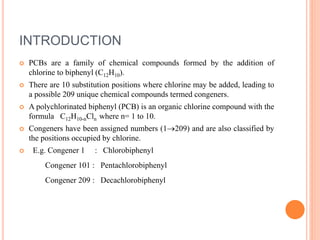

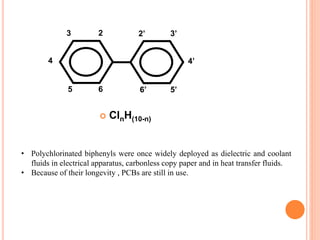

Polychlorinated biphenyls (PCBs) are synthetic chemicals formed by adding chlorine to biphenyl, with 209 potential unique compounds. Widely used until they were banned in 1976 due to their carcinogenic nature and harmful health effects, PCBs remain in the environment and can bioaccumulate in organisms. Various incidents have highlighted the dangers of PCBs in food production and electrical equipment, leading to significant health advisories and regulatory measures.