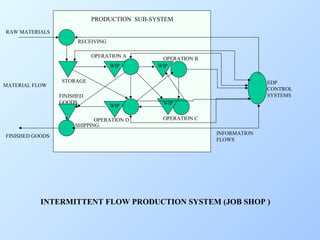

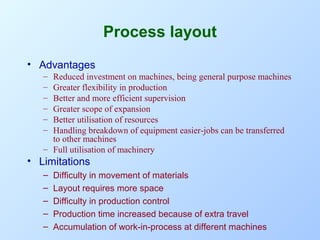

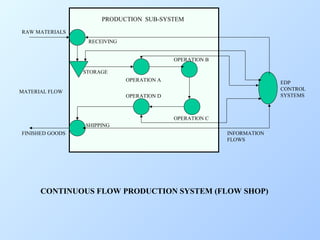

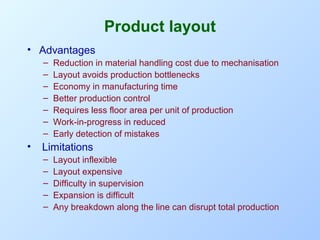

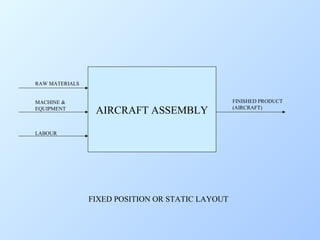

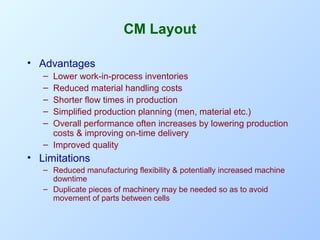

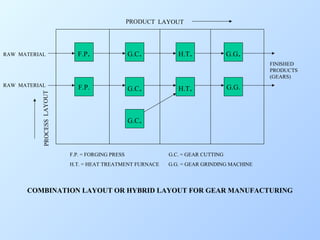

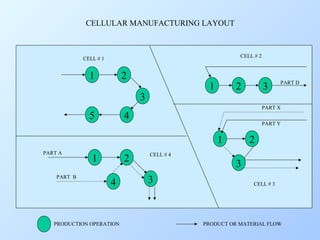

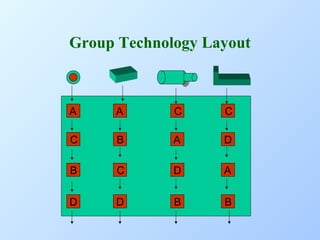

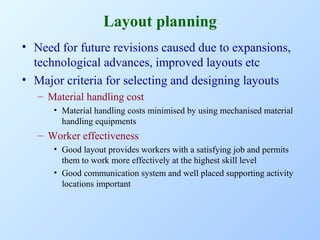

This document discusses factors to consider when selecting a location and designing the layout for a manufacturing plant. It outlines key steps in the plant location process, including selecting a country, region, locality, and exact site based on availability of resources. The document then covers different types of plant layouts like process, product, and cellular layouts and considerations for each. It also discusses factors that influence layout design like the type of product, workers, and machinery used. The overall goal of location and layout selection is to allow for efficient material and information flow at the lowest possible cost.