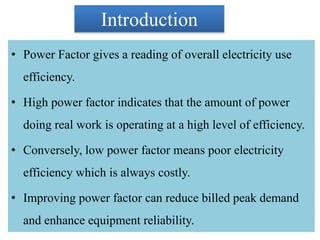

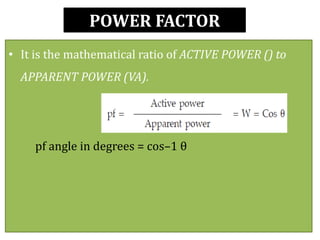

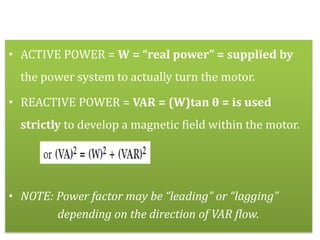

This document discusses power factor and methods for improving it. It defines power factor as the ratio of active power to apparent power. Low power factor is caused by inductive devices and indicates inefficient electricity use. Correcting power factor through capacitors can provide benefits like increased plant capacity and reduced utility charges. Capacitors work by opposing inductive lagging current. They can be installed at individual equipment, equipment groups, or at the main service, with various tradeoffs to consider. Harmonic distortion from devices like variable speed drives can also impact power quality if not properly addressed.