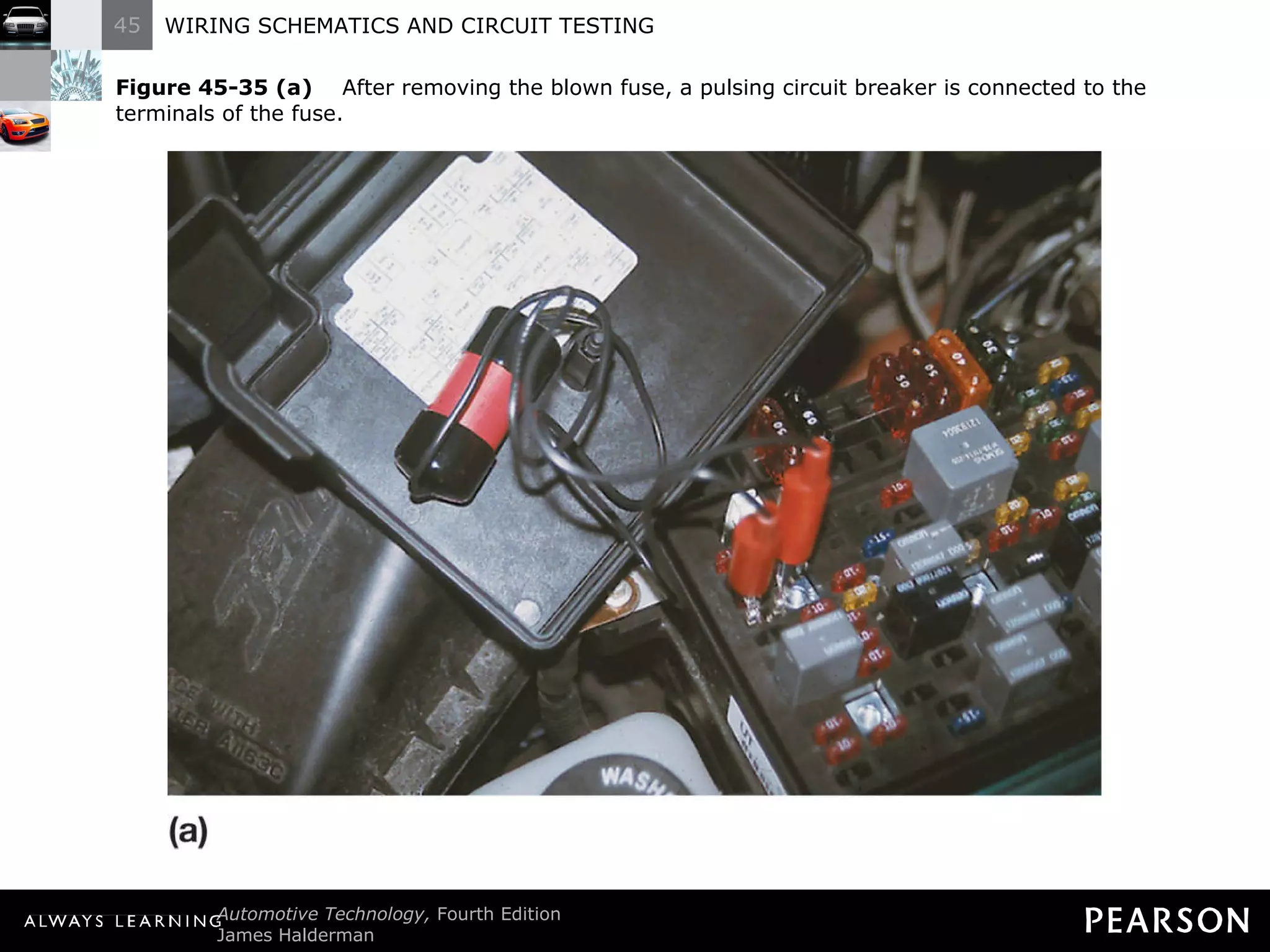

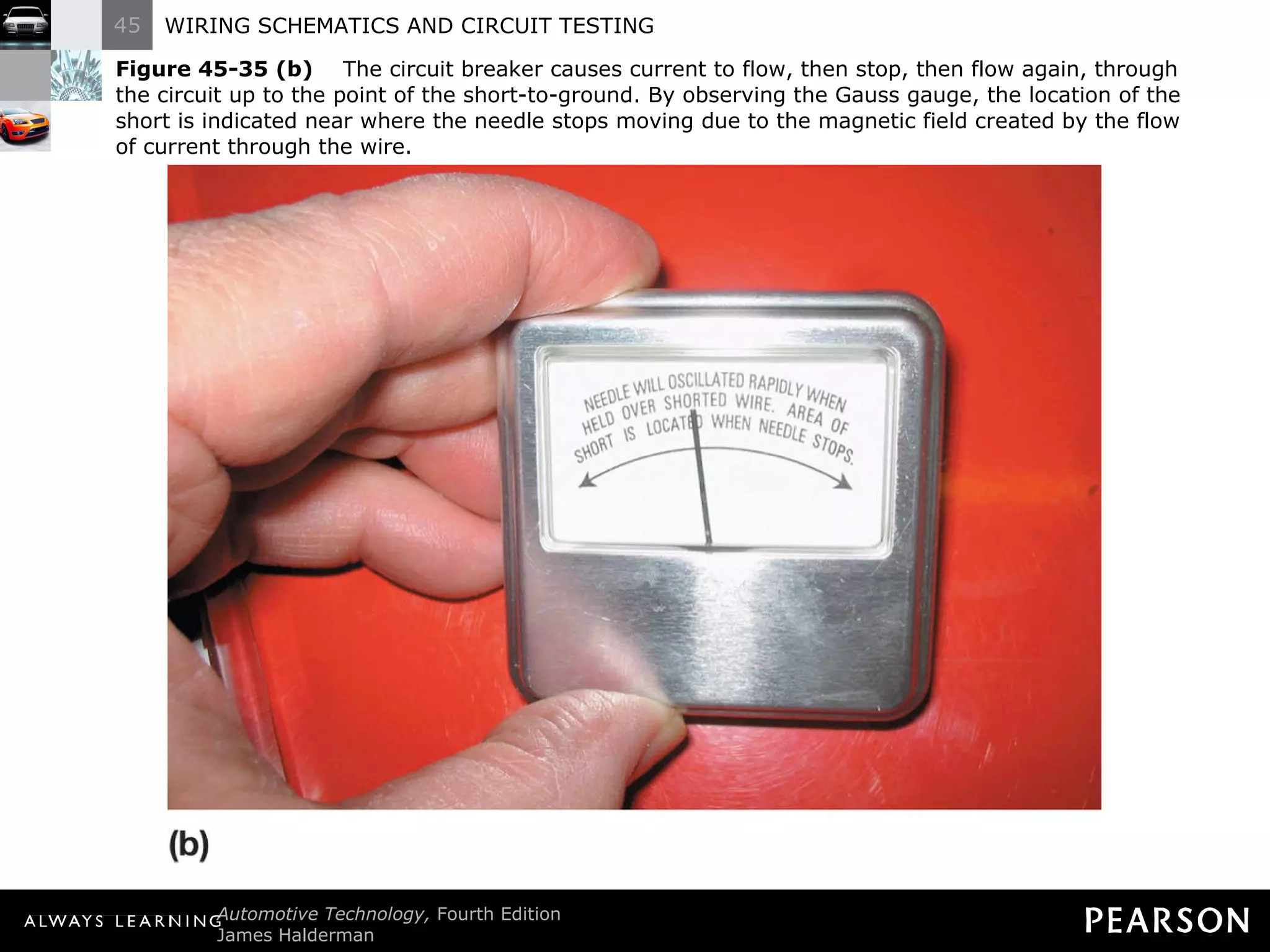

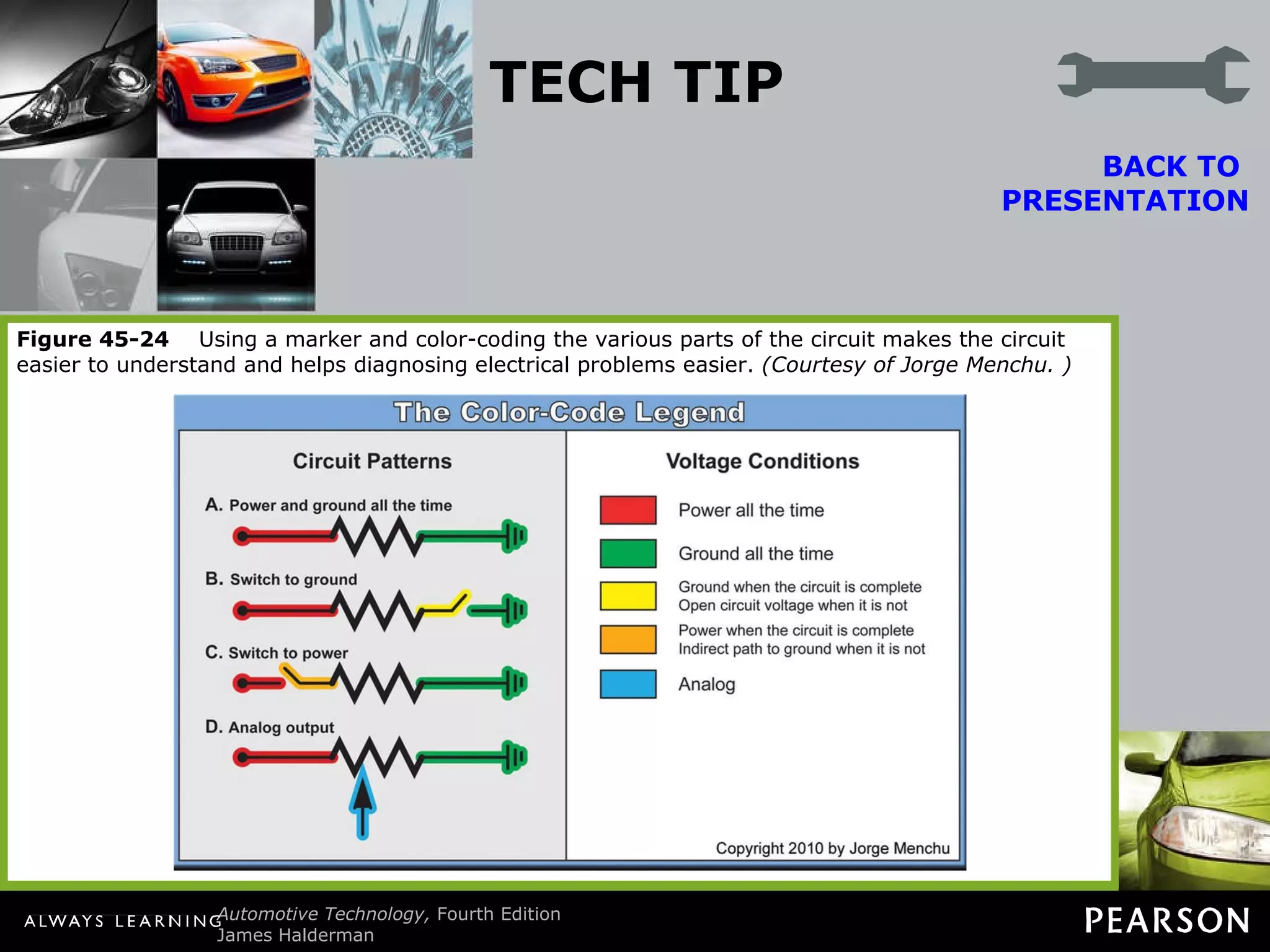

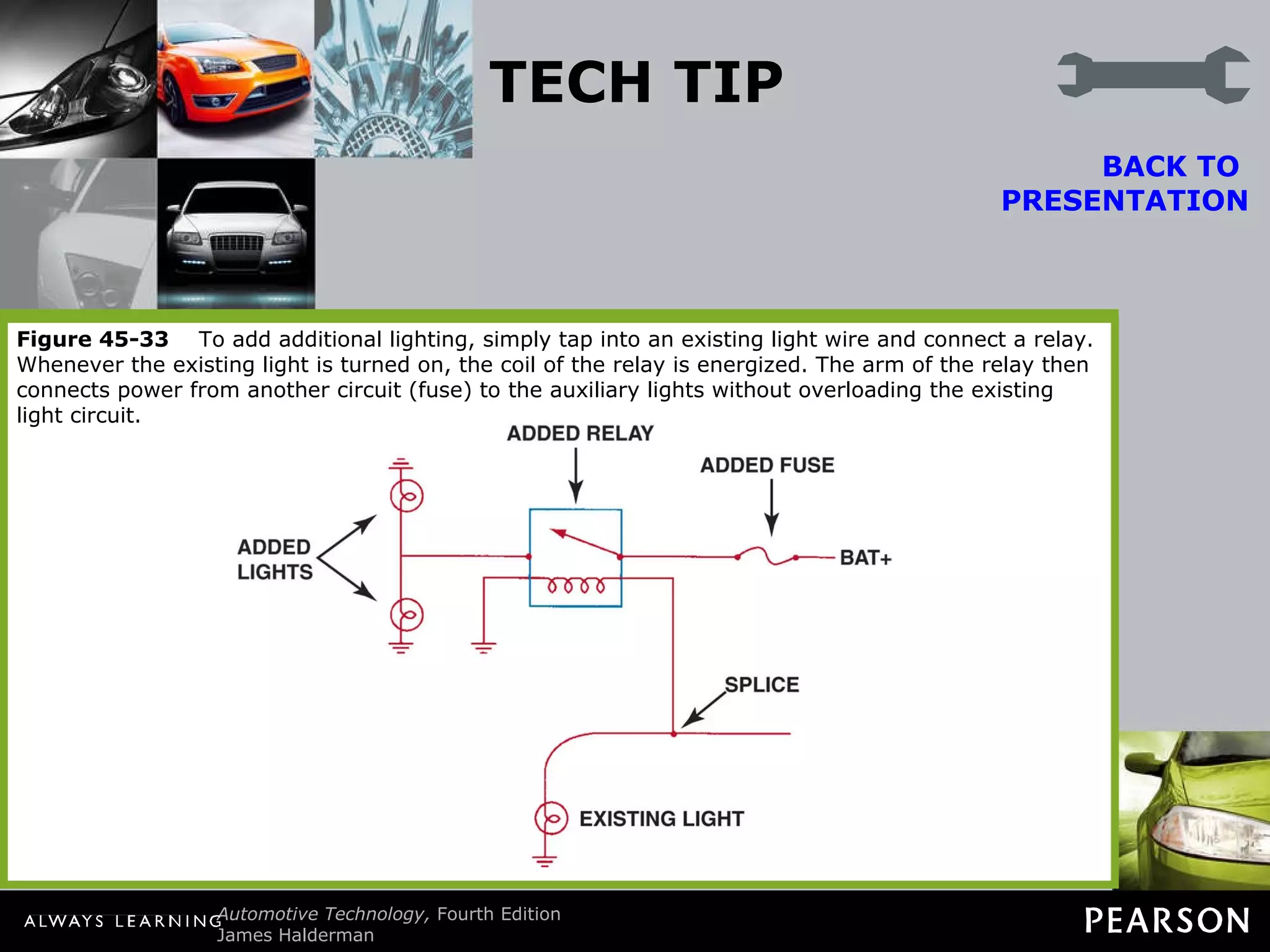

The document discusses wiring schematics and circuit testing. It provides information on interpreting wiring schematics, including that they use symbols to represent components and wires. It describes the elements typically included in wiring schematics such as power-side wiring, connectors, wire size, color and trace color. Common symbols used in automotive wiring diagrams are also explained, such as those representing batteries, wiring, electrical components, switches and other symbols.