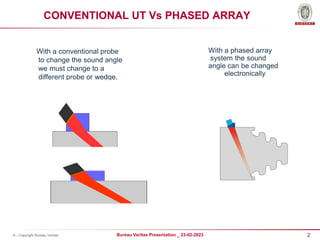

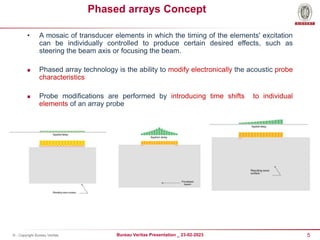

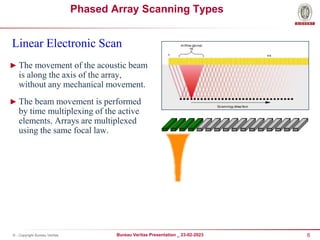

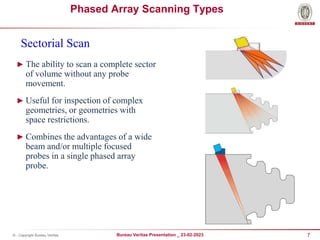

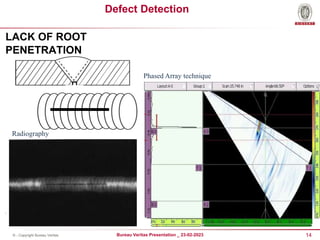

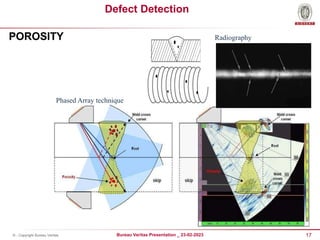

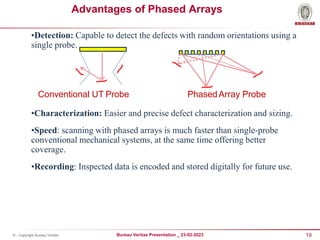

The document primarily discusses the advantages and functionalities of phased array ultrasonic testing (PAUT) compared to conventional ultrasonic testing (UT), highlighting its ability to electronically control sound angles and focus to improve defect detection. It outlines various scanning types, data display methods, and site requirements for effective implementation. Additionally, it emphasizes the benefits of faster scanning, better coverage, and precise defect characterization with phased arrays.