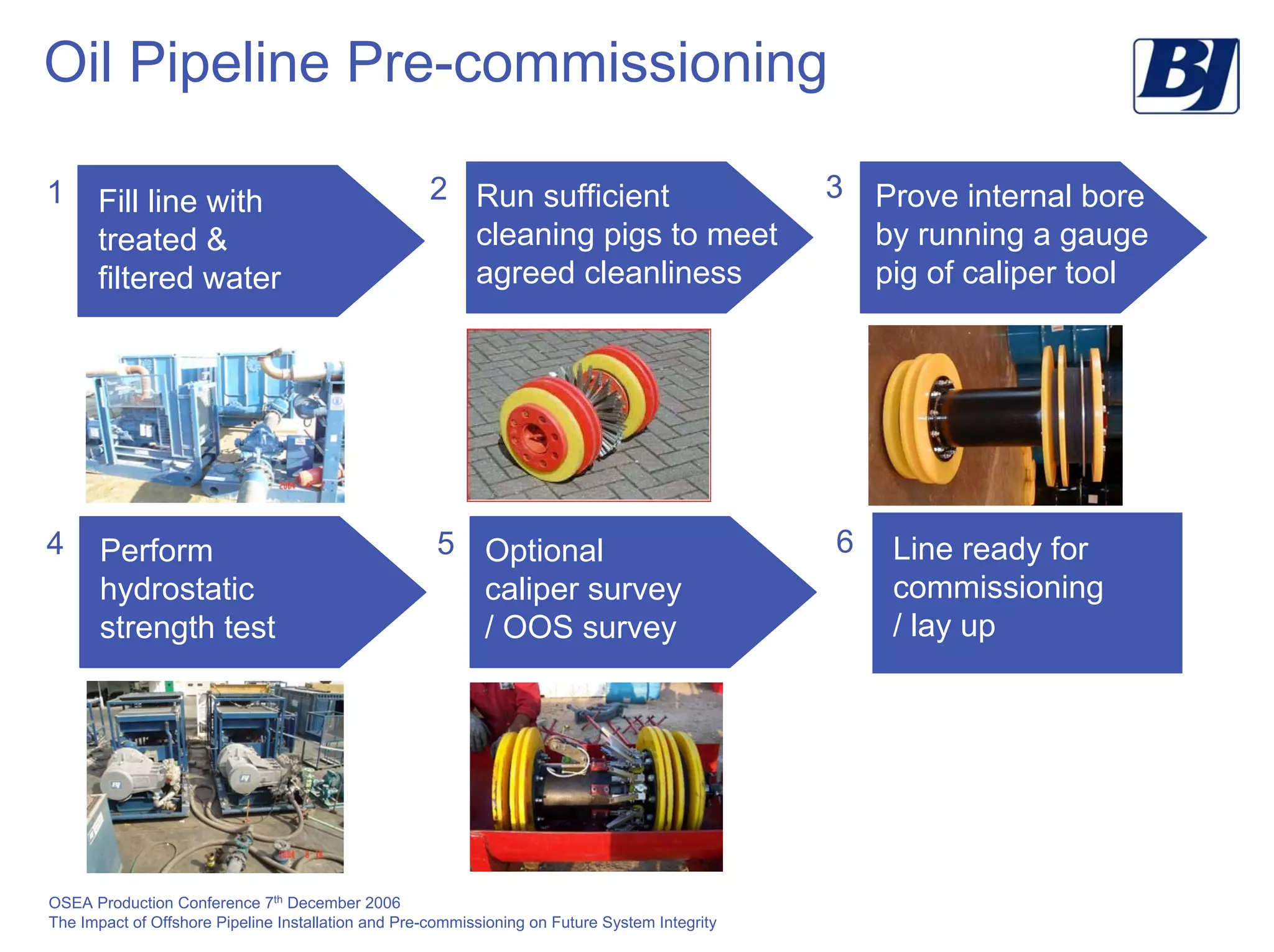

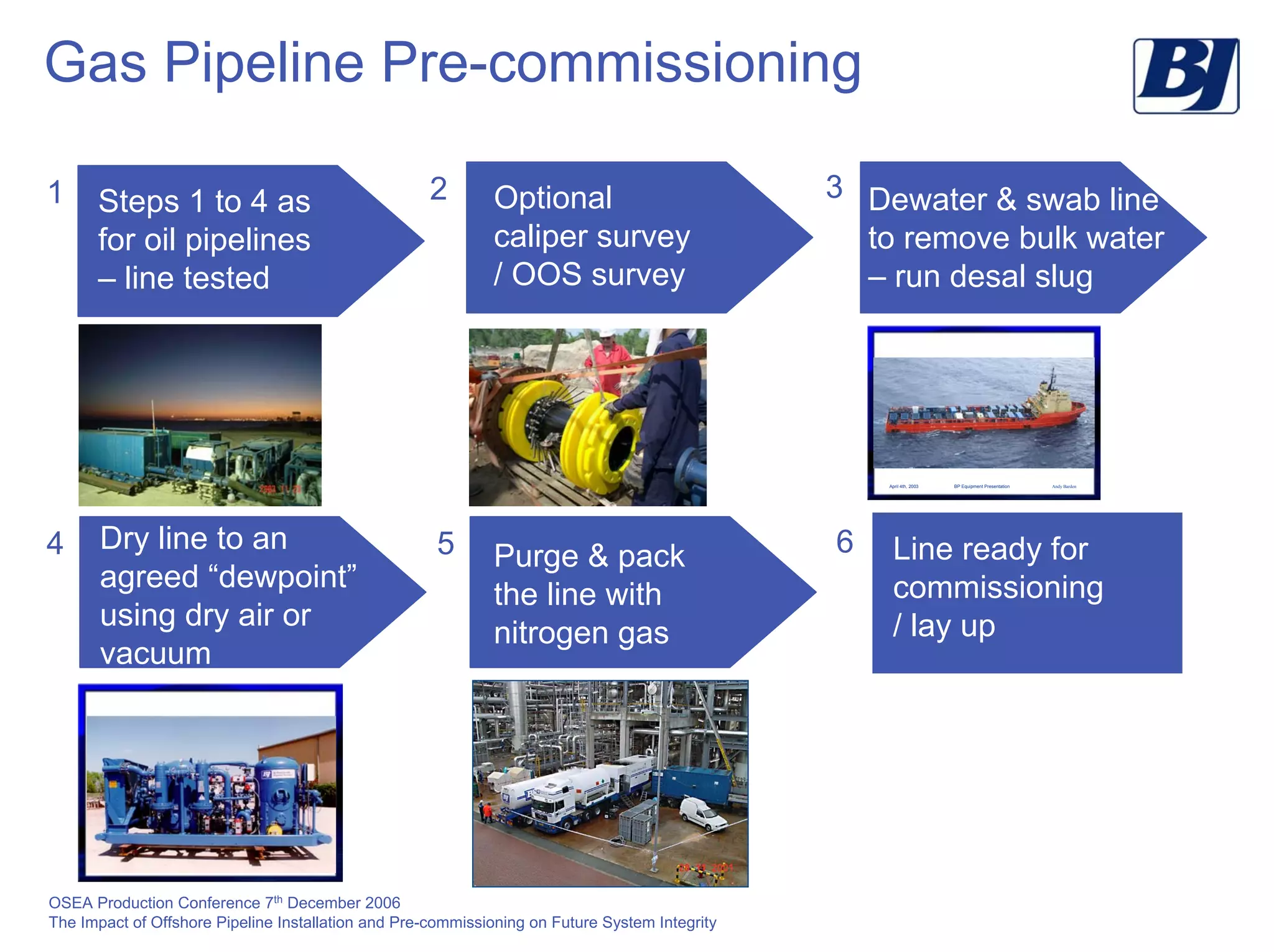

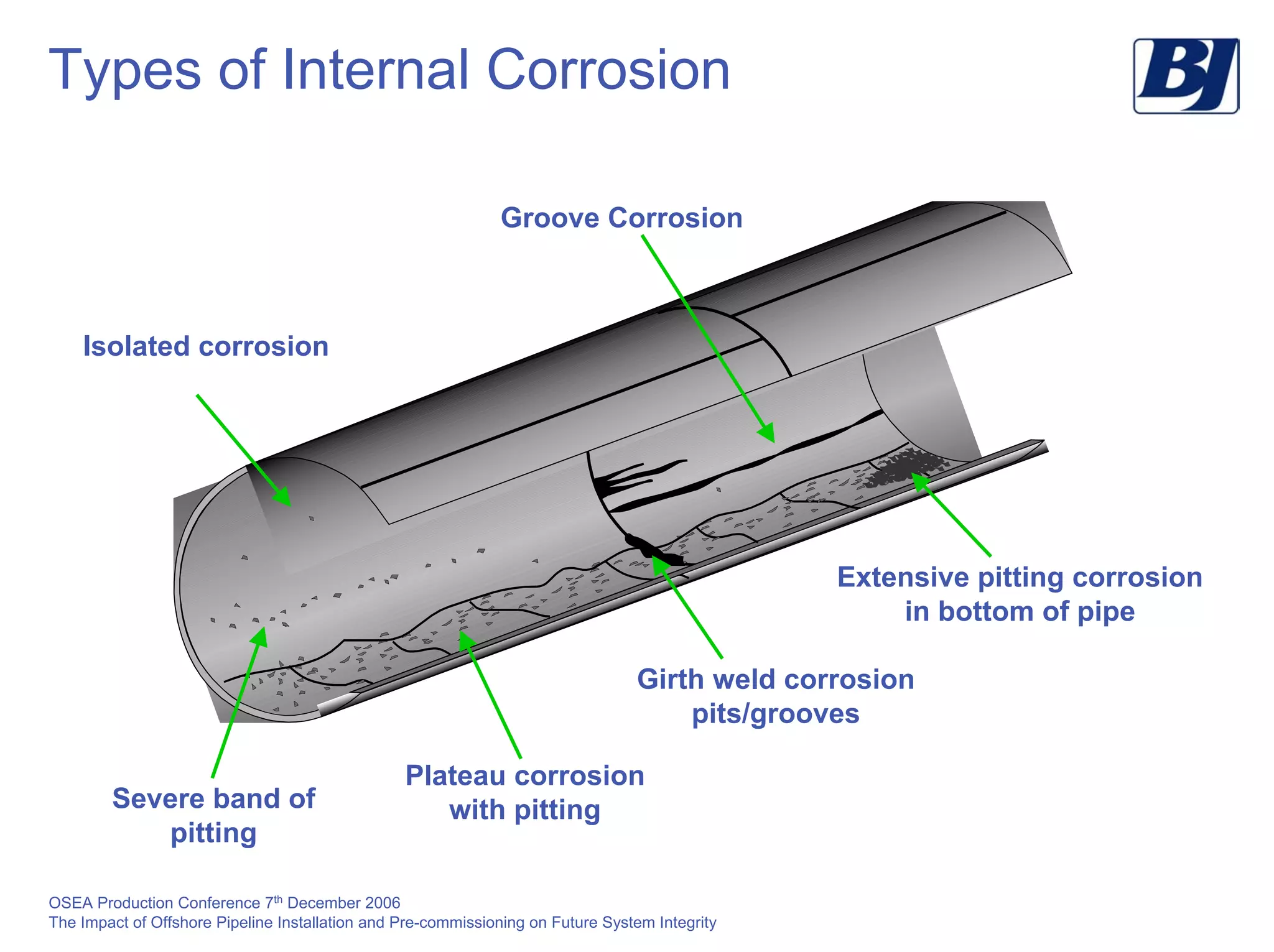

