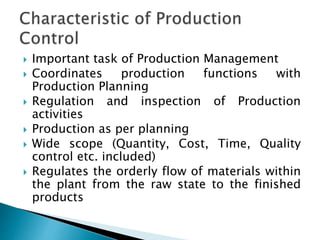

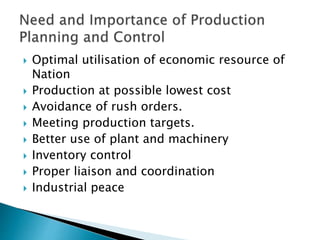

Production control involves implementing production plans to ensure operations occur as scheduled. It coordinates manufacturing activities to meet schedules with optimal efficiency. Production control regulates the flow of materials through the production process from raw materials to finished goods. It aims to achieve production goals, ensure smooth operations by removing issues, and optimize resource use while minimizing costs and maintaining quality. Production planning and control are interrelated functions that are impossible without each other.