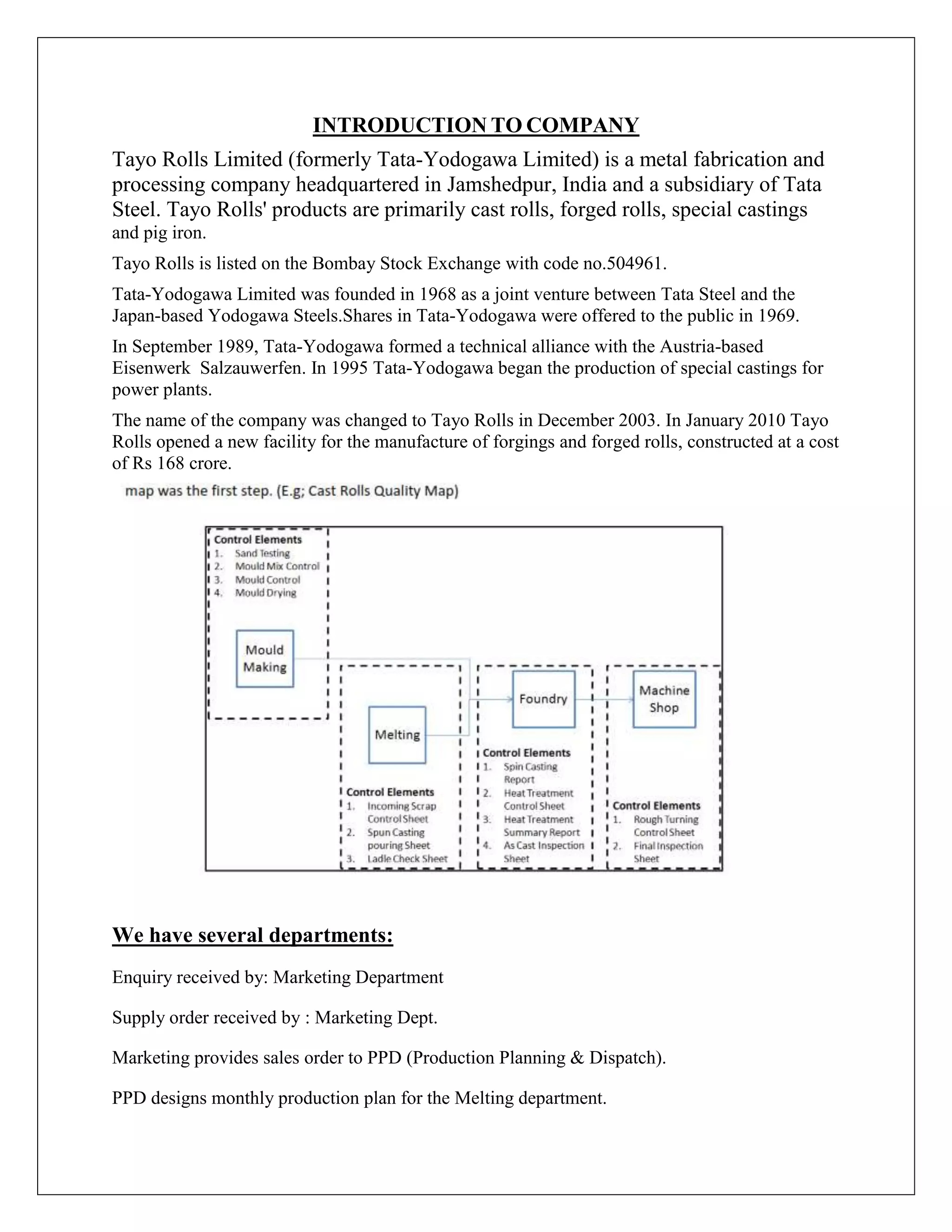

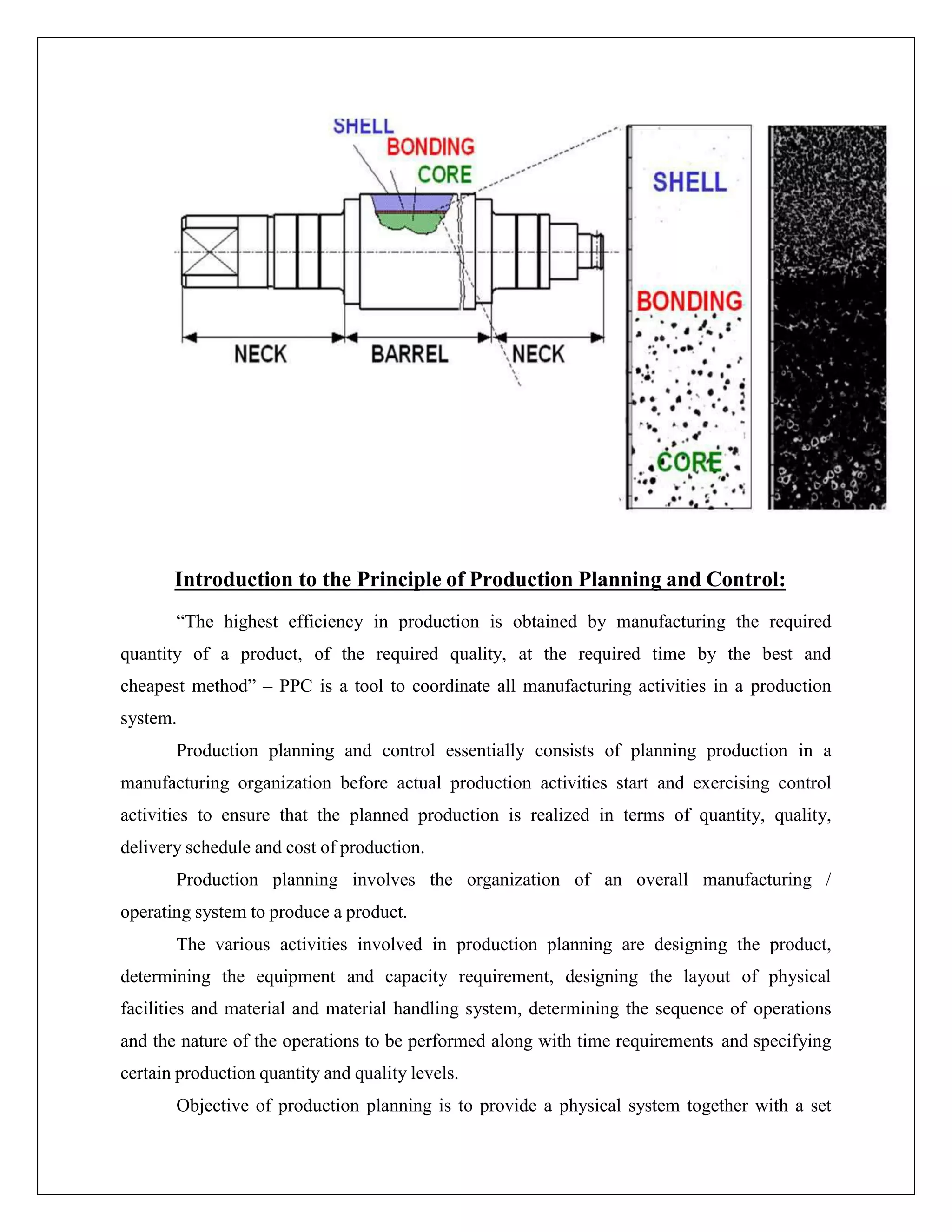

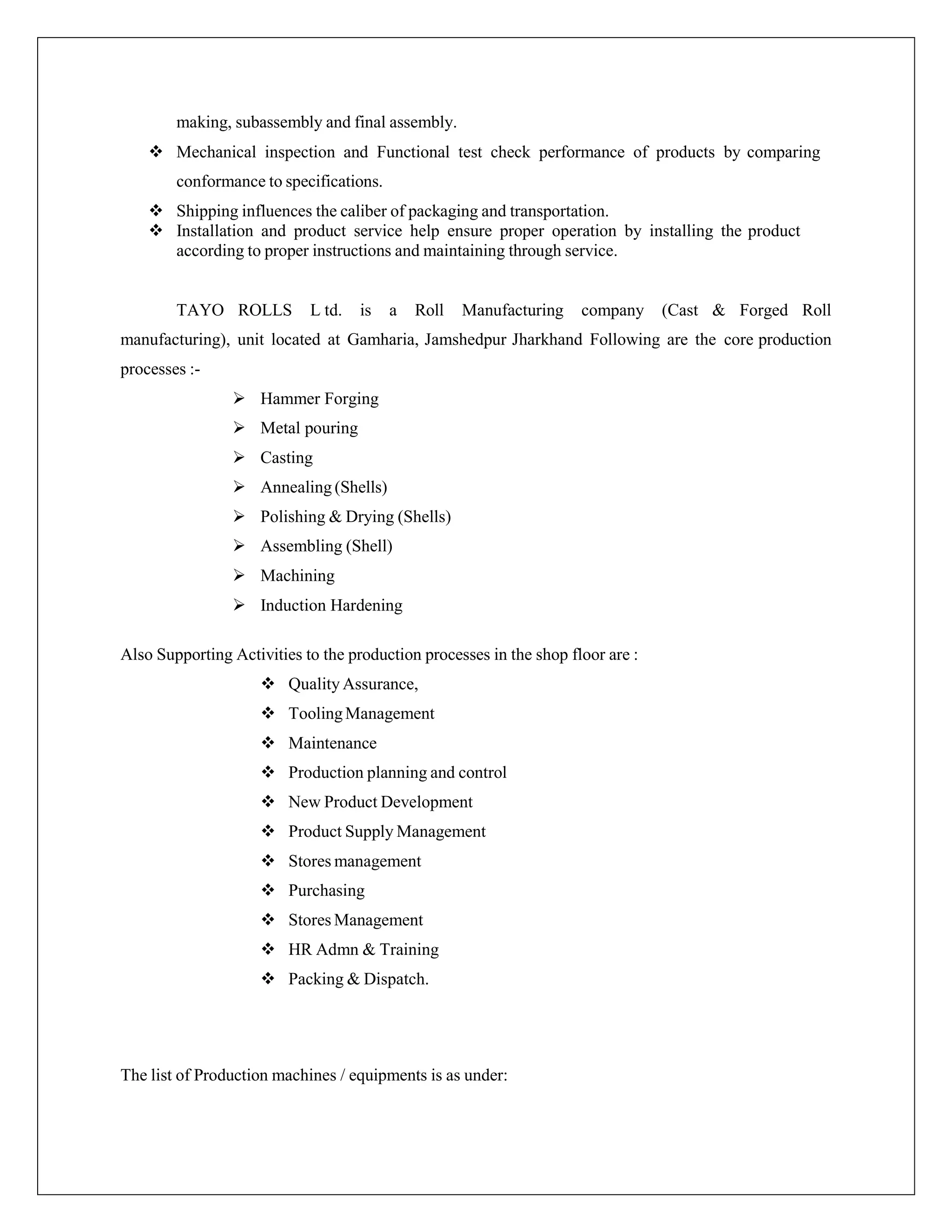