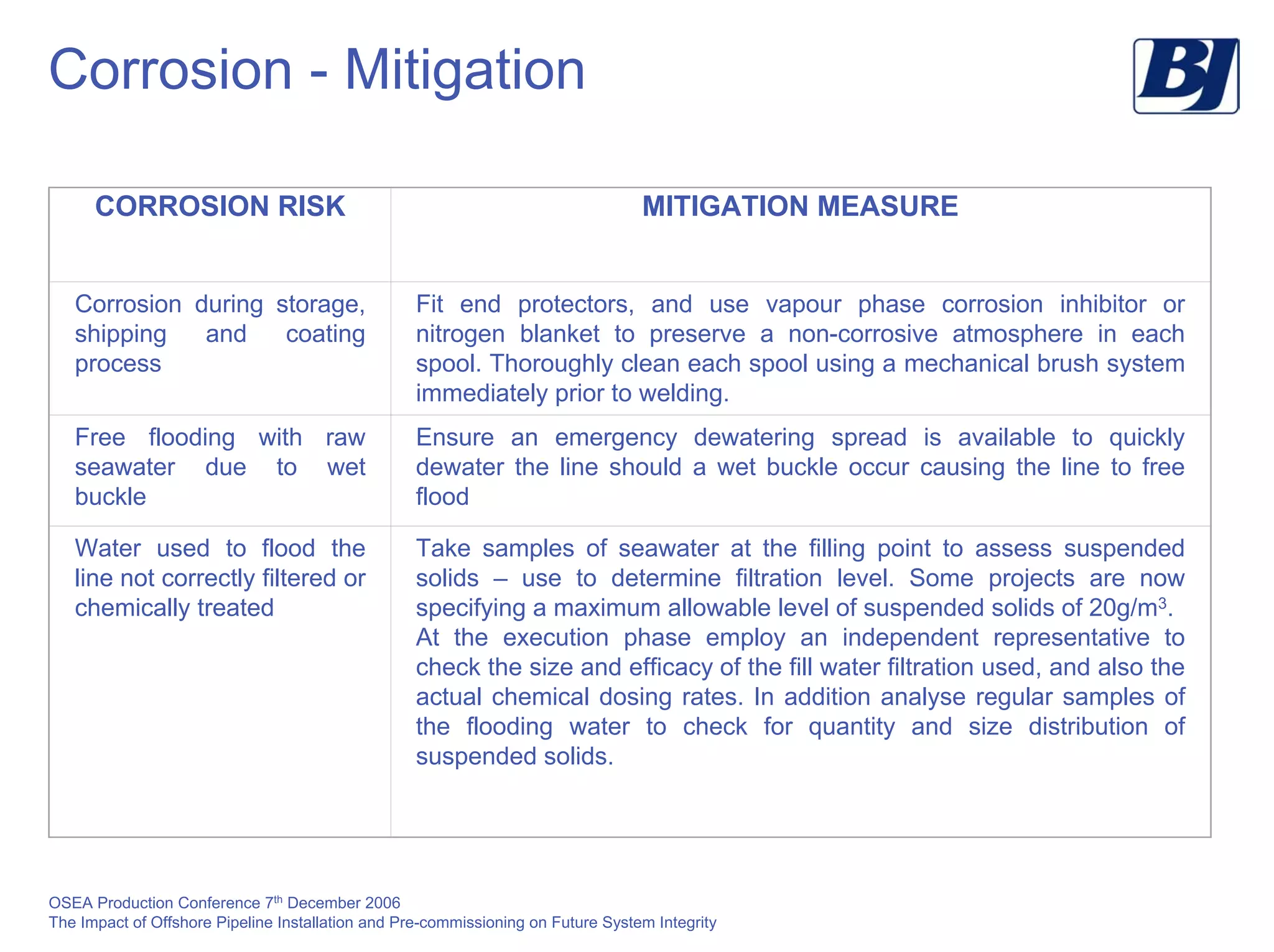

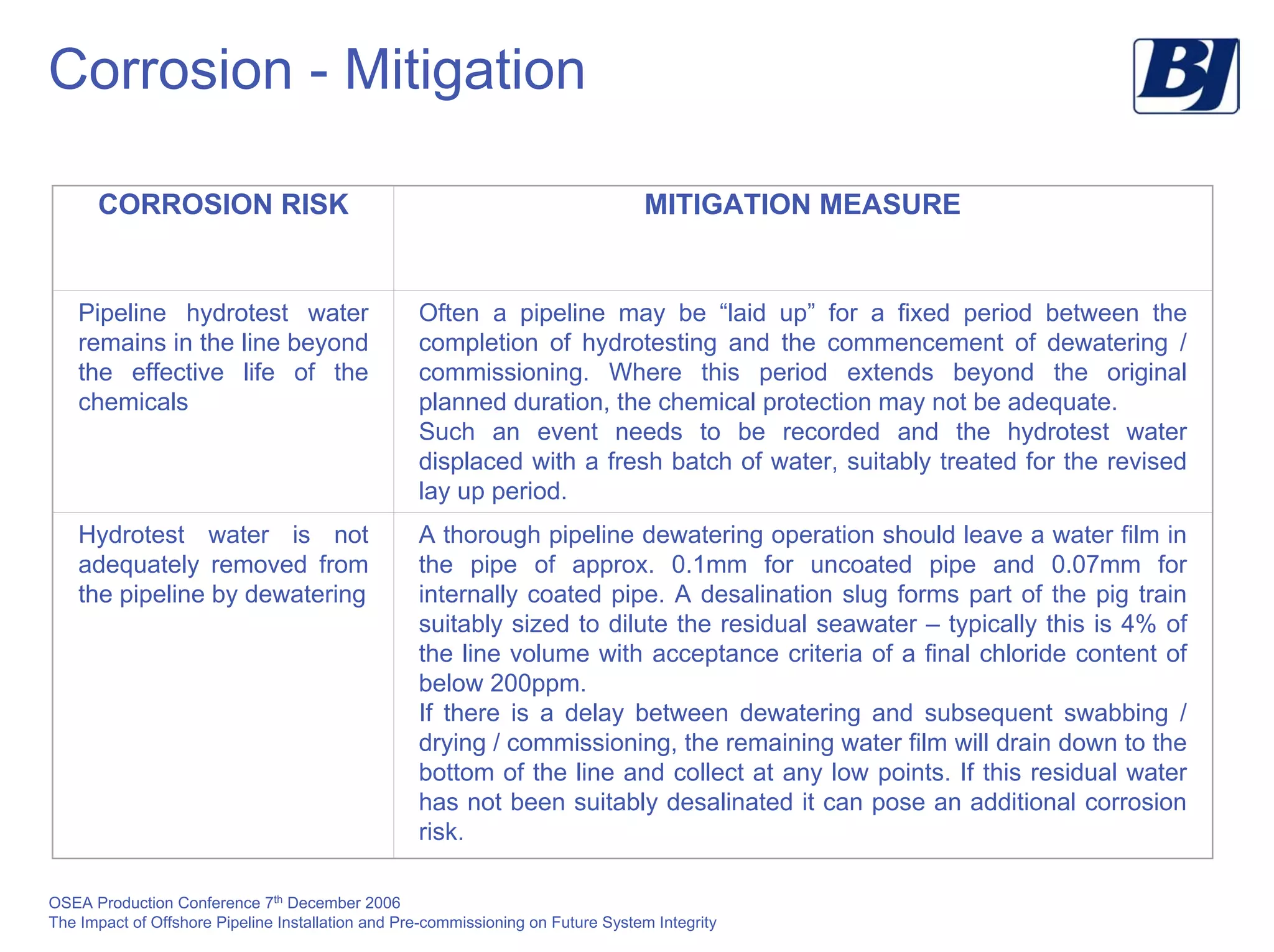

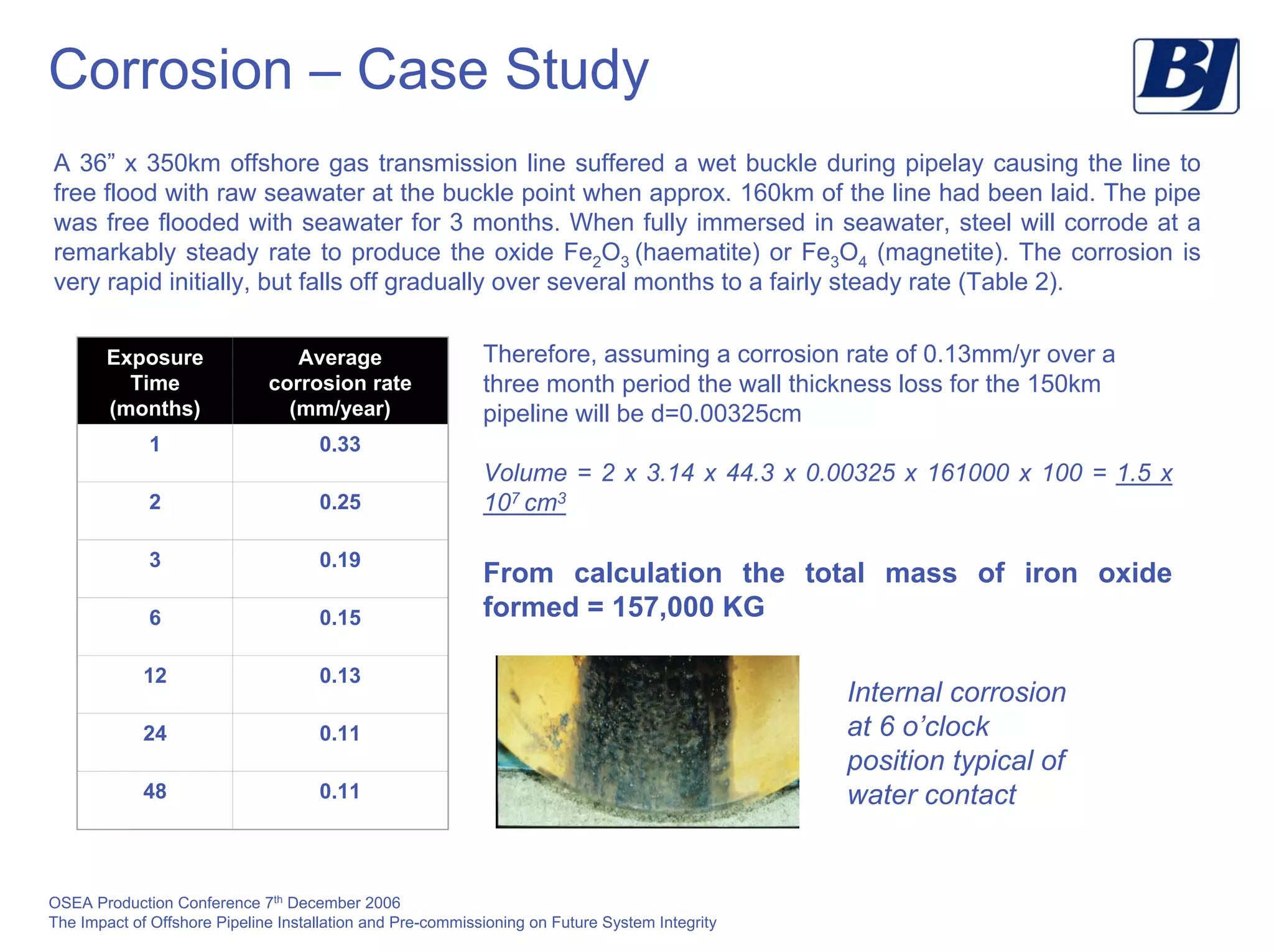

