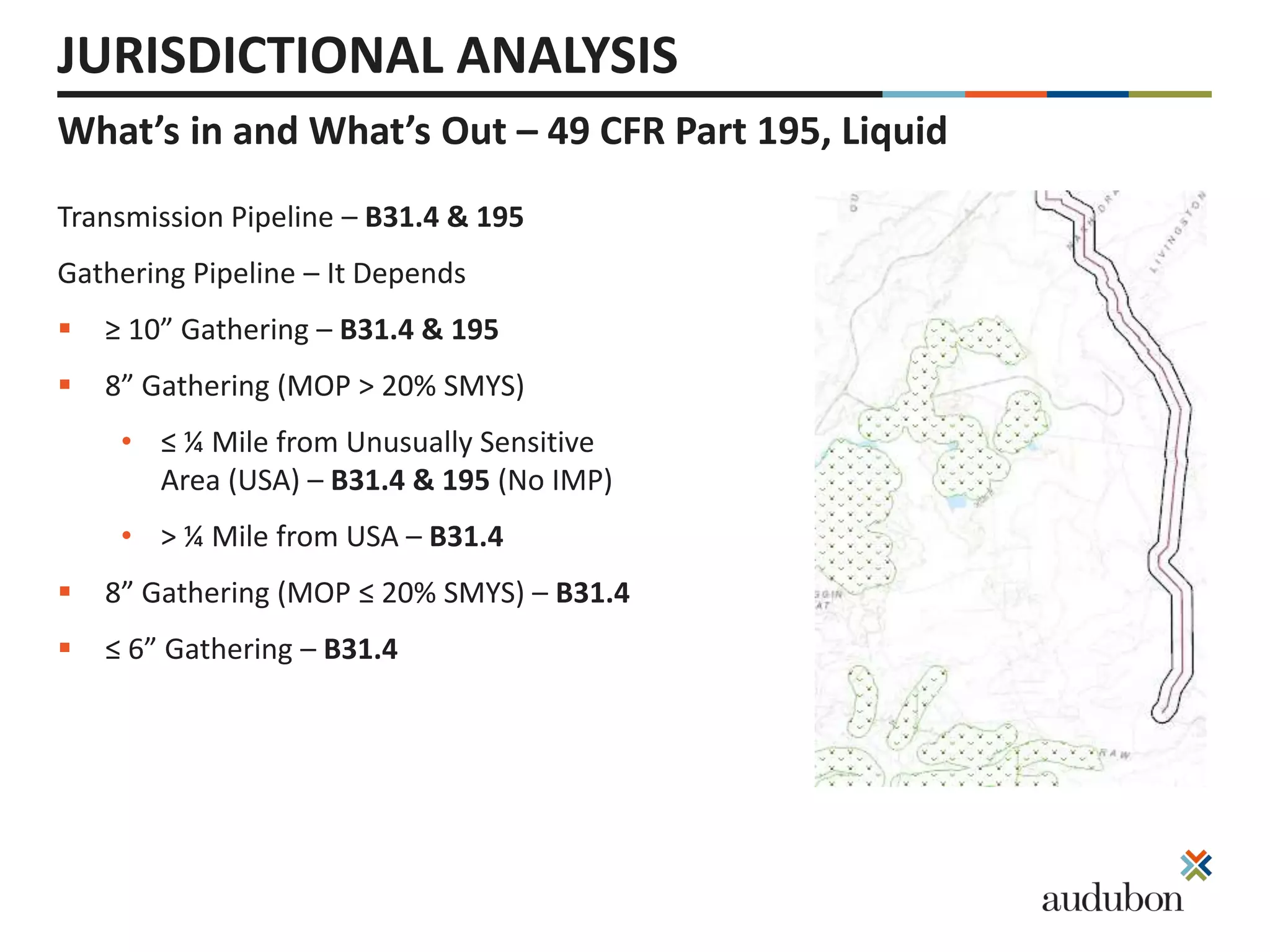

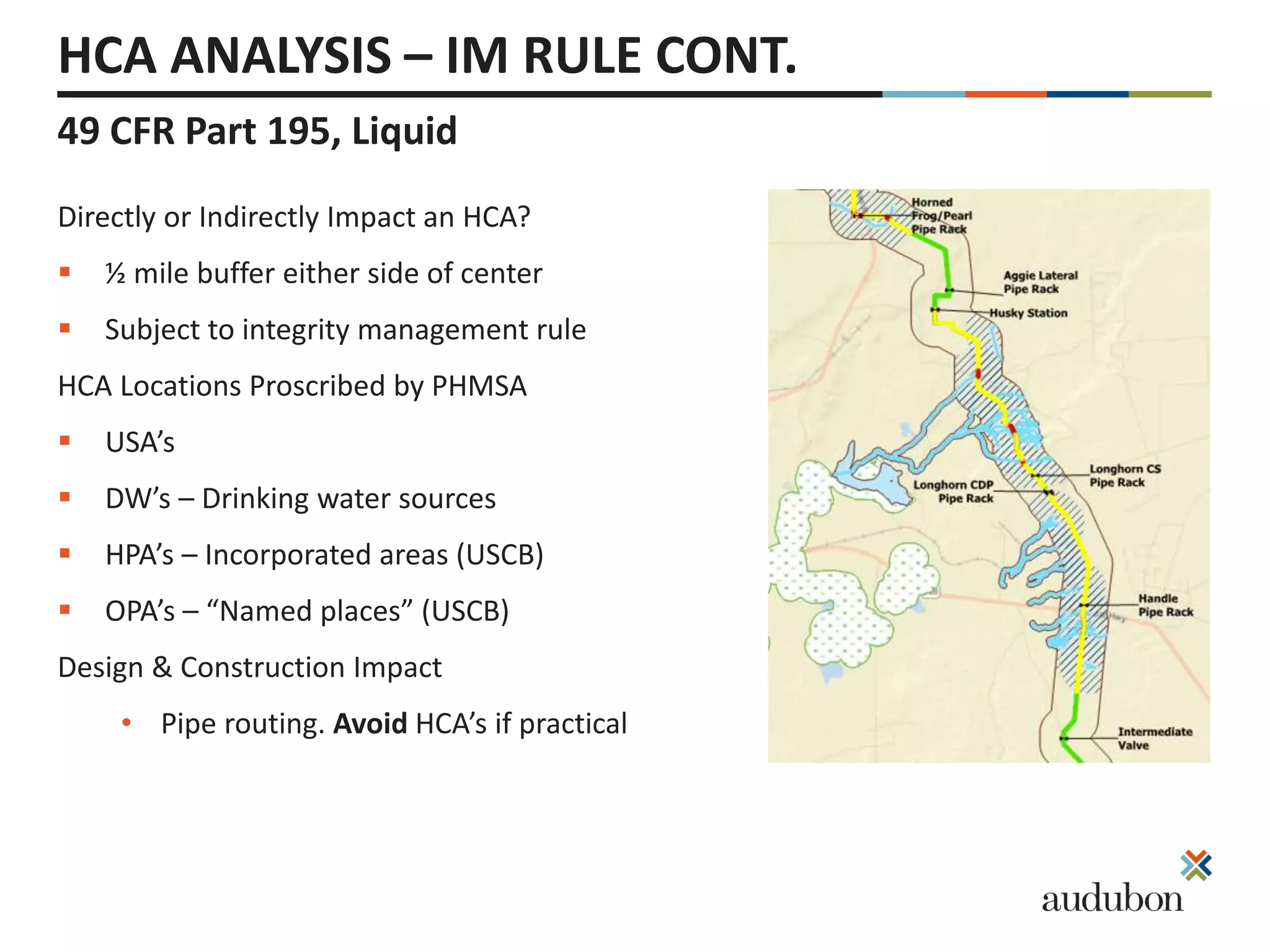

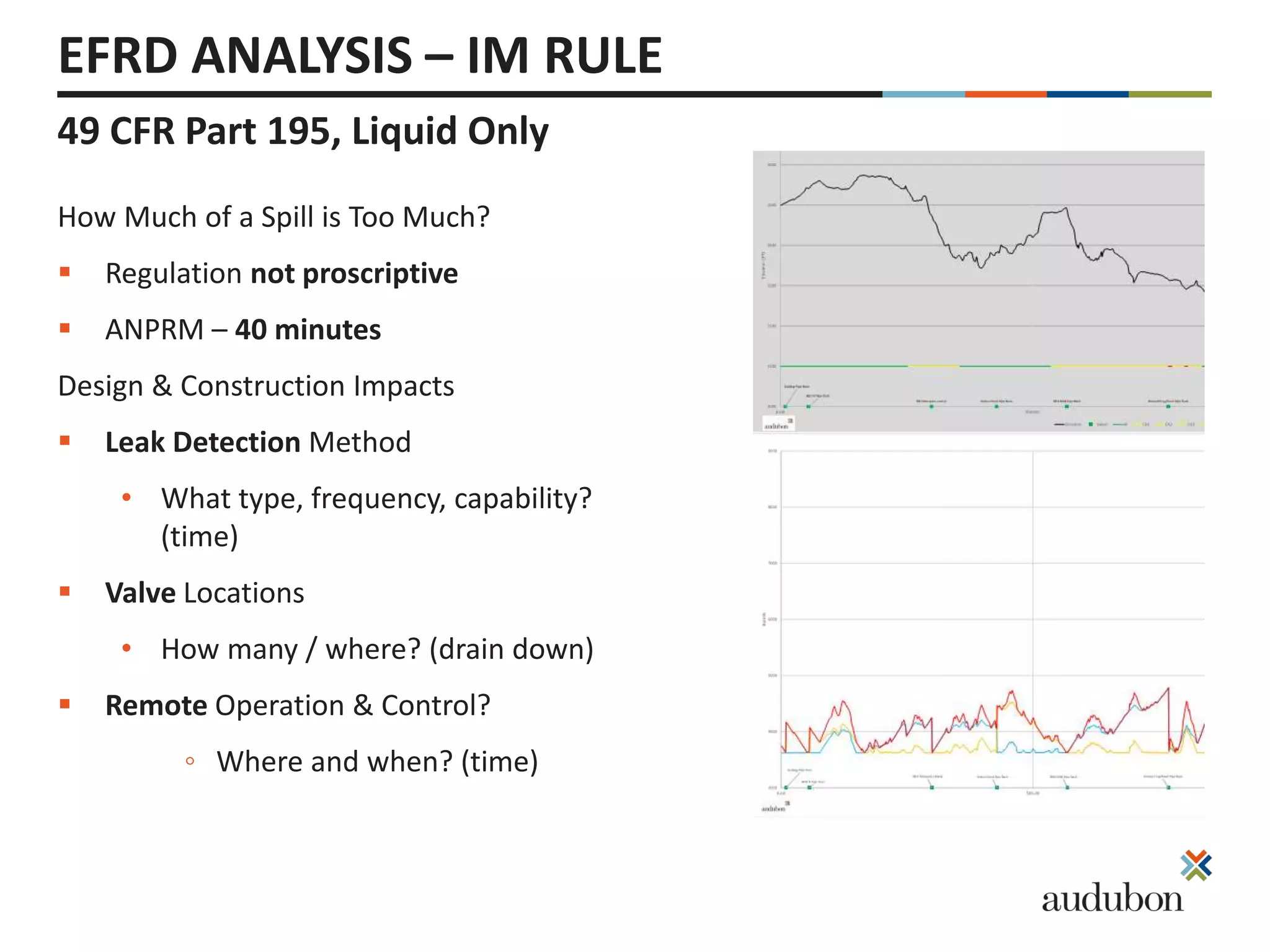

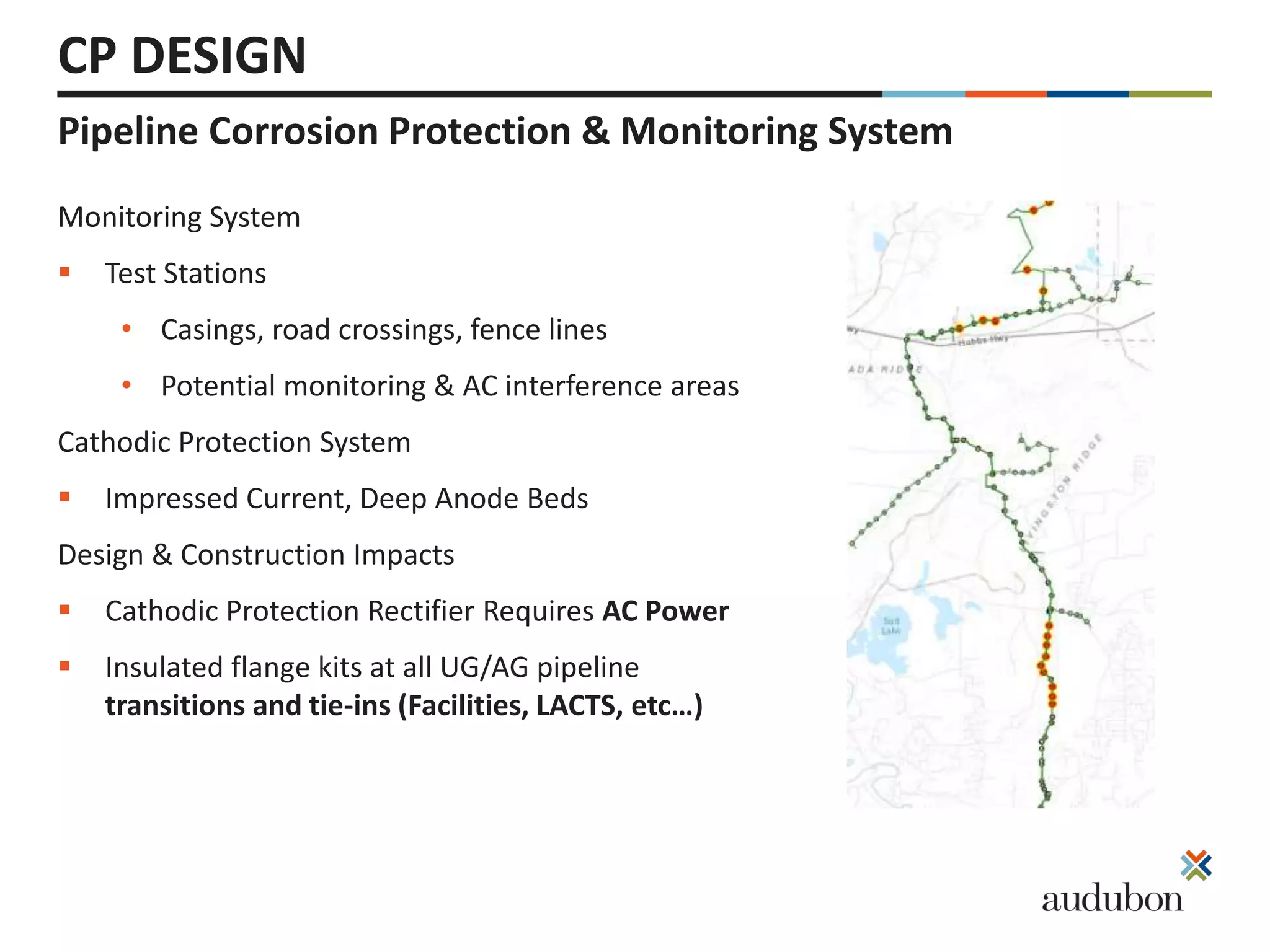

This document discusses the design and construction of new pipelines for compliance, integrity, and corrosion prevention. It covers safety statistics from 2017-2020 showing zero recordable incidents. The agenda discusses jurisdictional analysis to determine pipeline regulations, high consequence area analysis, emergency flow restriction devices, geohazard analysis, leak detection capability analysis, AC interference modeling, cathodic protection design, risk analysis, and installation and commissioning of cathodic protection and AC mitigation systems.