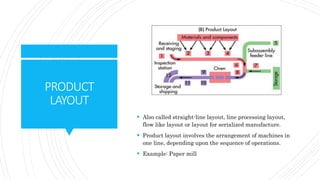

The document discusses various types of plant layouts including product-based, process-based, fixed position, flexible manufacturing systems, and cellular manufacturing, highlighting their advantages and disadvantages. It outlines how each layout affects production efficiency, supervision, and capital investment. Additionally, the document covers aspects of business promotion, company registration, capital subscription, and factors influencing optimal plant location.