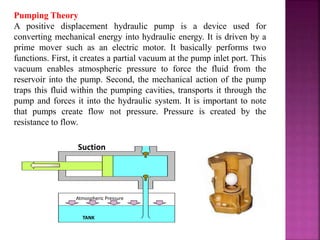

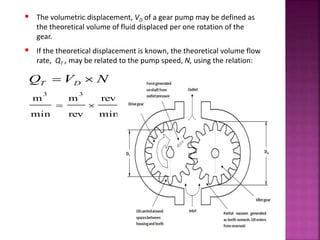

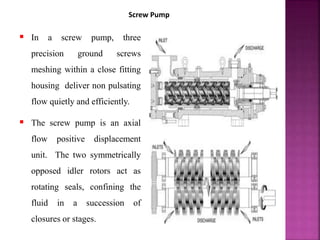

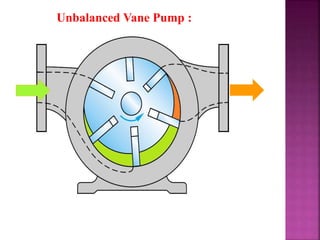

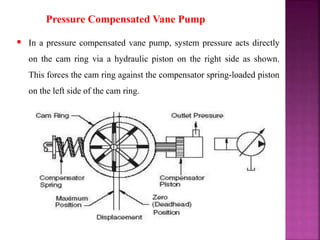

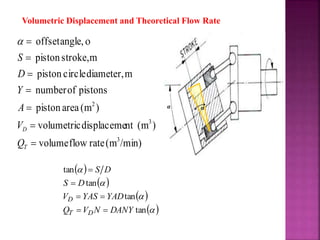

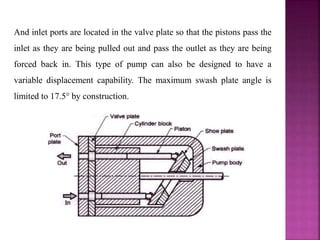

This document discusses hydraulic pumps used in industry. It begins by listing learning objectives related to classifying pumps, explaining their workings, and evaluating performance. It then defines the functions of pumps in converting mechanical to hydraulic energy. Pumps are classified as positive displacement or non-positive displacement, based on constant/variable delivery, and rotary/reciprocating motion. Key differences between these types are outlined. Specific pump types like gear, vane and piston are described in more detail regarding their construction, advantages, and uses.