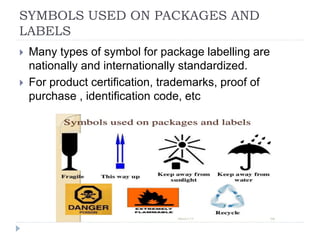

The document discusses pharmaceutical packaging, emphasizing its definition, importance, and ideal requirements for ensuring drug safety, stability, and compliance. It outlines different types of packaging materials, including glass, metals, rubbers, and plastics, along with their advantages and disadvantages. Additionally, the document covers packaging functions, types of closures, symbols used, and common defects in packaging.