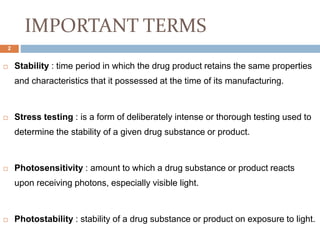

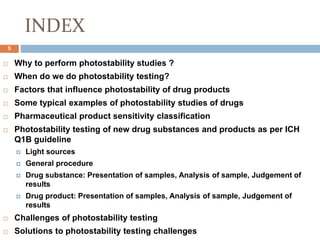

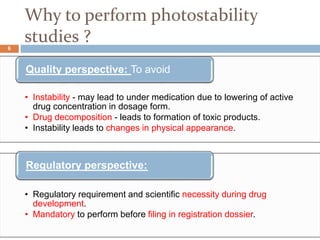

Photostability testing is performed to evaluate the stability of drug substances and products when exposed to light. It aims to identify necessary precautions to prevent unacceptable changes during manufacturing, formulation, or shelf life. The document discusses factors influencing photostability and provides examples. It outlines the process for photostability testing of both drug substances and products according to ICH guidelines, including presentation of samples, analysis, and judgement of results. Challenges in testing and solutions to ensure accurate light measurements and tight environmental control are also reviewed.