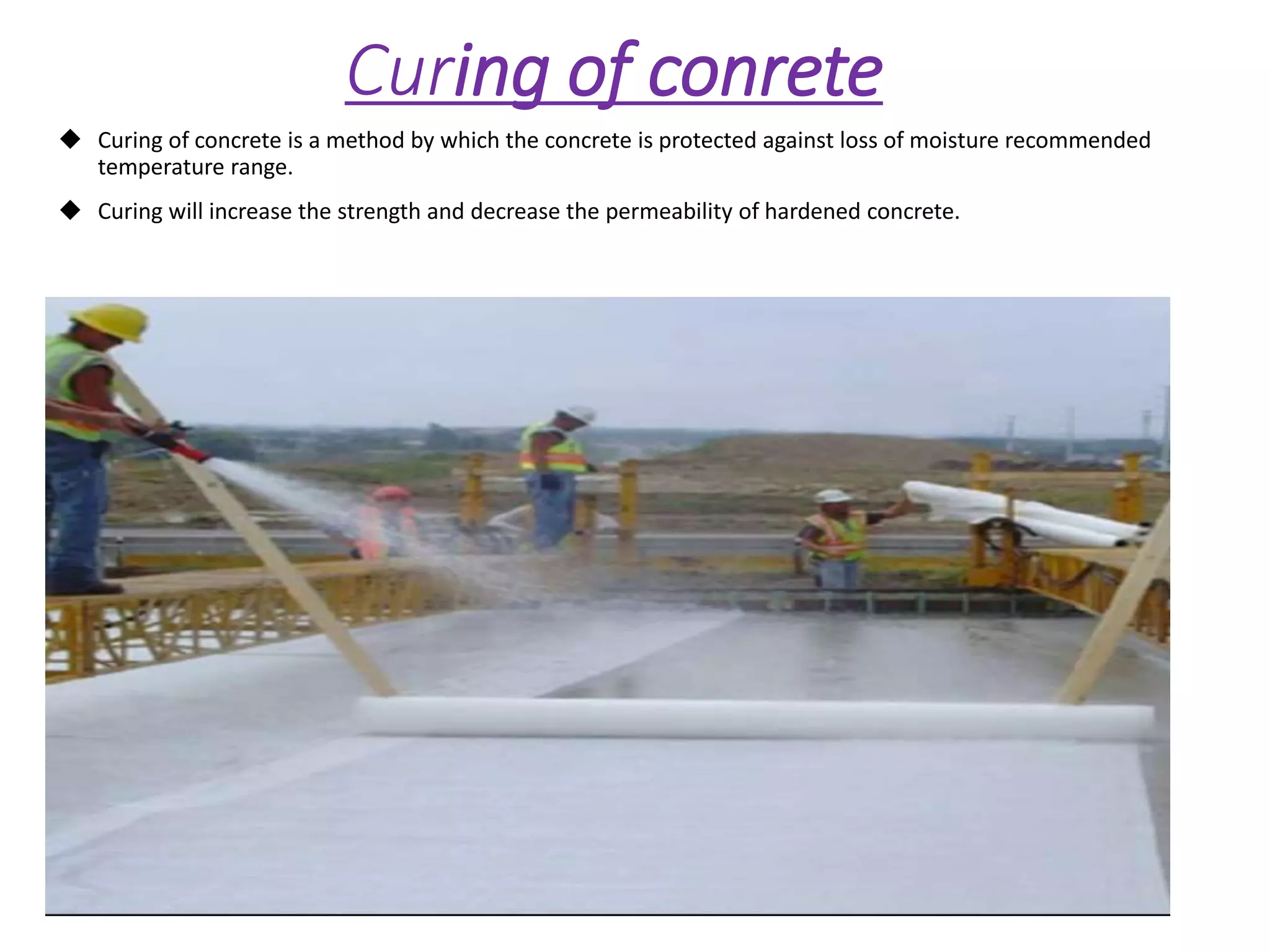

This document discusses curing of concrete. Curing involves protecting concrete from moisture loss to allow proper hydration and increase strength and durability. Proper curing methods include water curing, membrane curing, and heat curing. Water curing through immersion, ponding, or spraying provides continuous moisture. Membrane curing uses plastic sheets to reduce evaporation. Heat curing through steam or electricity can speed hydration in cold climates. Different curing methods maintain moisture to fully hydrate the concrete.