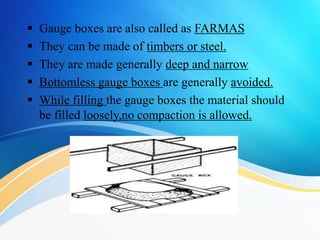

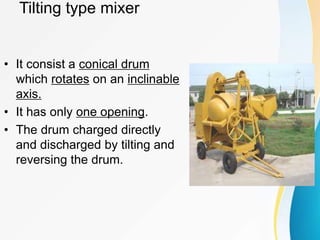

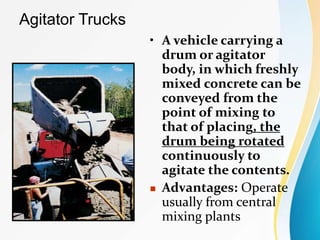

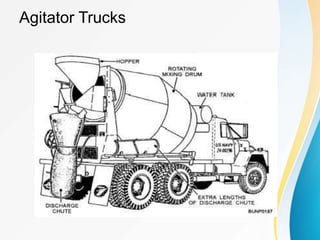

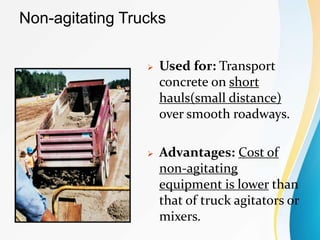

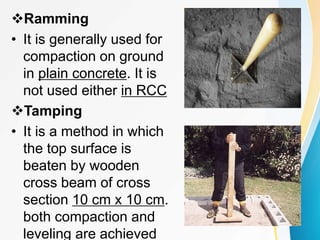

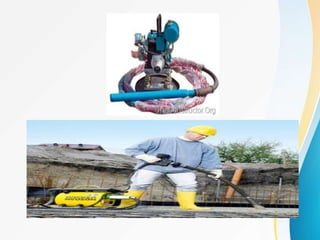

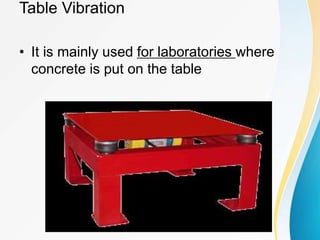

This document discusses various stages of manufacturing concrete, including batching, mixing, transporting, placing, compacting, curing, and finishing. It describes batching by volume or weight, mixing methods such as hand mixing or using stationary or ready mix concrete, transporting concrete using various equipment, and compacting concrete through hand or vibratory methods to remove air. The key stages and methods are outlined in detail with explanations and examples provided.