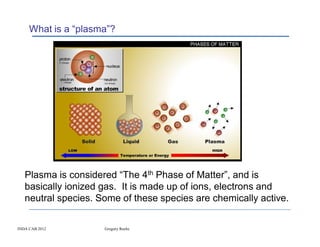

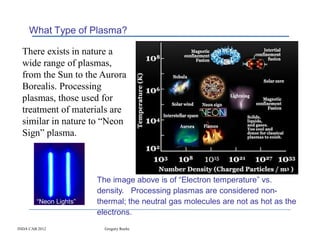

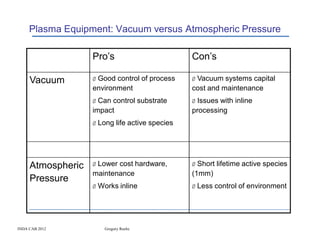

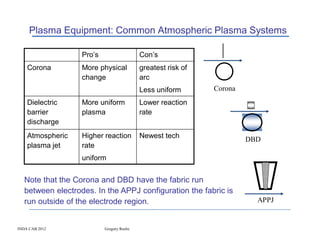

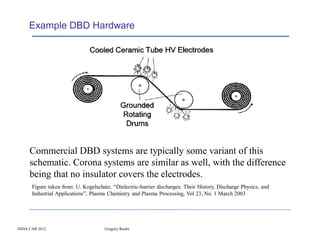

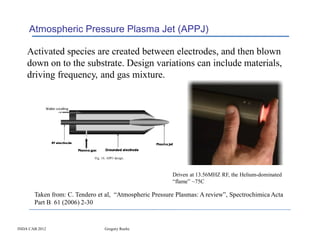

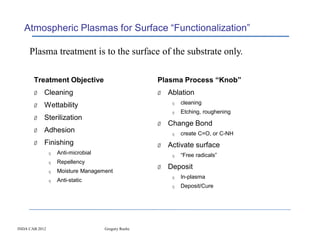

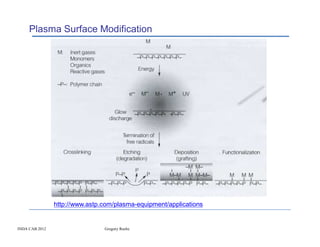

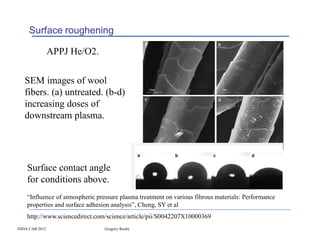

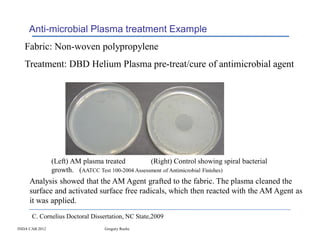

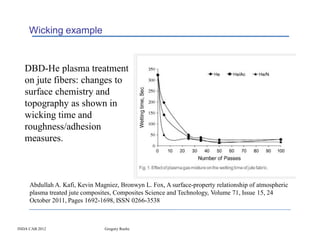

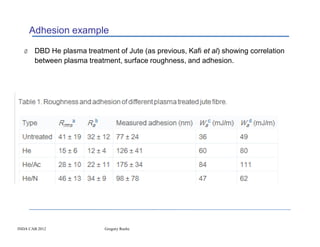

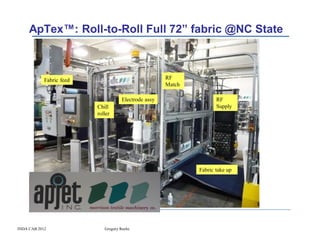

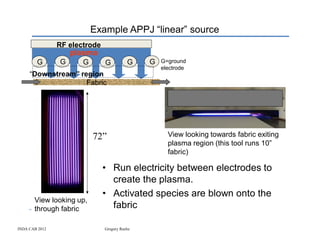

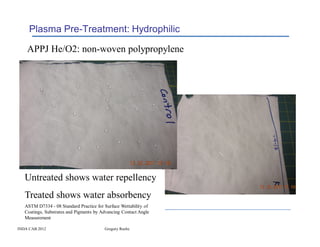

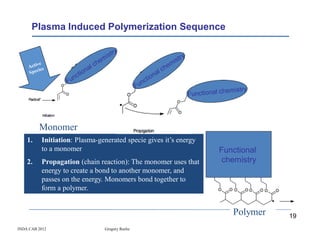

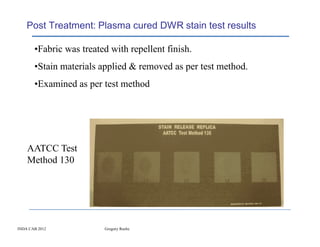

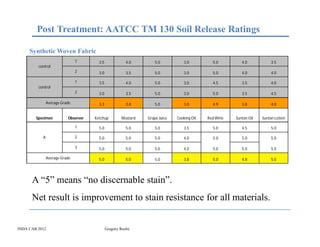

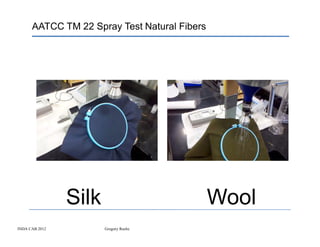

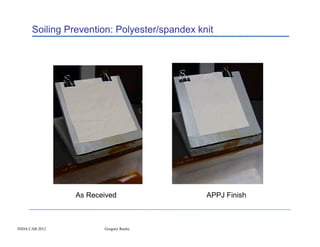

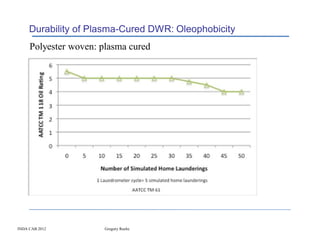

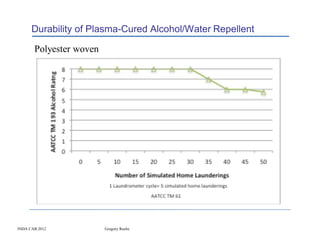

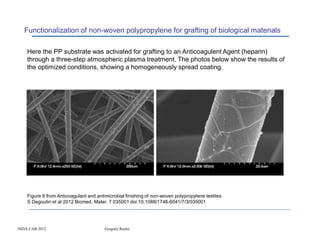

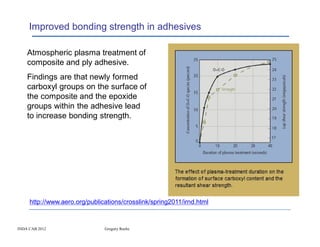

Recent Advances in Atmospheric Plasma Treatment of Textiles discusses how atmospheric plasma treatment is a new technology for surface finishing and pretreatments of textiles. It can be used on a wide range of materials, both woven and non-woven, and provides benefits like no waste water generation and effective processing costs. The document outlines different types of plasma equipment, examples of fabric treatments including cleaning and imparting hydrophilicity, and potential future applications of plasma treatment like adding functionality to fabrics.