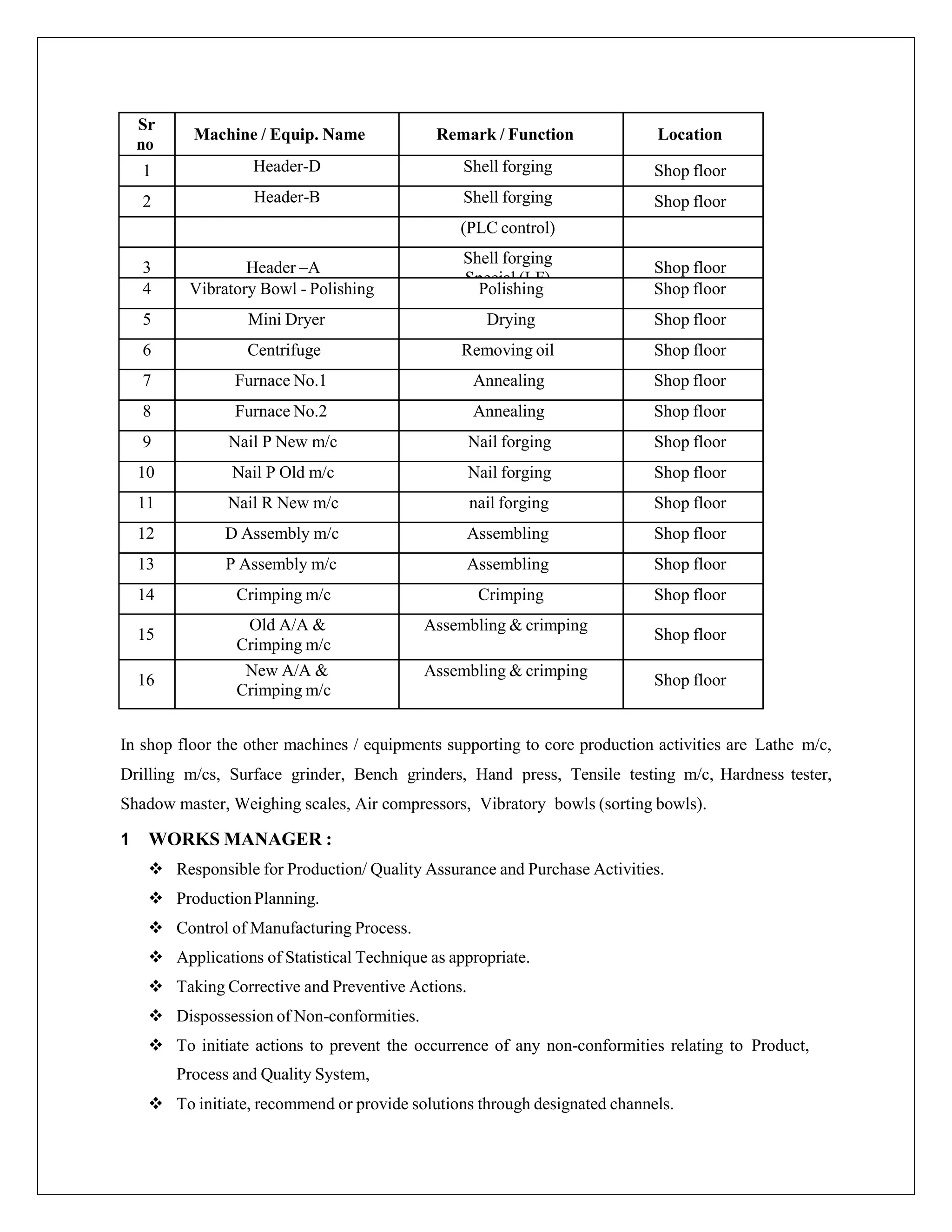

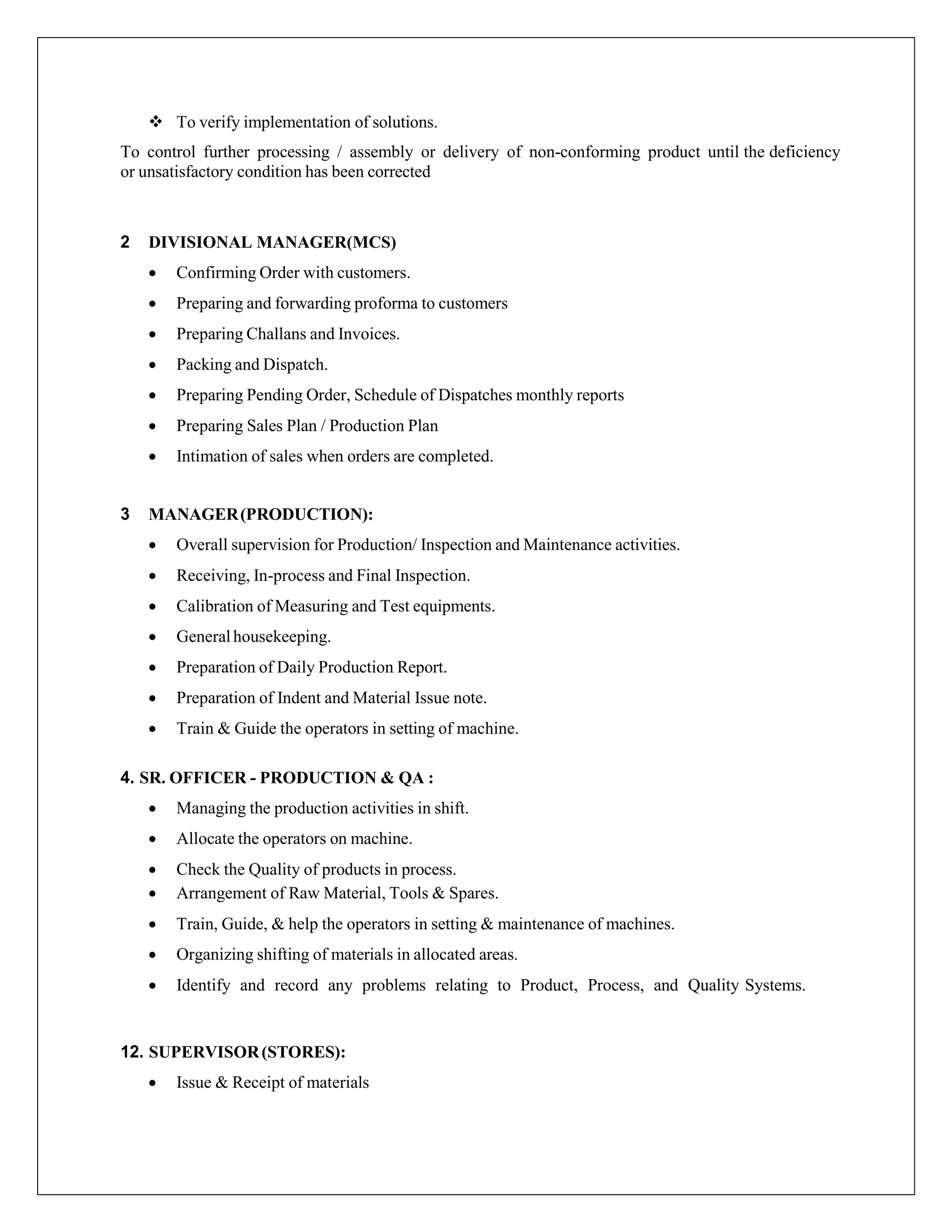

The document provides details about Tayo Rolls Ltd, including its production planning process. It discusses [1] the company's various departments involved in production planning, [2] factors that affect machine shop production planning such as product mix and cycle times, and [3] the objectives and key elements of an effective production planning and control system.