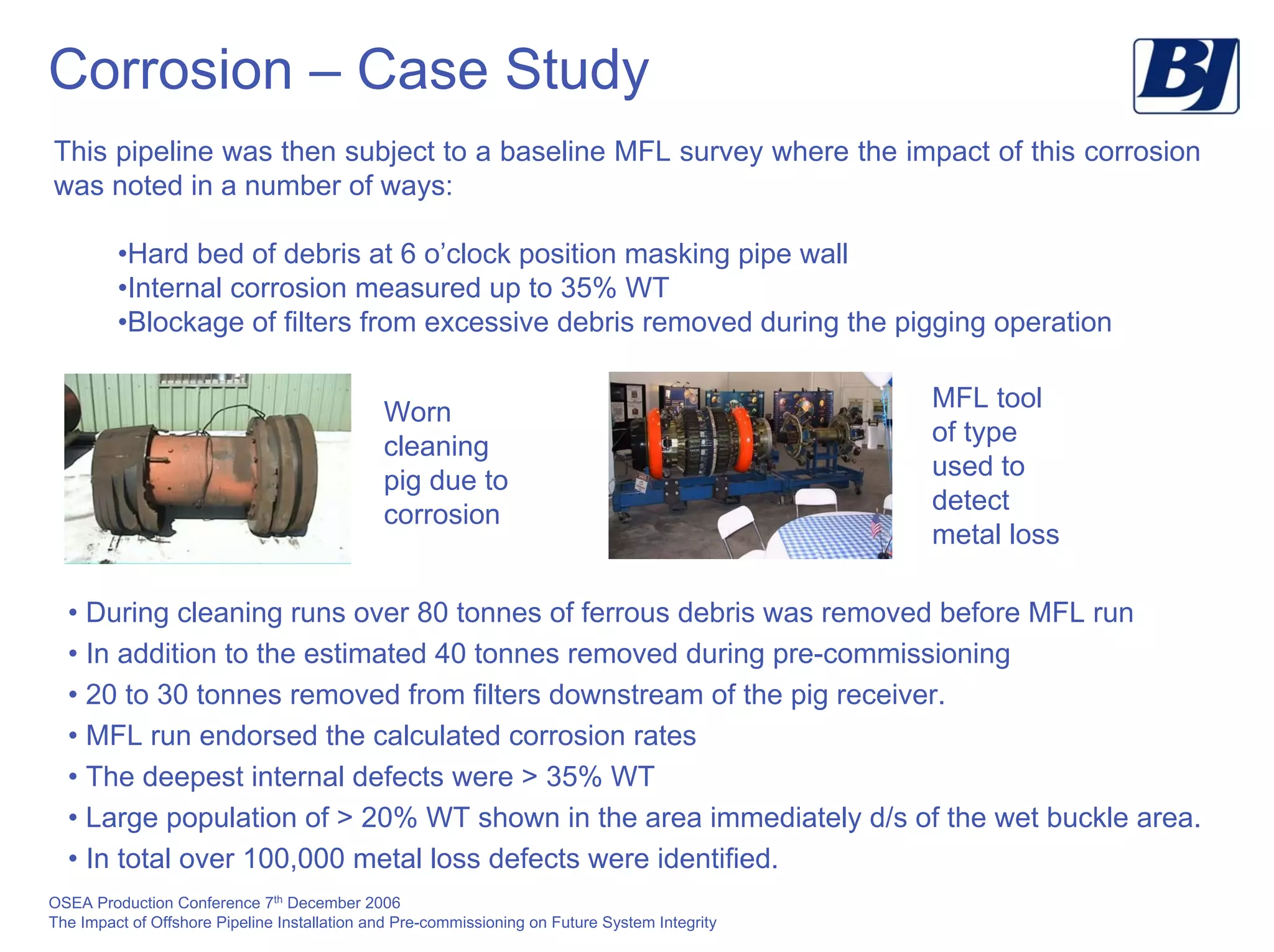

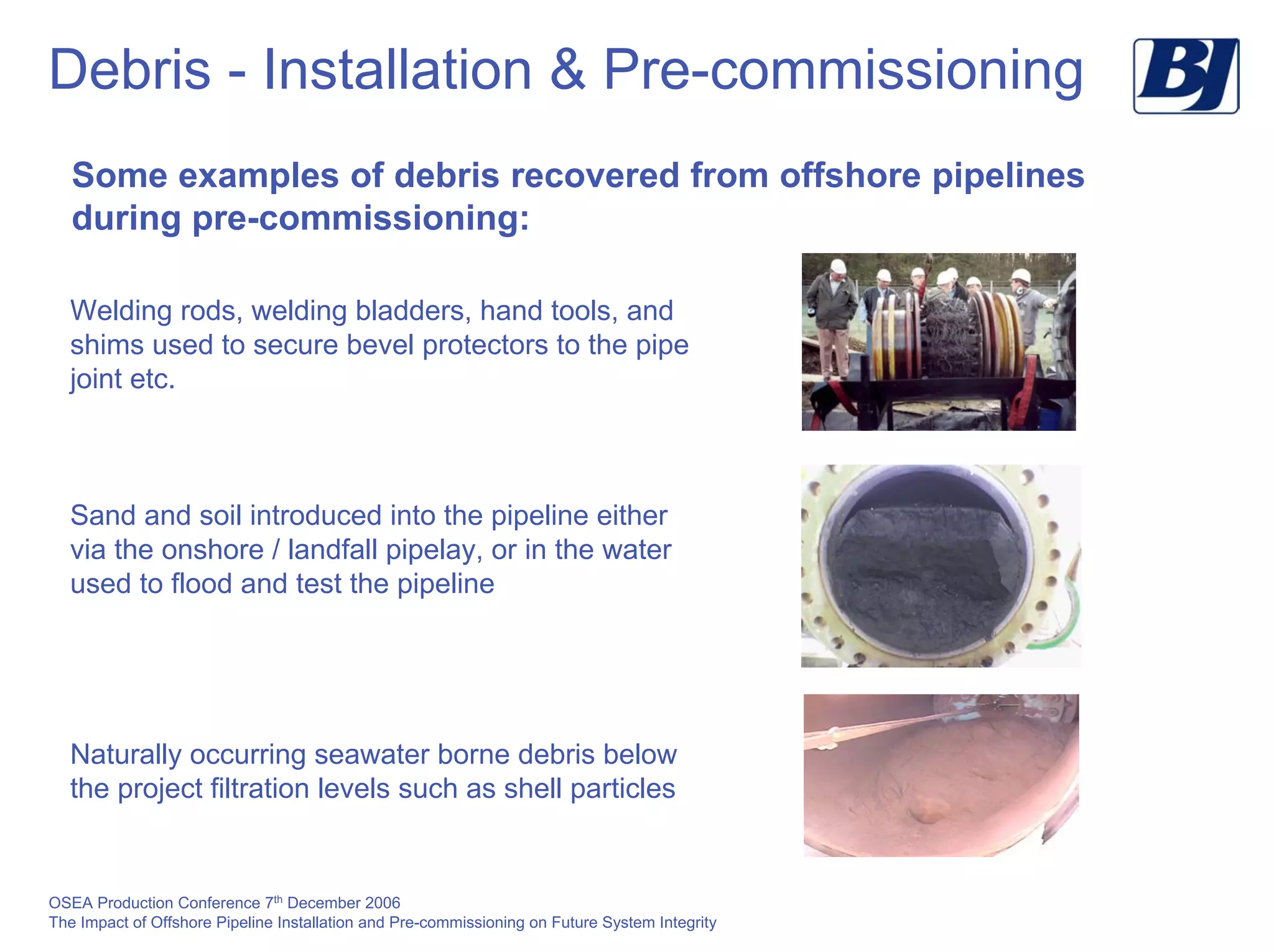

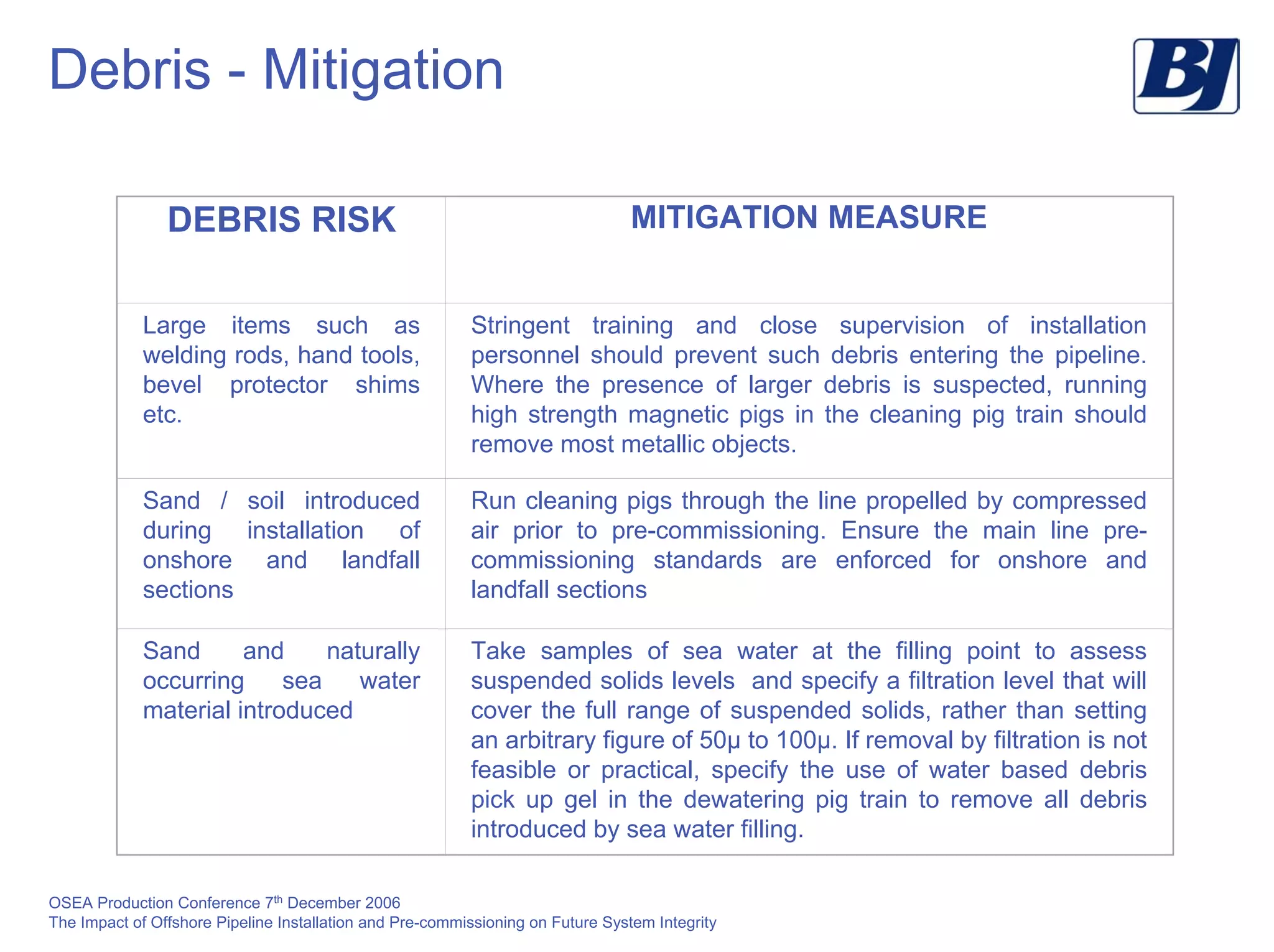

