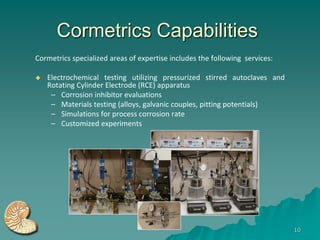

Ammonite Corrosion Engineering and Cormetrics Ltd. provide corrosion engineering and consulting services to oil and gas companies. They have over 300 years of combined experience in corrosion management. Services include Risk-Based Inspection programs, materials selection, failure analysis, and specialized laboratory testing to evaluate corrosion prevention chemicals and monitor corrosion. They have numerous oil and gas clients across Canada.