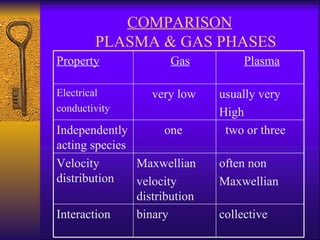

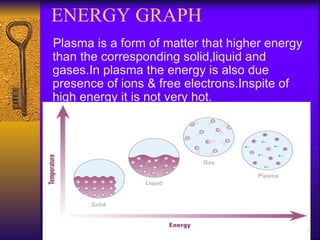

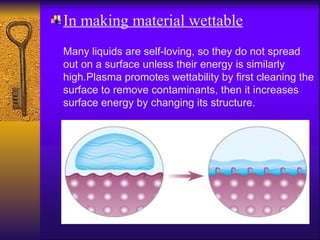

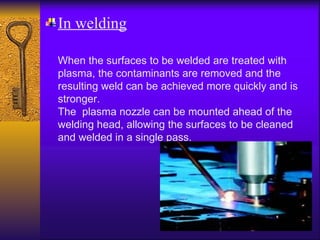

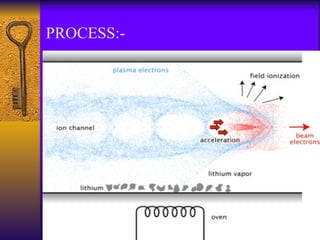

Plasma is the fourth state of matter and consists of ionized gas containing positive ions and free electrons. Plasma makes up over 90% of the visible universe and can be generated by heating a gas or subjecting it to a strong electromagnetic field. Plasma has unique properties compared to solids, liquids, and gases such as being electrically conductive and interacting collectively. Plasma technology has various applications including surface cleaning and functionalization, welding, lighting, and plasma displays. Plasma treatment can improve properties like wettability and adhesion without using solvents.