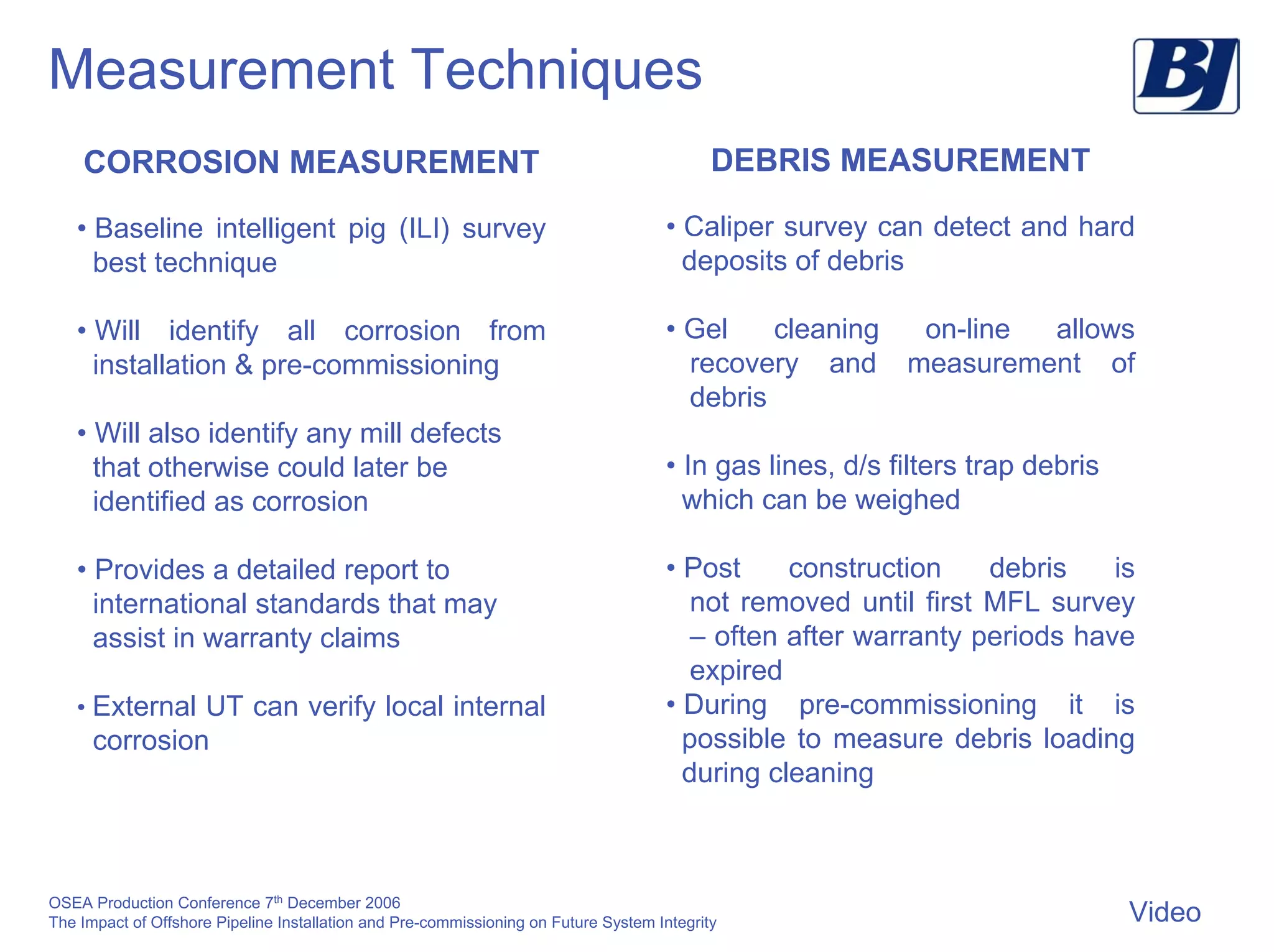

The document discusses the impact that offshore pipeline installation and pre-commissioning can have on future pipeline integrity. Specifically, it addresses how corrosion and debris during construction can negatively affect the pipeline. It provides case studies of pipelines that experienced significant corrosion or became blocked by debris due to issues with wet buckles, water quality, cleaning procedures, and more. The document emphasizes the importance of carefully planning and executing the pre-commissioning phase to avoid problems that compromise the long-term integrity of offshore pipelines.