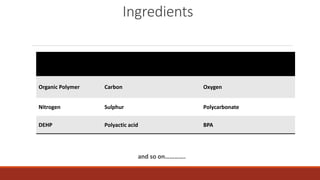

The document discusses the use of plastic as a construction material, highlighting its advantages like durability, cost-effectiveness, and recyclability. It covers various applications of plastics in construction, including flooring, roofing, and road construction, while also addressing potential environmental concerns, such as microplastic pollution. The future scope mentions innovative uses of recycled plastic in housing, emphasizing sustainability and structural benefits.