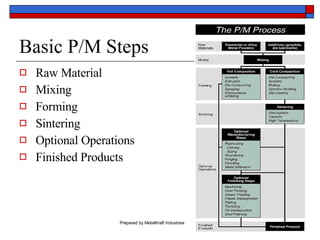

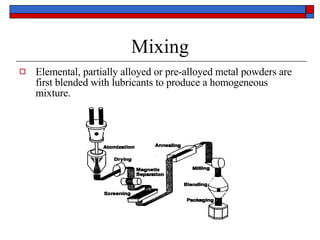

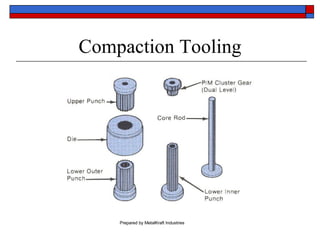

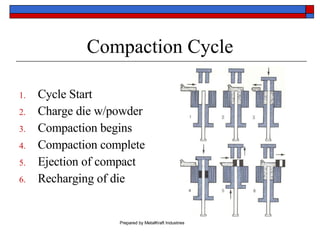

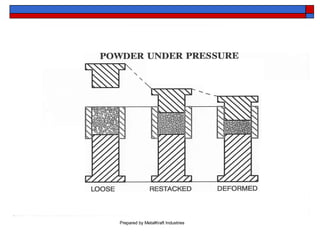

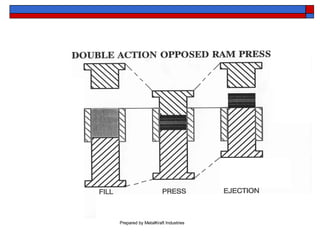

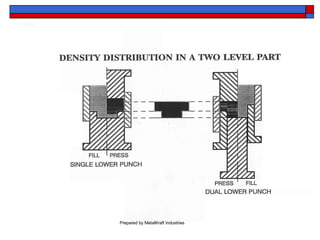

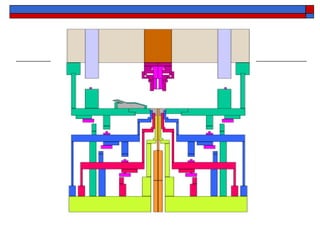

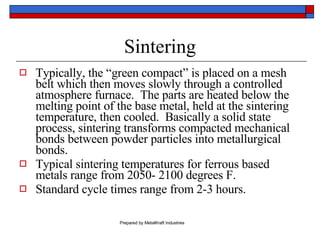

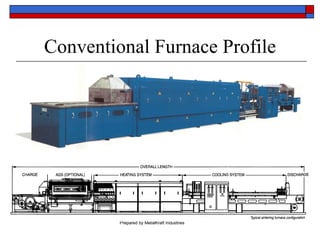

Powdered metallurgy is a highly developed manufacturing method that involves mixing metal powders, compacting them into a shape using dies, and sintering the compact to form metallurgical bonds. It is a chipless process that uses 97% of the starting material and offers advantages like close tolerances, complex shapes, repeatability, and being cost effective. The basic steps are mixing powders, compacting them into a green compact, and sintering to form bonds between particles.