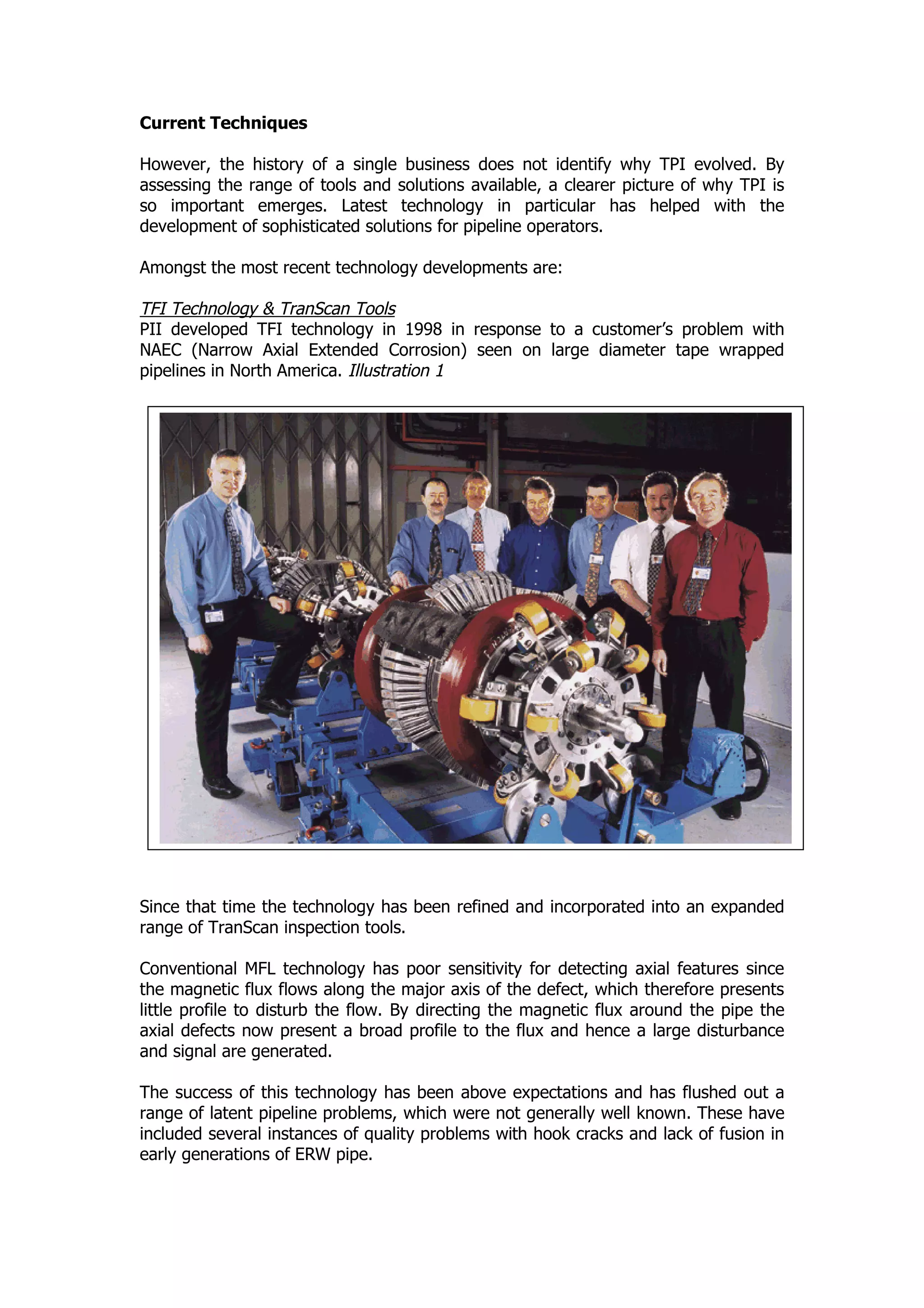

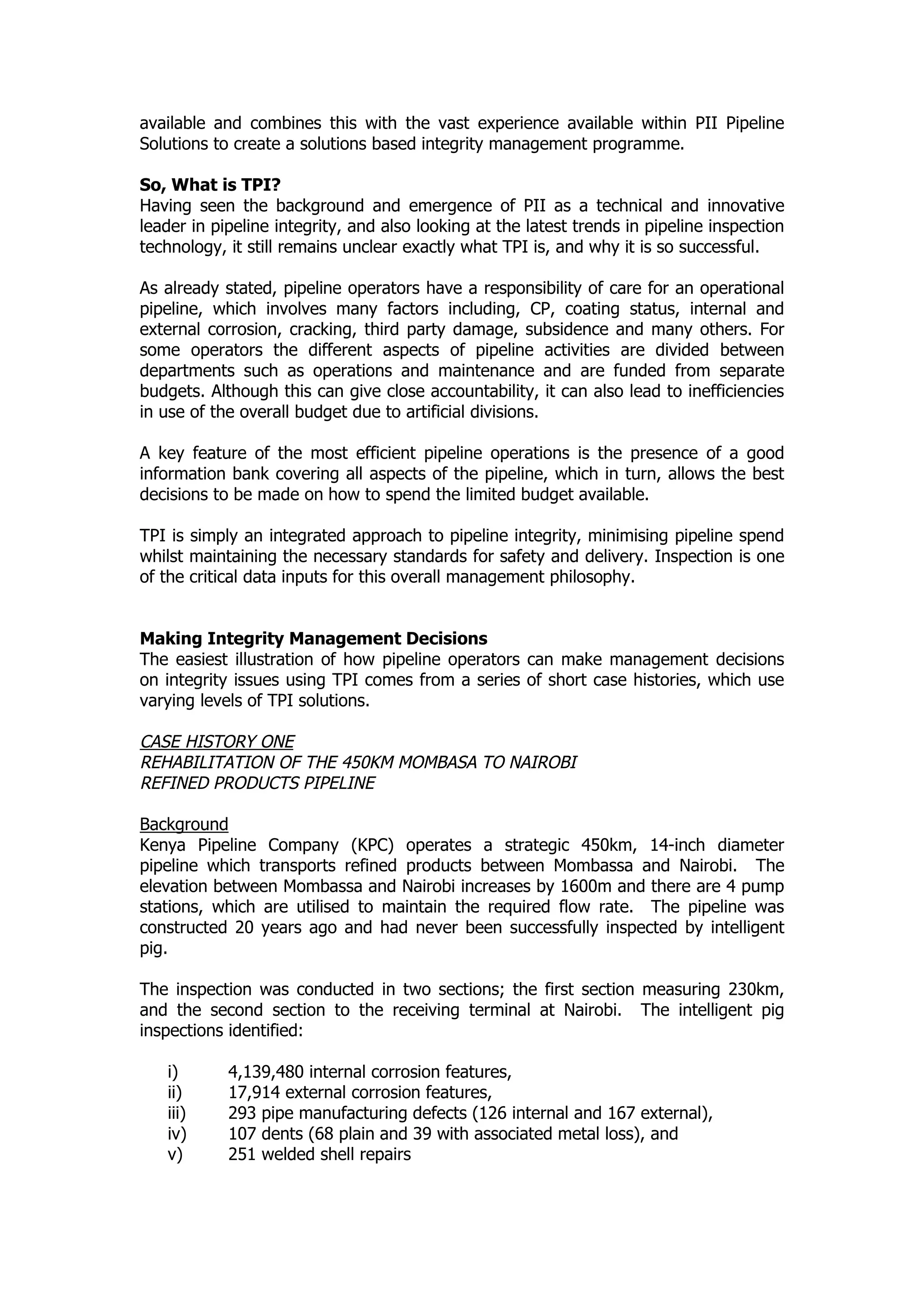

Pipelines deteriorate over time due to corrosion and fatigue, threatening their integrity. To manage this risk, operators have implemented inspection and maintenance programs using intelligent pigs to detect corrosion. These programs were limited until PII pioneered Total Pipeline Integrity solutions combining affordable technology, methodology, and expertise. The paper discusses the history of pipeline inspection technology advances pioneered by PII, from the first magnetic flux tool in the 1970s to current tools, enabling operators to effectively manage pipeline integrity.