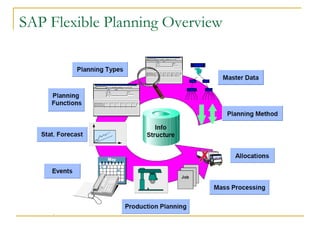

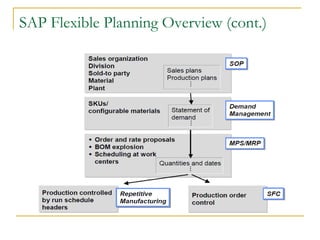

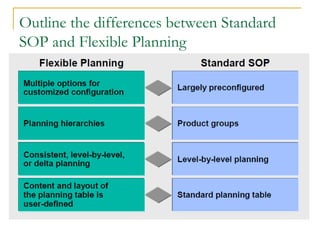

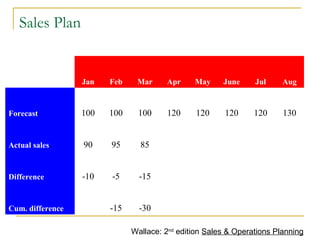

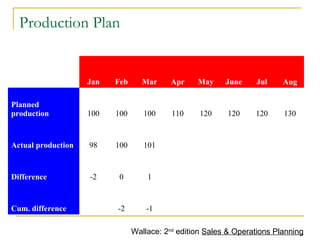

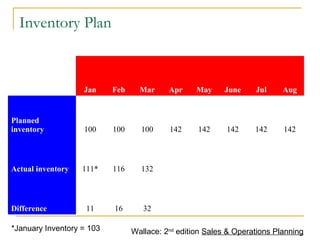

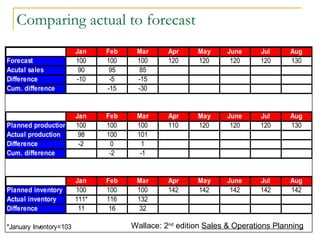

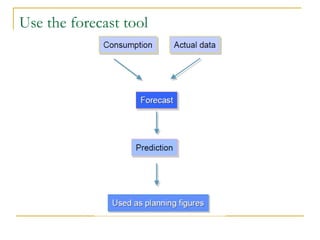

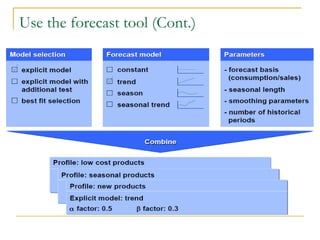

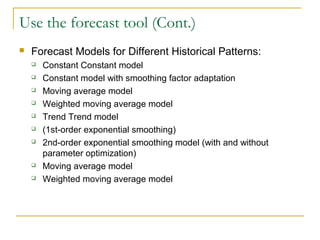

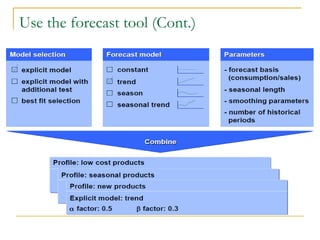

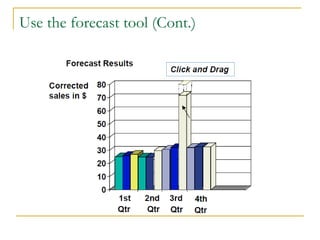

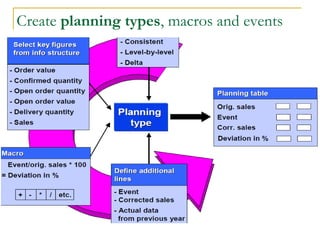

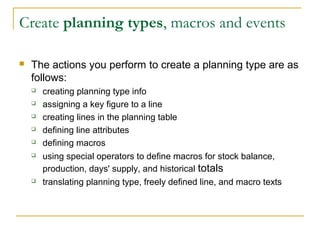

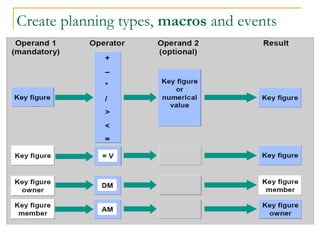

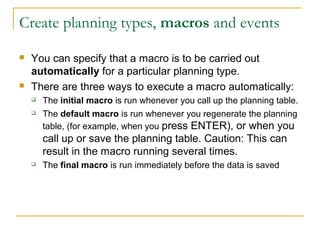

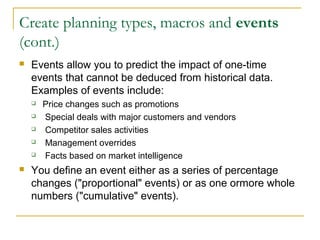

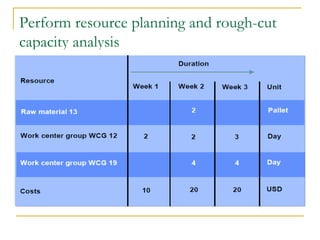

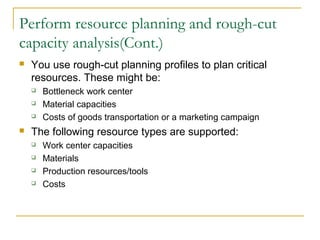

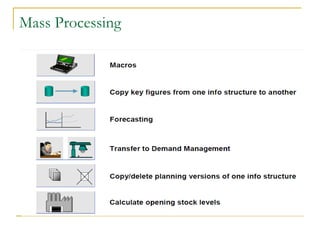

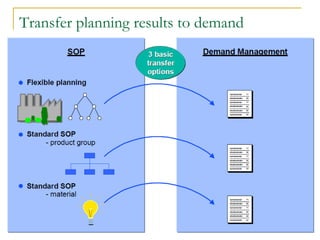

This document provides an overview and agenda for SAP Flexible Planning. It discusses the differences between standard SOP and flexible planning, how to create sales and production plans, use forecasting tools, create planning types and macros, perform resource planning and capacity analysis, use mass processing, and transfer planning results to demand management. The key topics covered include outlining the differences between standard SOP and flexible planning, comparing actual sales, production, and inventory to forecasts, defining events to predict impacts, planning critical resources like work centers, and transferring SOP data from flexible planning to demand management.