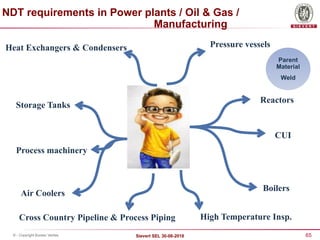

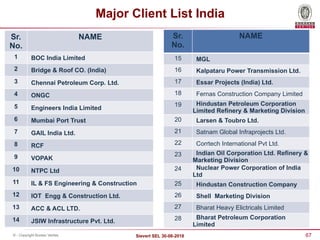

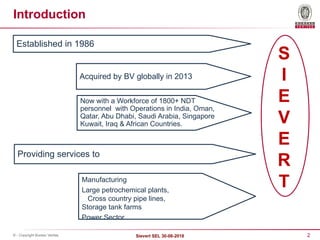

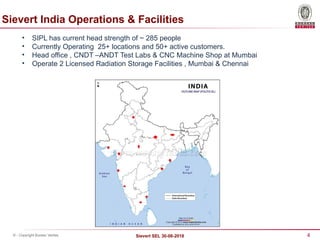

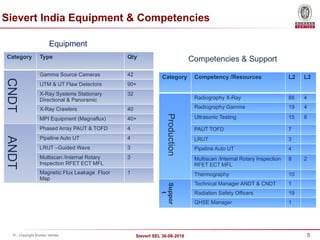

Sievert India Pvt. Ltd., established in 1986 and acquired by Bureau Veritas in 2013, specializes in non-destructive testing (NDT) and operates across multiple countries with a diverse workforce. The company offers various NDT services, including conventional and advanced techniques, and has extensive capabilities for inspecting oil, gas, and power sectors. With a robust operational framework and a wide range of equipment, Sievert India provides comprehensive inspection solutions to numerous active customers across more than 25 locations.

![24

Sievert SEL 30-08-2018

© - Copyright Bureau Veritas

AS[C] Scan

S

c

a

n

n

i

n

g

D

i

r

e

c

t

i

o

n

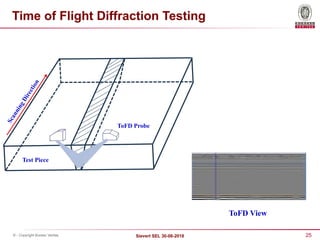

Test Piece

Phased Array Ultrasonic Testing](https://image.slidesharecdn.com/sipl-241109081622-6b609d54/85/sievert-india-private-limited-presentation-pptx-24-320.jpg)